Top clamp type side shielding apparatus for electroplating printed circuit board

A technology for printed circuit boards and shielding devices, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of material, labor and power waste, increasing the thickness deviation of plating settings, and wasting copper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is described further in conjunction with accompanying drawing now:

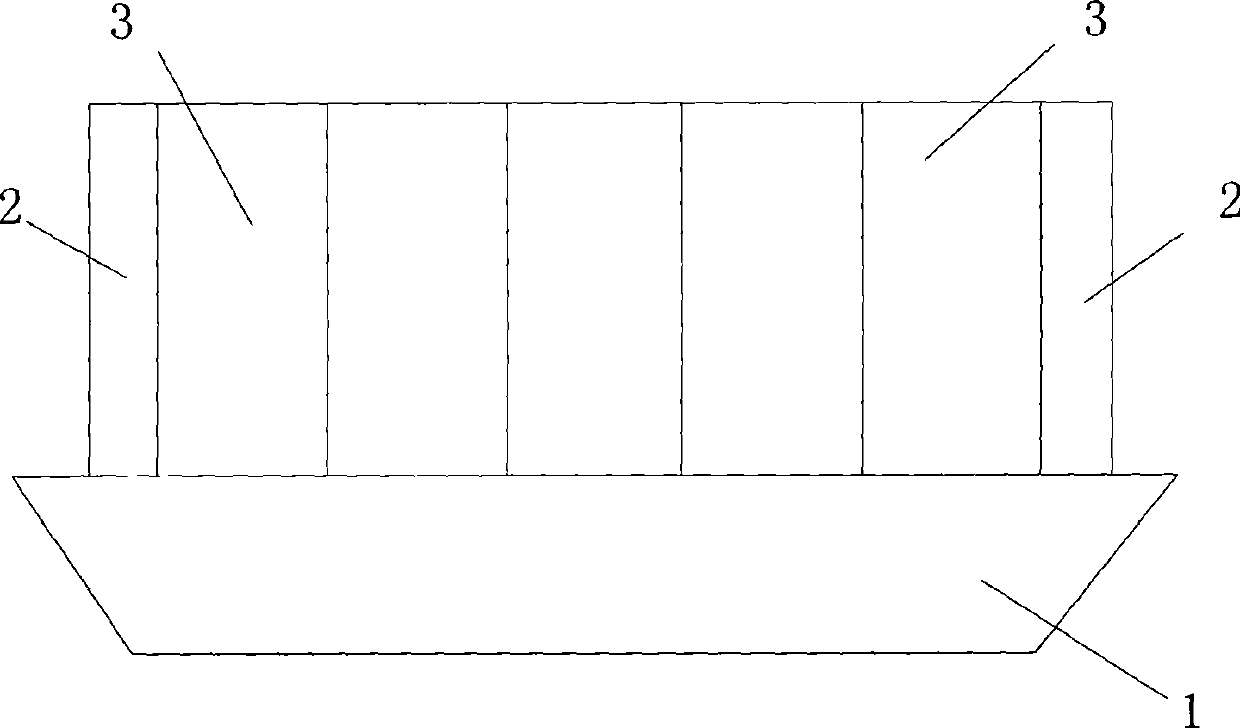

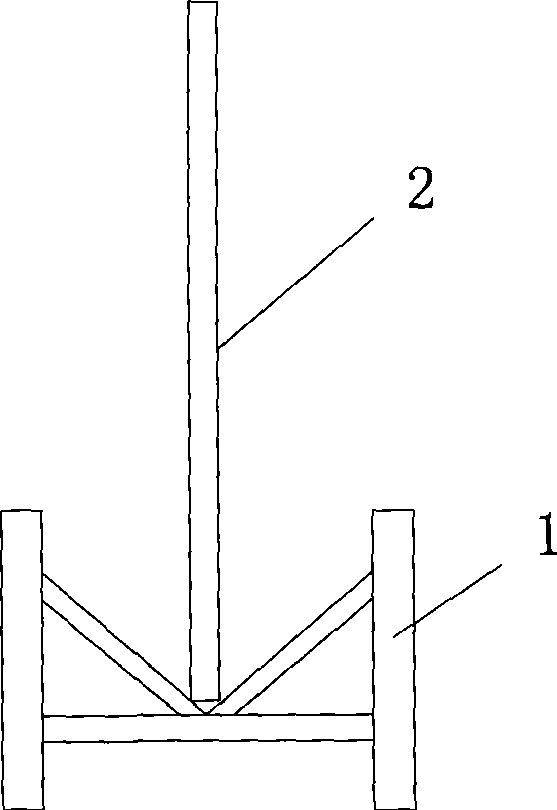

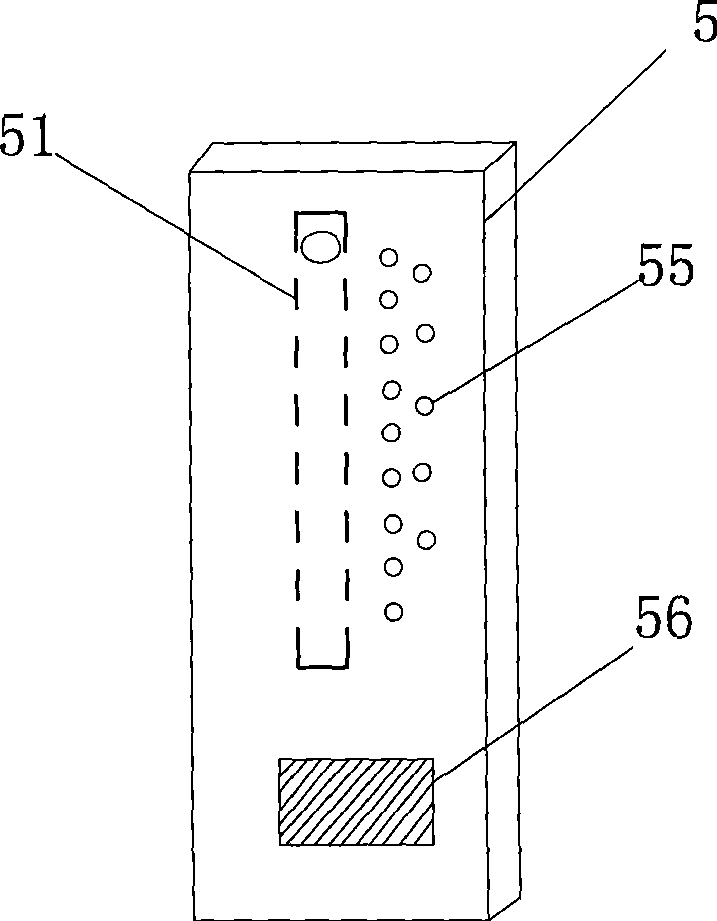

[0022] Figure 4 It is the schematic diagram when the boat-shaped baffle of the present invention floats on the liquid surface, and the boat-shaped baffle 1 floats on the liquid surface 41 of the electroplating solution 4, and now the connecting rod 52 is outwardly opened, and the connecting rod 52 is in an approximately horizontal state; A pair of side baffles 5 are respectively provided at both ends of the ship-shaped baffle 1, and a longitudinal chute 51 is provided on the side baffle 5, and the side baffles 5 are connected with the boat-shaped baffle 1 through a connecting rod 52, and the connecting rod 52 One end is fixedly connected to the boat-shaped baffle 1 through a fixed shaft 53 , and the other end of the connecting rod 52 is movably connected to the chute 51 through a movable shaft 54 . Such as image 3 As shown, the side baffle 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com