Draining and filtering net, particularly for geotechnical applications

A filter and mesh technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of lack of mechanical strength, hindering correct excretion, and equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

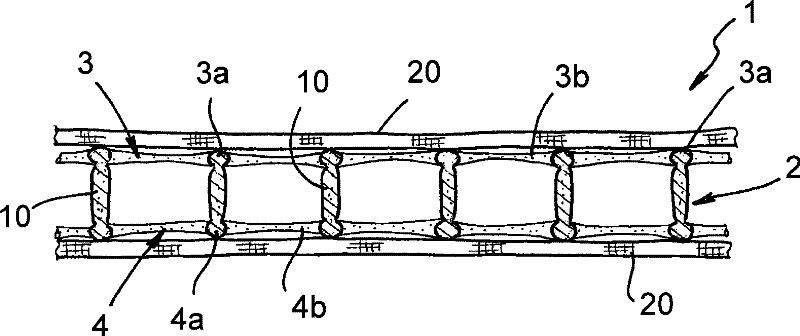

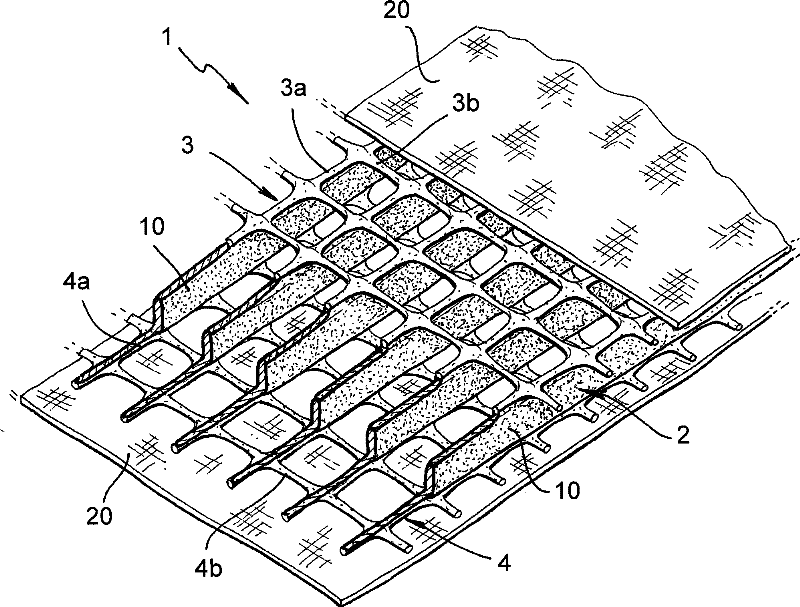

[0018] Referring to the drawings, a drainage and filter screen according to the present invention, in particular for geotechnical applications, is generally designated by the reference numeral 1 and comprises an intermediate layer 2 and a first outer layer 3 and a second outer layer 4, the two outer layers The layers are applied on opposite sides of the intermediate layer.

[0019] Preferably, but not necessarily, the mesh is made of high density polyethylene, as polyethylene has been found to be a suitable polymer for geotechnical applications, which can be blended with optional additives to form the final use and related commercial requirements. Determined mechanical and color properties.

[0020] The intermediate layer 2, which is essentially the basic element for ensuring good mechanical and hydraulic properties of the web, consists of a plurality of continuous filaments, designated by the reference number 10, which are arranged side by side with each other to actually for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com