Complete-releasing-light hydrocarbon automatic sample handling system

An automatic sampling, light hydrocarbon technology, applied in the field of fully de-light hydrocarbon automatic sampling system, can solve the problems of the difference of the two injections, the injury of the operator, the easy pollution of the observation window and the gas storage tank, etc., to improve the analysis performance, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

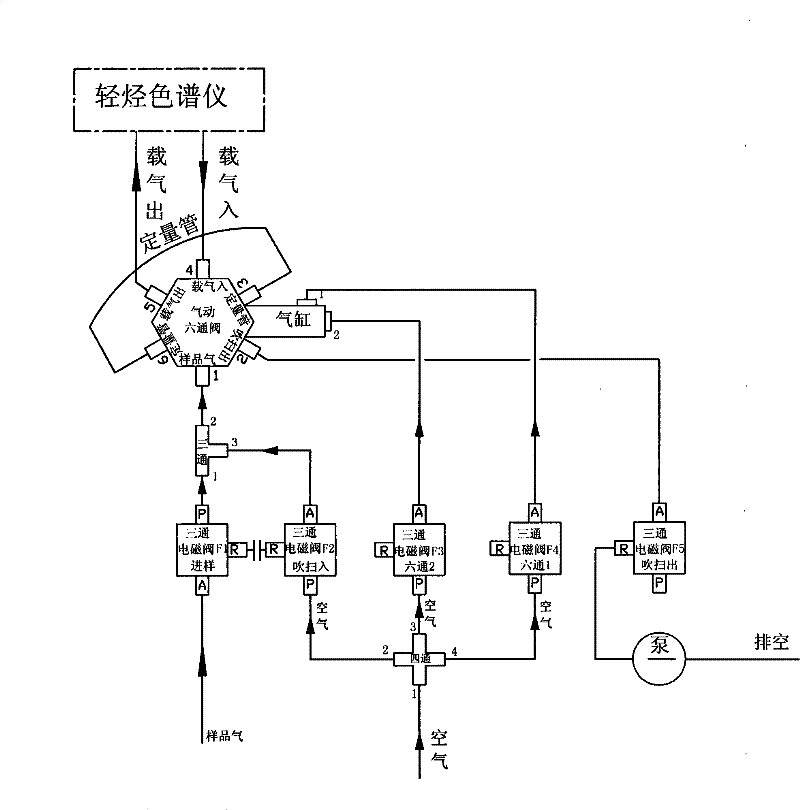

[0011] The present invention adopts the 220V / 150W heating plate of Dongtai Tianbao Far Infrared Instrument Factory, the QH-7610 pneumatic six-way valve of Beijing Baili Company, the PM950.2 micro-vacuum pump of Chengdu Ruiyi Machinery Design Center, and the 2KA05 of Beijing Zhongkai Yongchen Technology and Trade Co., Ltd. -S5S15NT, 2504SN power module, R220D10 solid state relay of Hangzhou Xizi Solid State Relay Co., Ltd., SVD113 three-way solenoid valve of South Korea SANWO Pneumatic Component Company and W77E58 single chip microcomputer as examples for further explanation.

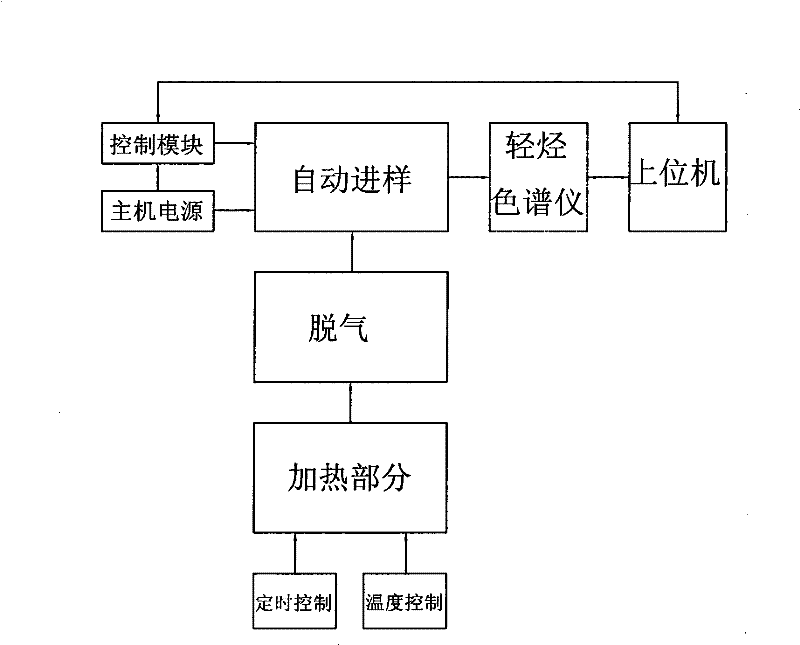

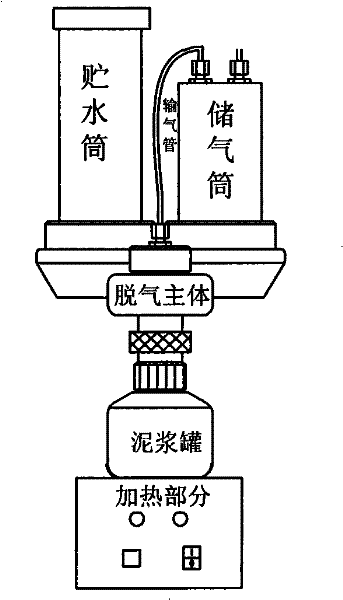

[0012] like figure 1 As shown in , the degassing part is timing control, temperature control and heating part are connected together, the sample gas containing hydrocarbons is separated from the mud by the method of temperature and timing control heating, and the computer issues instructions to control the complete degassing- The sampling action of the automatic sampling part of the light hydrocarbon aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com