Ground processing system and method for contacting joint of ground processing equipment and charging stand

A processing device and processing system technology, applied in the direction of position/direction control, control/regulation system, secondary battery charging/discharging, etc., can solve the problems of consumption, long time, etc., and achieve prolonged cleaning time, accurate and fast docking, The effect of product modeling and mold opening convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

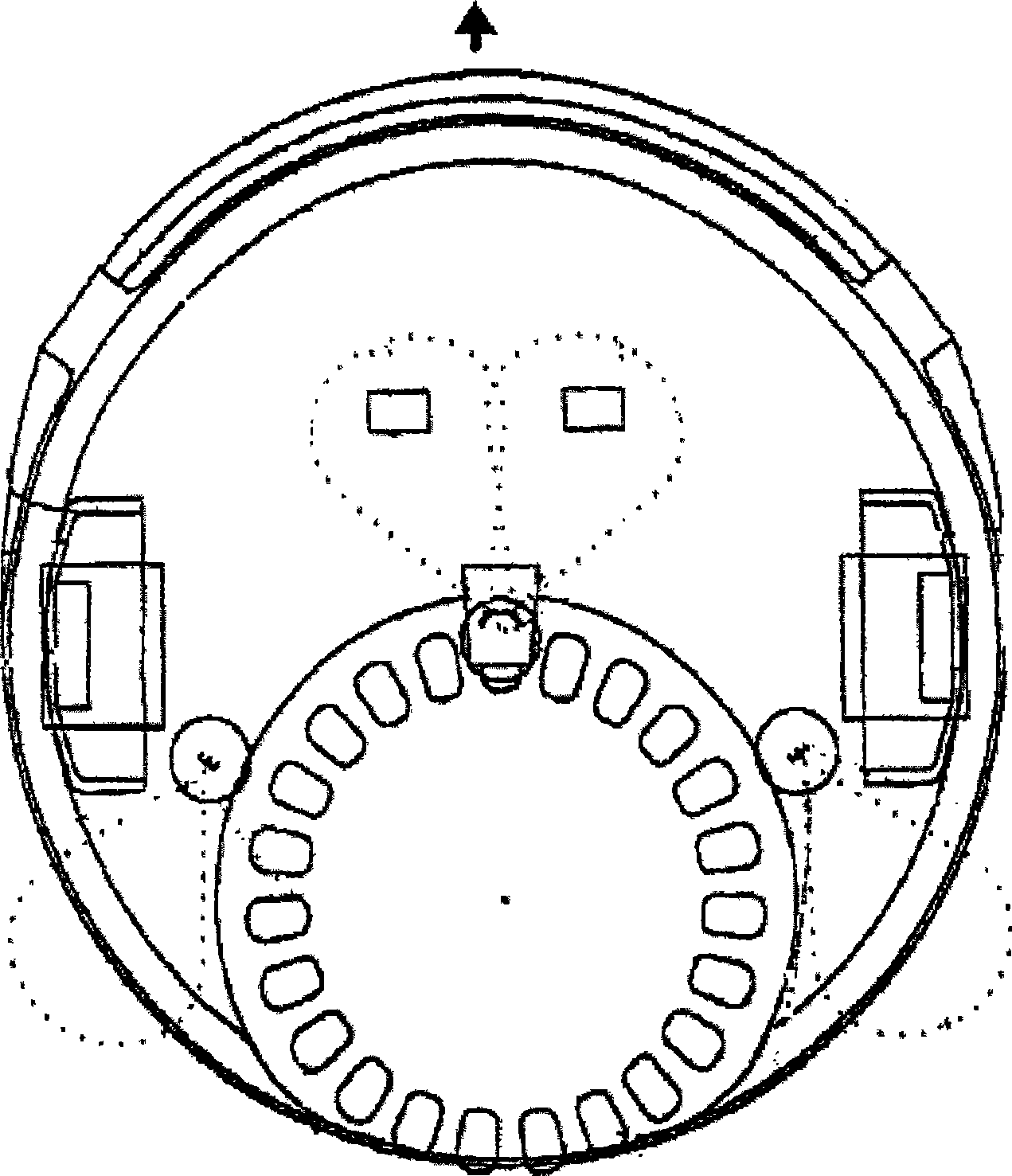

[0034] image 3 It is a structural schematic diagram of the ground treatment system of the present invention, such as image 3 As shown, the present invention provides a ground treatment system 1 , which includes a ground treatment device 10 and a charging stand 20 .

[0035] The ground processing device 10 includes a mechanism unit 101, a rechargeable energy supply unit (not shown in the figure) and a control unit (not shown in the figure). The mechanism unit 101 includes a housing 102, and an energy supply unit and a control unit (not shown in the figure) are arranged inside the housing 102 . The mechanism unit 101 also includes a traveling mechanism. Two driving wheels 103 are respectively located on both sides of the ground processing device 10 and below the ground processing device 10 . Each driving wheel 103 is respectively equipped with an electric motor (not shown in the figure) to drive. The electric motor is arranged inside the casing 102, and the energy is supplie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com