Electromagnetic hydraulic valve type spring hydraulic operating mechanism having self-defense capability

An operating mechanism and spring hydraulic technology, applied in the field of power transmission and transformation, can solve problems such as large errors, inability of the mechanism to store energy normally, failure to meet the operating conditions of the circuit breaker, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

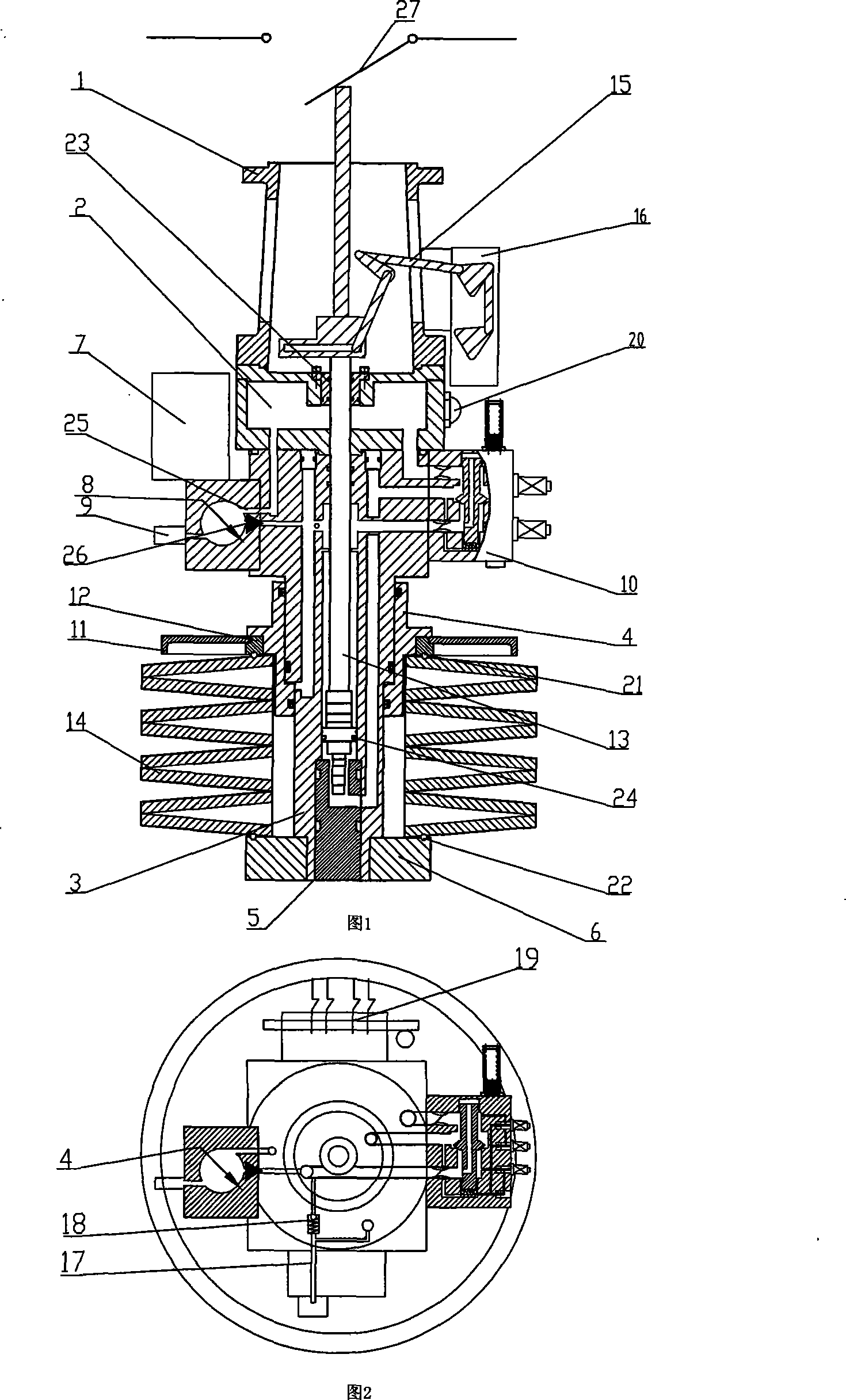

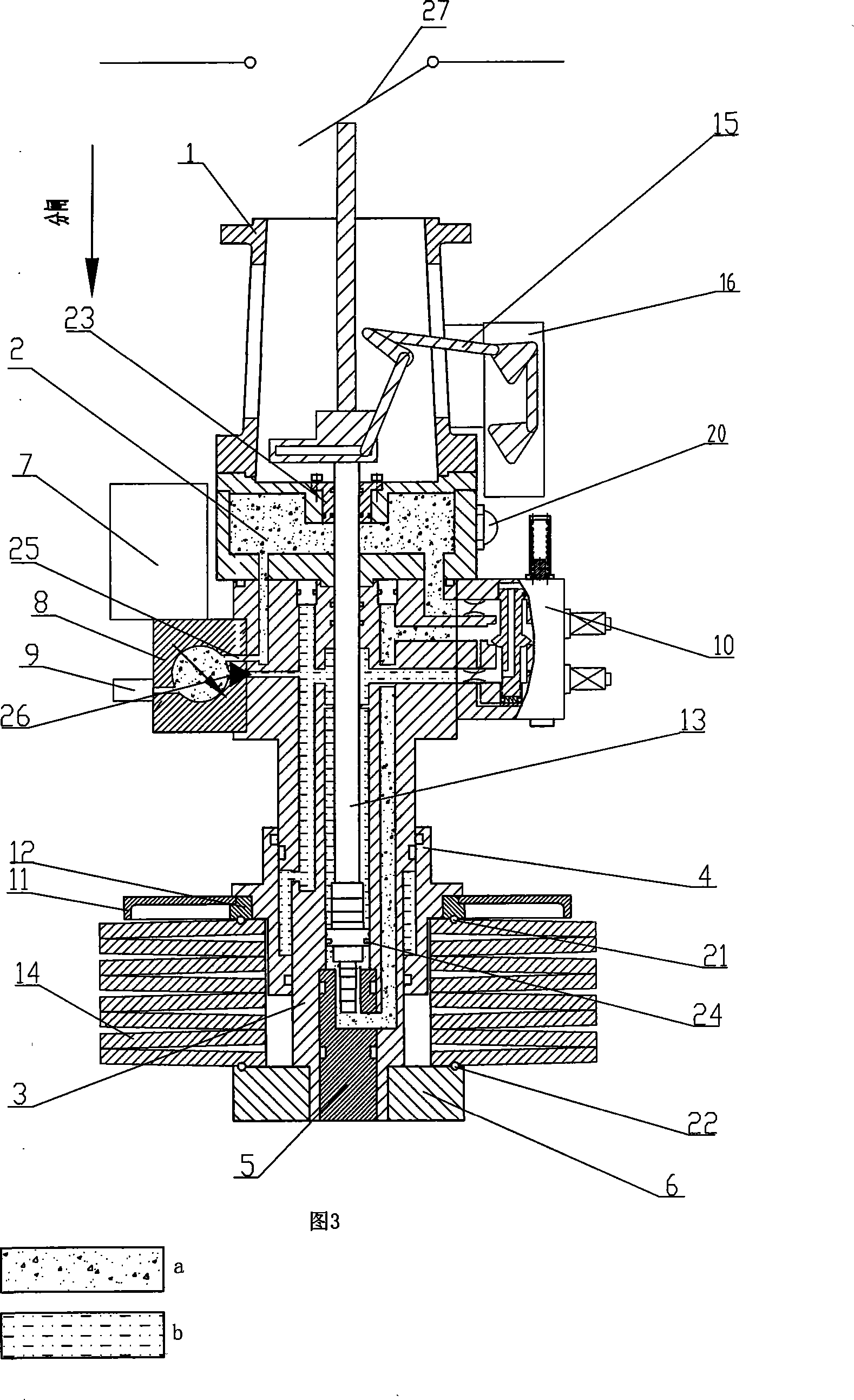

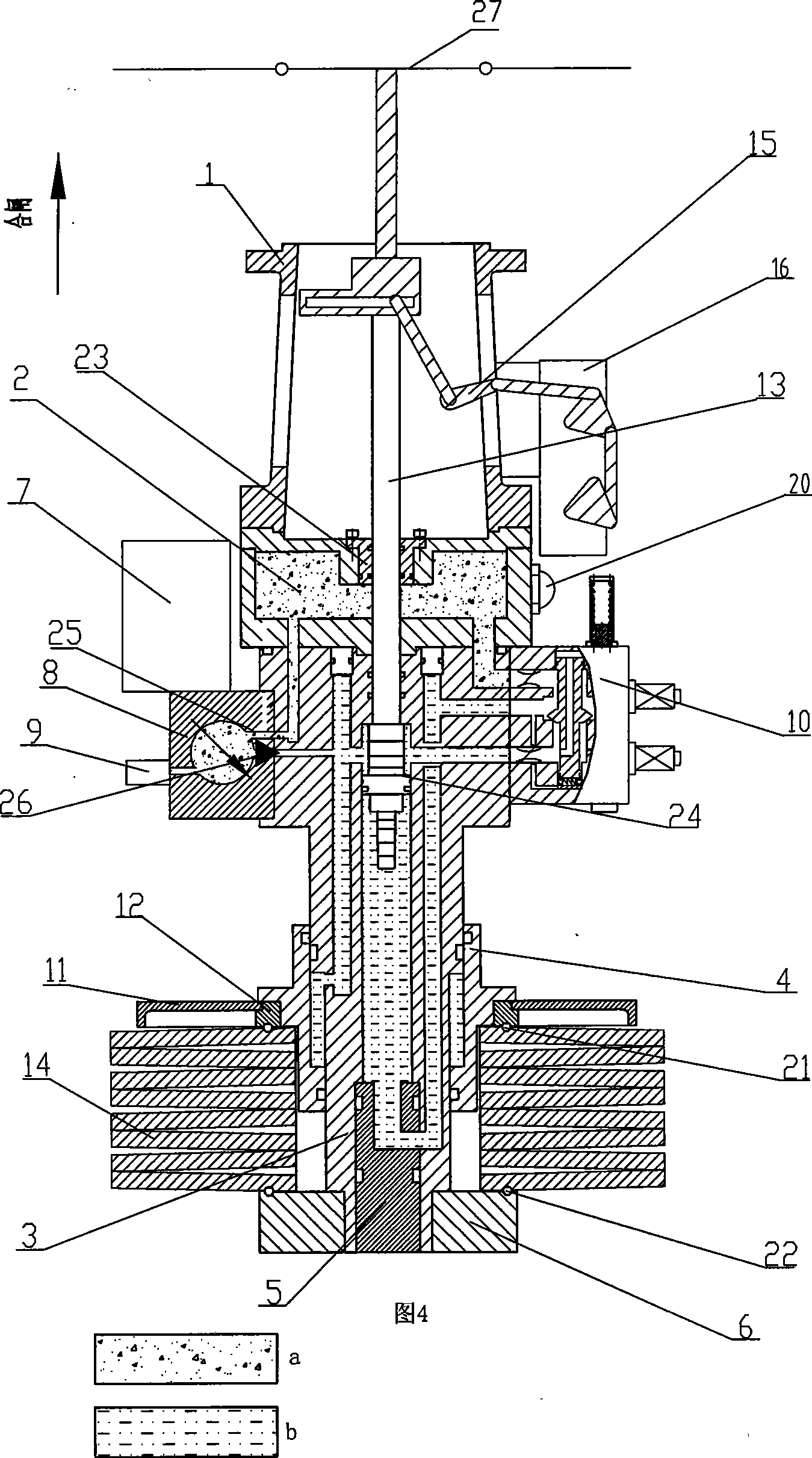

[0082] The spring hydraulic operating mechanism with self-defense capability is shown in Figure 1, Figure 2, Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the side of the support 1 is connected to the auxiliary switch 16, the lower end of the support 1 is fixed on the low-pressure fuel tank 2, the side of the low-pressure fuel tank 2 is provided with an oil mark 20, the bottom end of the low-pressure fuel tank 2 is sealed and connected to the working cylinder 3, and the upper end of the working cylinder 3 The outer surface is connected with the oil pump 8 , the electromagnetic hydraulic valve 10 and the safety relief valve 17 , wherein the oil pump 8 is connected with the working cylinder 3 through the oil pump connection groove 36 . The oil tank pump interface of the low-pressure oil tank 2 communicates with the upper opening of the oil pump channel of the working cylinder 3, the oil tank low-pressure oil interface of the low-pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com