Rolling device and method

A technology of rolling and driving devices, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low production efficiency and increased production cost, and achieve the effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The spheronizing device and spheronizing method of the present technical solution will be described in detail below in conjunction with the embodiments.

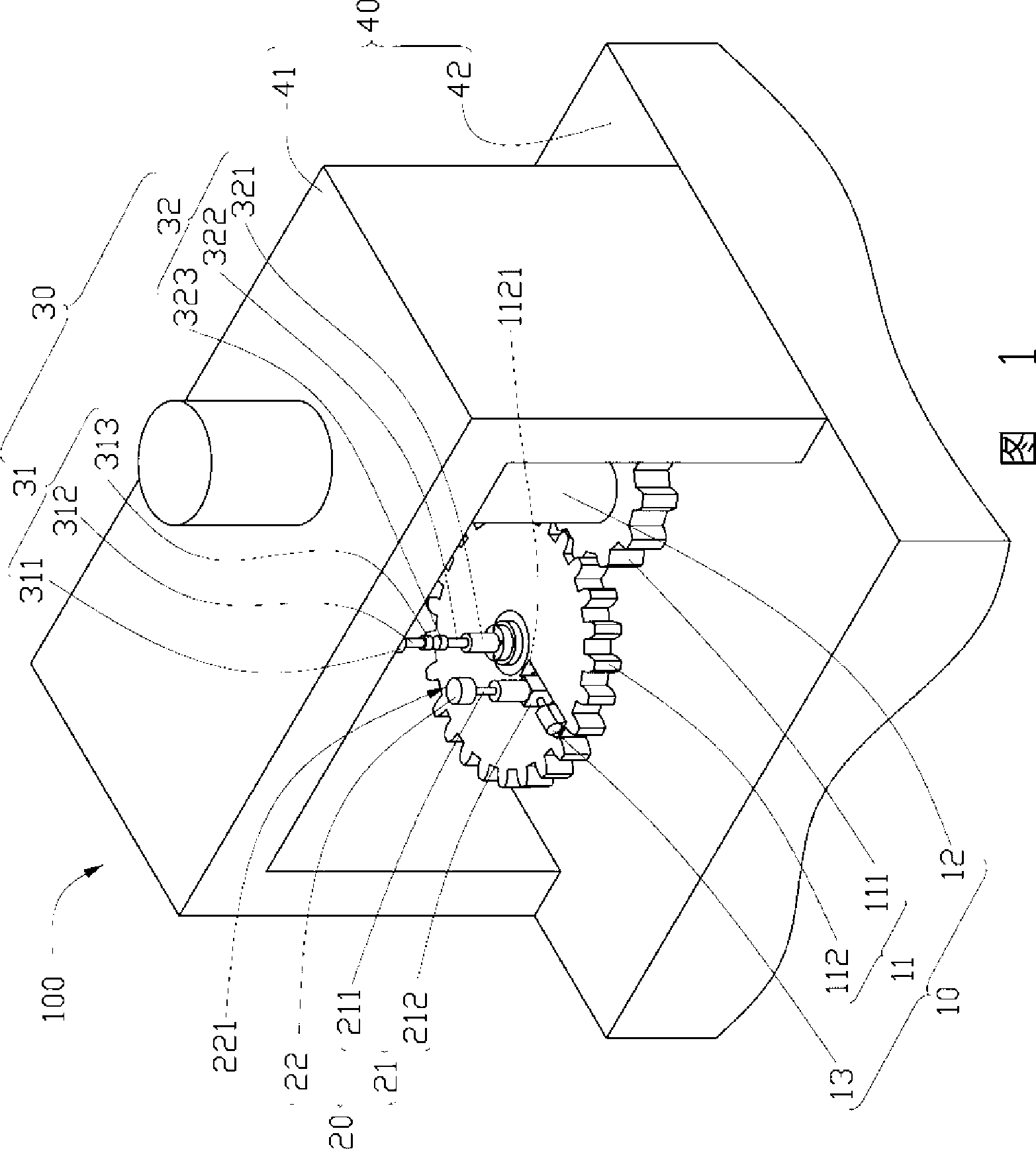

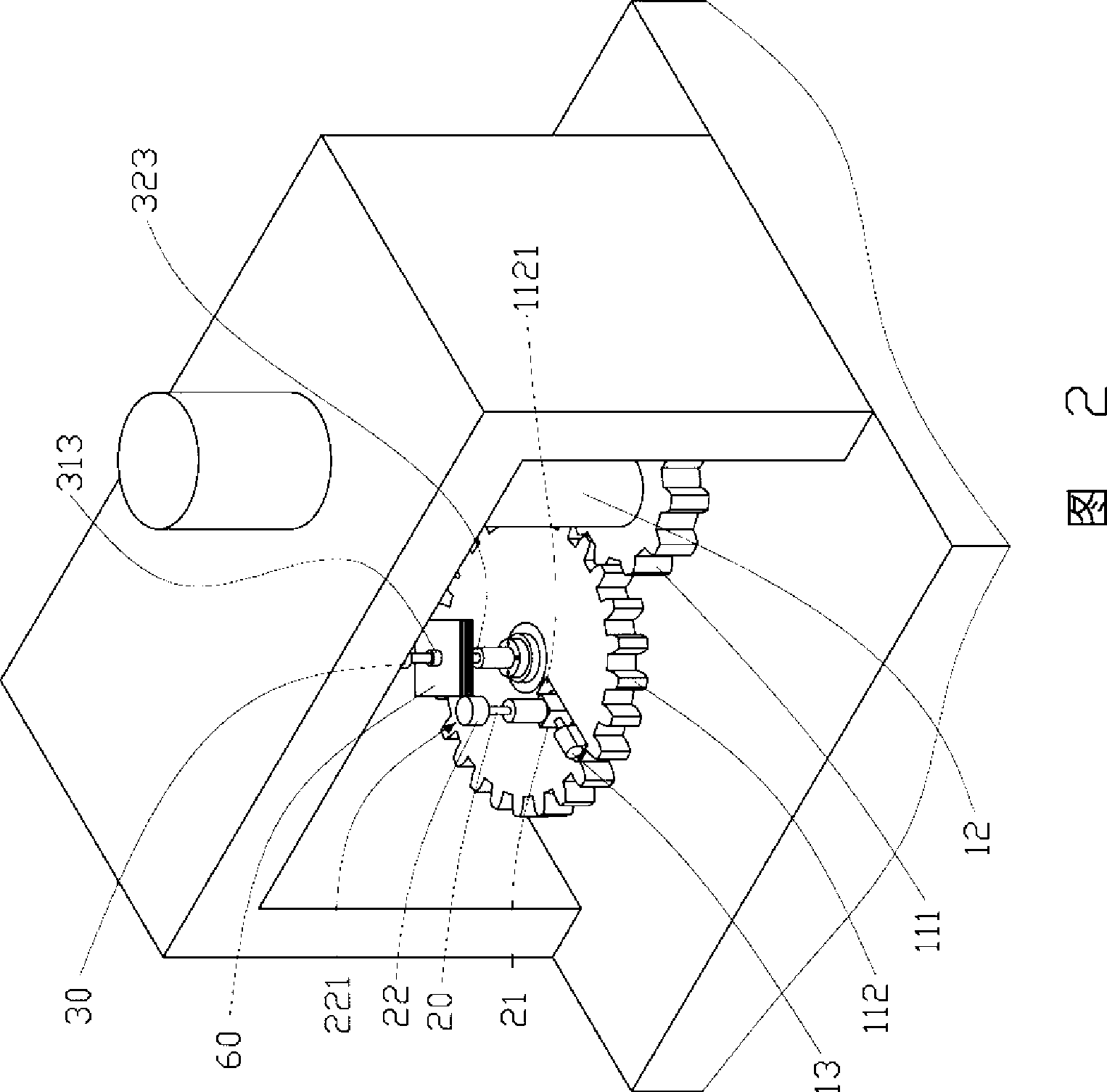

[0017] Referring to FIG. 1 , it is a schematic diagram of a rounding device 100 provided by the first embodiment of the technical solution. The rounding device 100 includes a driving device 10 , a rounding component 20 , a clamp 30 and a machine table 40 .

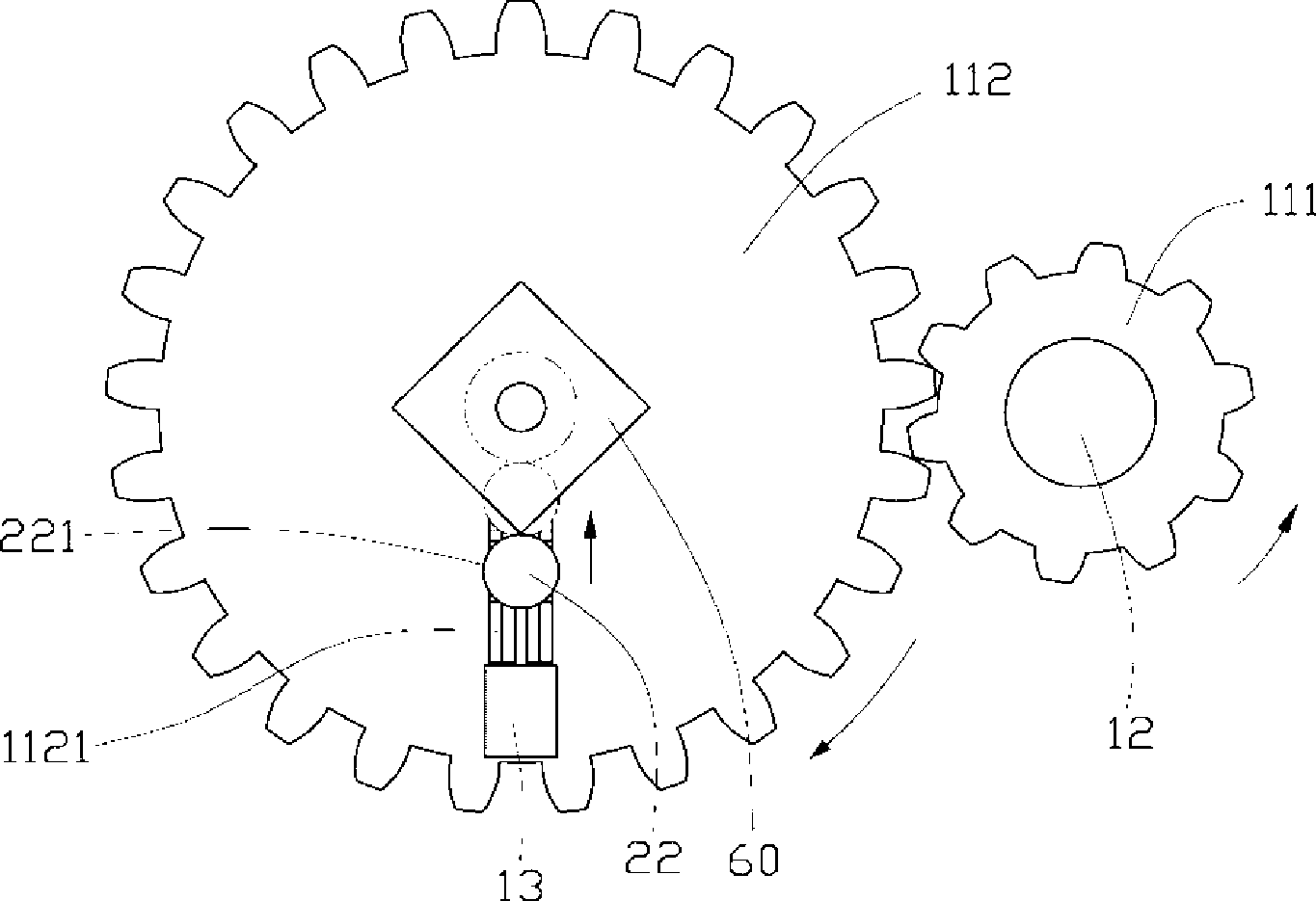

[0018] The driving device 10 includes a transmission device 11 , a first driver 12 and a second driver 13 . The driving device 10 is used to adjust the distance between the rounding part 20 and the workpiece to be rounded, and to drive the rounding part 20 to rotate on its own and around the workpiece to be rounded.

[0019] The transmission 11 includes a pair of meshing gears, namely a first gear 111 and a second gear 112 . The first gear 111 is connected with the first driver 12 , it can run under the action of the first driver 12 and drive the second gear 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com