Horizontal type etherifying reactor

A technology of chemical reaction and horizontal ether, applied in the field of horizontal etherification reactor, can solve the problems of increasing process pipeline, instrument control investment, unable to ensure complete homogeneous mixing of materials, and failing to increase the annual output of a single reactor. , to avoid dead zone or low-speed motion zone, good self-lubricating performance, long-term stable operation guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] As shown in Figures 1 to 2, a horizontal etherification reaction kettle is mainly composed of a jacket 16 inside a cylinder 17 to form a kettle body 3. The cylinder 17 is connected and fixed with the bottom frame 11. 17 two ends are installed cylinder head 26, and cylinder head 26 adopts flat-bottomed head, and flat-bottomed head is used for sealing kettle body 3. A rotating agitator 5 is arranged in the center of the kettle body. The agitator shaft 5 penetrates from the right end of the kettle body 3 until it extends out from the left end. 2 and the right end shaft seal box 6 are respectively connected with the left bearing seat 1 and the right bearing seat 7, the stirring shaft is supported by the left bearing seat 1 and the right bearing seat 7, and the left bearing seat 1 and the right bearing seat 7 are respectively fixed with the base frame 11. A plurality of coulter-type agitators 4 are staggeredly installed on the stirring shaft 5, and the coulter-type agitators...

Embodiment 2

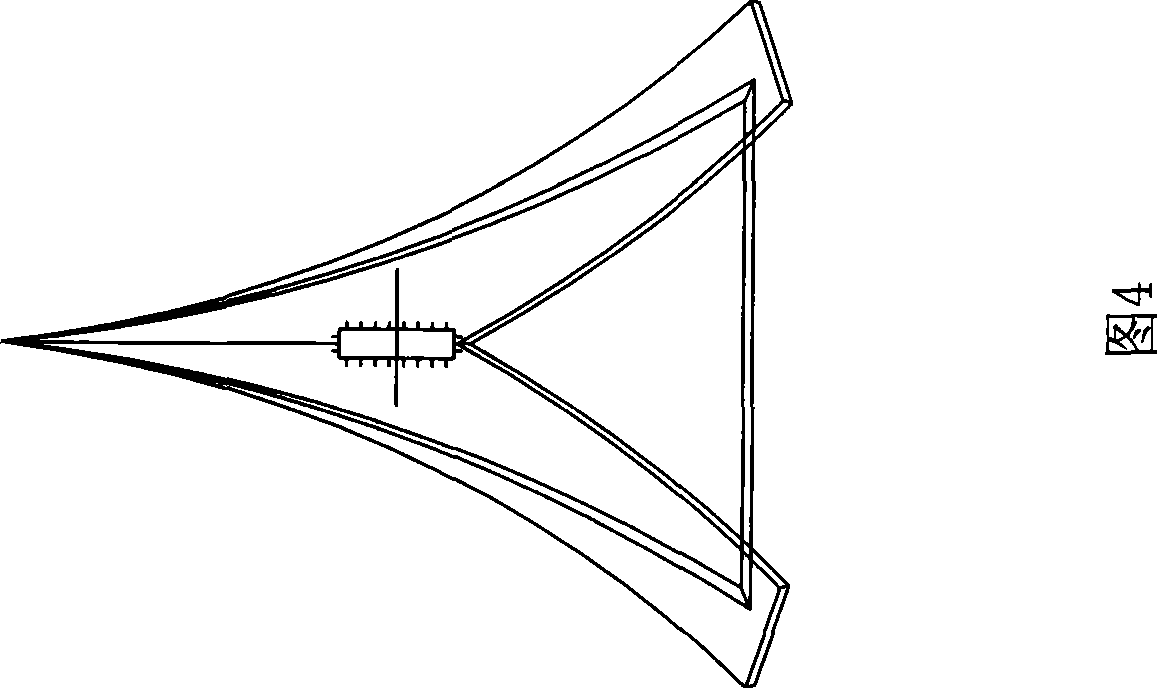

[0030] As shown in Figures 6 to 7, the structure of this embodiment is basically the same as that of Embodiment 1, except that oval-shaped heads 27 are installed at both ends of the reactor body of the reaction vessel, and the oval-shaped heads 27 are used to seal the kettle body 3 . A plurality of flying knife assemblies are arranged on the inner cylinder arm of the kettle body 3, and the flying knife assembly is composed of a flying knife base 10, a drive motor 23 and a flying knife blade 24, and the driving motor 23 and the flying knife blades are installed on the flying knife base 10. Blade 24. The flying knife assembly is used to crush and shear the agglomerated materials and long fibers, so that the materials are mixed uniformly, which is more in line with the requirements of the production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com