Papermaking method and papermaking machine

A technology for paper machines and paper, applied in the direction of thin paper/absorbent paper, paper, papermaking, etc., can solve the problem of not considering the reduction of water consumption, etc., and achieve the effect of improving production efficiency, improving productivity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

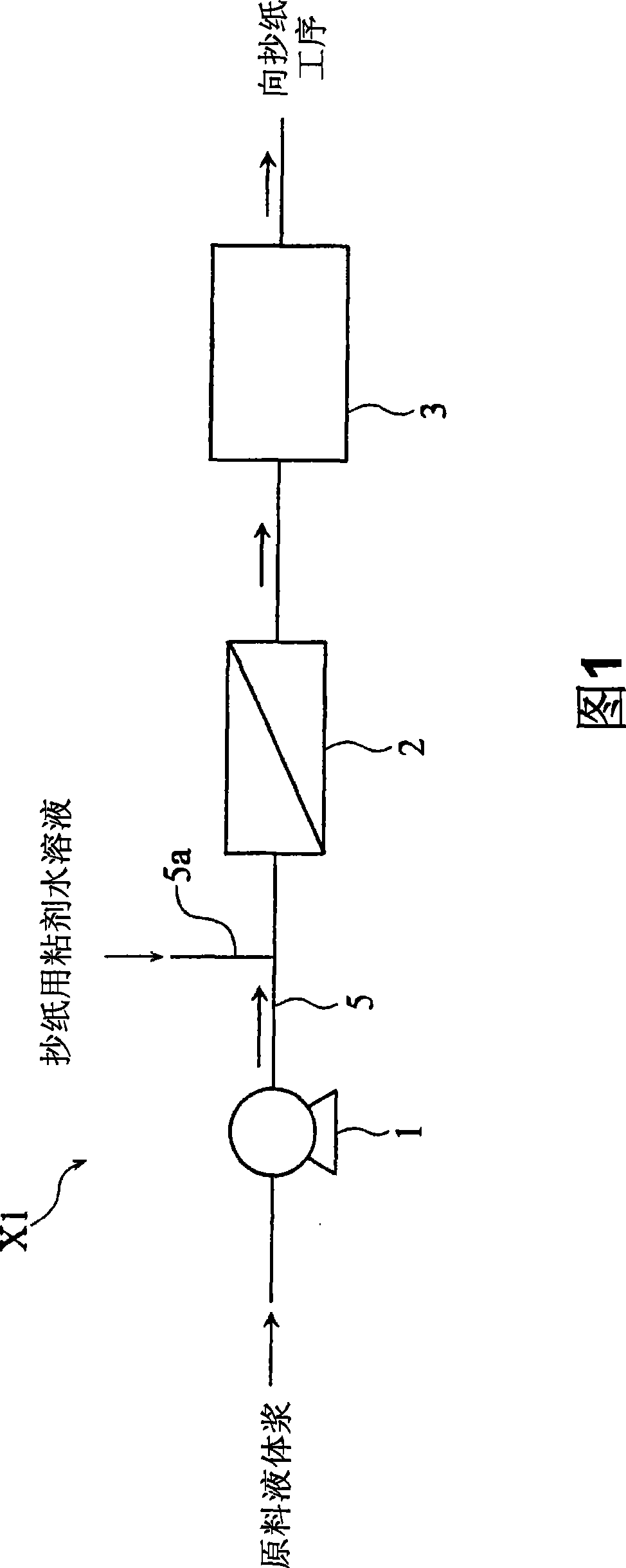

[0052] (papermaking method)

[0053] Paper is produced from raw material liquid slurry using the apparatus according to the above-mentioned embodiment. In this embodiment, the paper machine uses a crescent former paper machine, with a papermaking speed of 1300m / min (reel speed of 1100m / min), and a papermaking unit area weight of 13g / m 2 run under thin paper conditions. NBKP (conifer pulp) / LBKP (broadleaf pulp)=40 / 60 (weight ratio) with a beating degree of 640 mlcsf (Canadian Standard Freeness) was used as a raw material liquid slurry of 0.15% by weight as the raw material for papermaking. Use polyethylene oxide (trade name: PEO-18Z, aqueous solution viscosity: 430mPa·s (0.5%), manufactured by Sumitomo Seika Co., Ltd.) as the adhesive for papermaking. A 0.5% by weight polyethylene oxide aqueous solution was prepared using the viscous aqueous solution. The polyethylene oxide aqueous solution was added to the pipe 5 between the pump 1 and the screen 2 to make paper. The usage...

Embodiment 2

[0059] In this example, polyethylene oxide (trade name: PEO-27, manufactured by Sumitomo Seika Co., Ltd.) having a viscosity of 720 mPa·s in a 0.5% by weight aqueous solution was used. As an adhesive for papermaking. Papermaking was performed under the same conditions as in Example 1 except for the type of adhesive for papermaking. The usage-amount of the binder for papermaking was 0.11% by weight with respect to the dry weight of the paper produced|generated. Table 1 shows the results of the paper obtained in this example, the confirmed texture, and the amount of water used.

Embodiment 3

[0061] In this example, papermaking was performed under the same conditions as in Example 2 except that 0.1% by weight of polyethylene oxide was used as the binder for papermaking. The usage-amount of the binder for papermaking was 0.13% by weight with respect to the dry weight of the paper produced|generated. Table 1 shows the results of the paper obtained in this example, the confirmed texture, and the amount of water used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com