Labor-saving torsion spring vehicle seat

A technology of torsion spring seat and torsion spring, which is applied in the field of seat, can solve the problems of poor anti-vibration effect and laborious riding, and achieve the effects of labor-saving riding, good anti-vibration effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

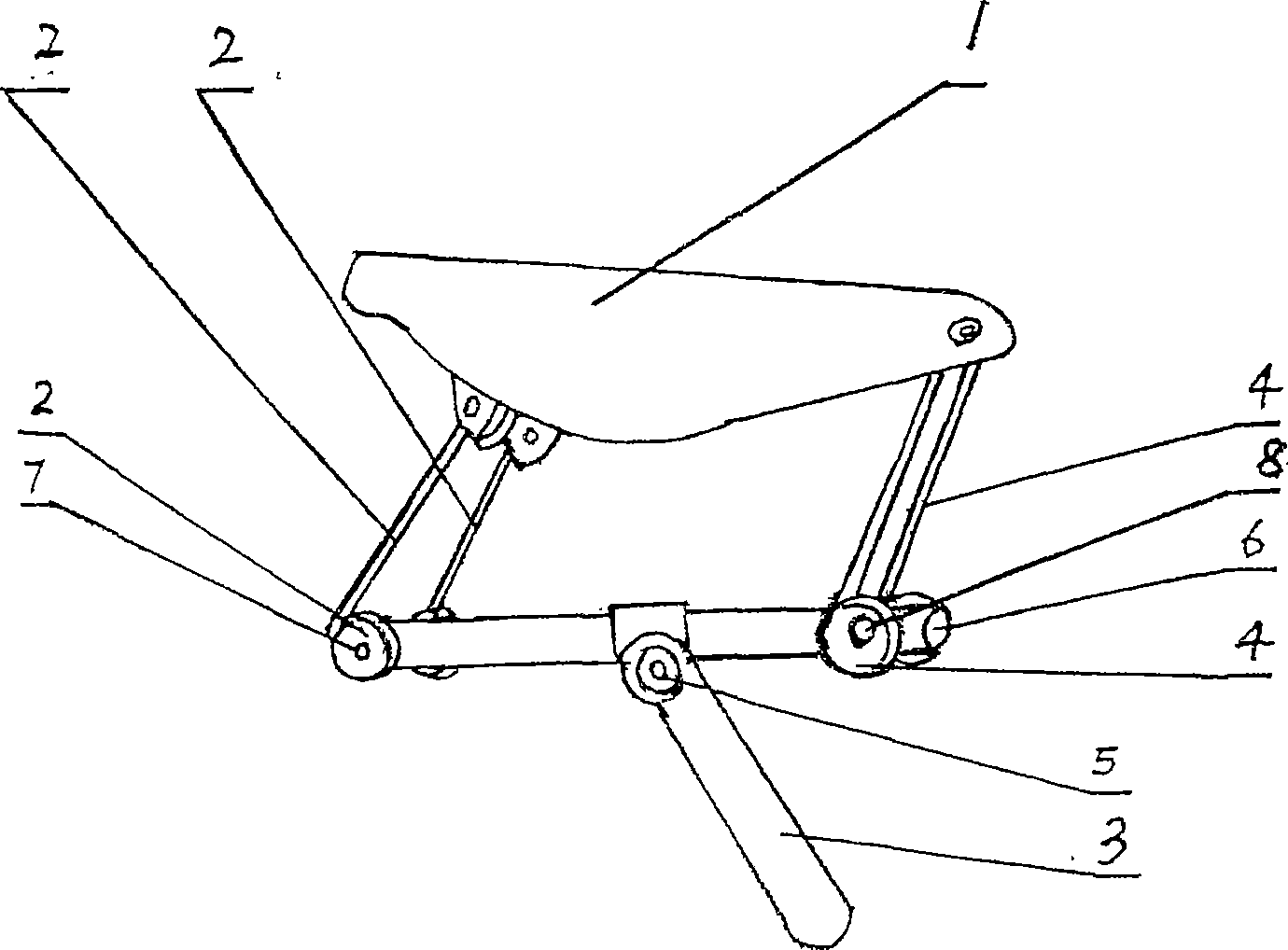

[0009] The present invention comprises a vehicle seat surface 1, a vehicle seat pole 3, a rear torsion spring 2, a front torsion spring 4, and a horizontal tube 6, the vehicle seat surface 1 is connected to the horizontal tube 6 through the rear torsion spring 2 and the front torsion spring 4, The seat pole 3 is connected to the middle part of the cross tube 6 through the fixed shaft 5 .

[0010] The rear torsion spring 2 is symmetrically arranged on both sides of the rear end of the horizontal tube 6 through the pivot pin 7 , and the front torsion spring 4 is symmetrically arranged on both sides of the front end of the horizontal tube 6 through the axis 8 . The rear torsion spring and the front torsion spring can adopt double torsion springs.

[0011] When in use, the rider's buttocks are pressed and pulled, and they move up and down in accordance with the movement rhythm of the legs, and the upper body also rises and falls with the seat surface to assist the legs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com