Steel rail mounting system

A technology of rails and installation points, applied in the direction of tracks, fixed rails, roads, etc., can solve the problems of complex assembly and maintenance work, and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

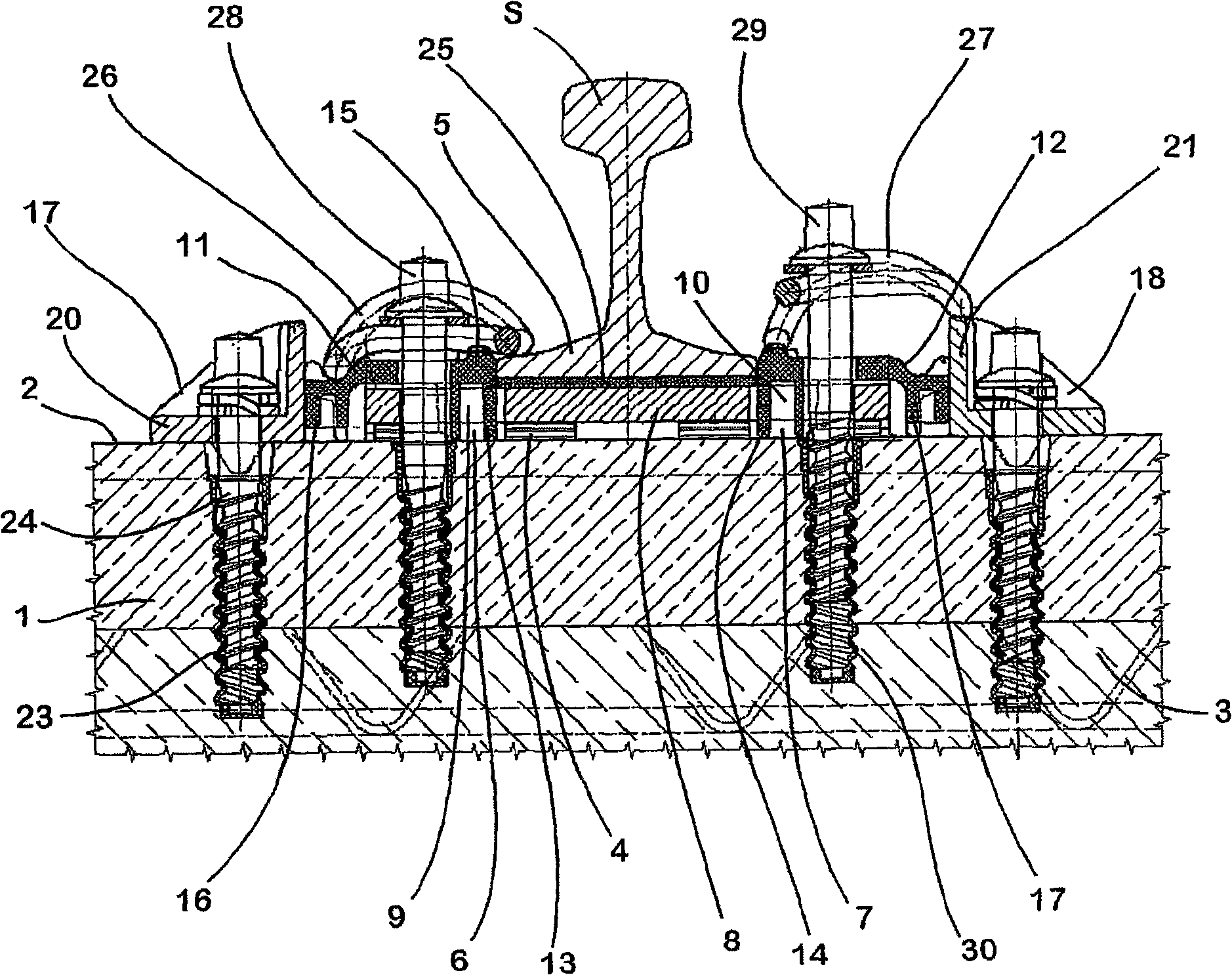

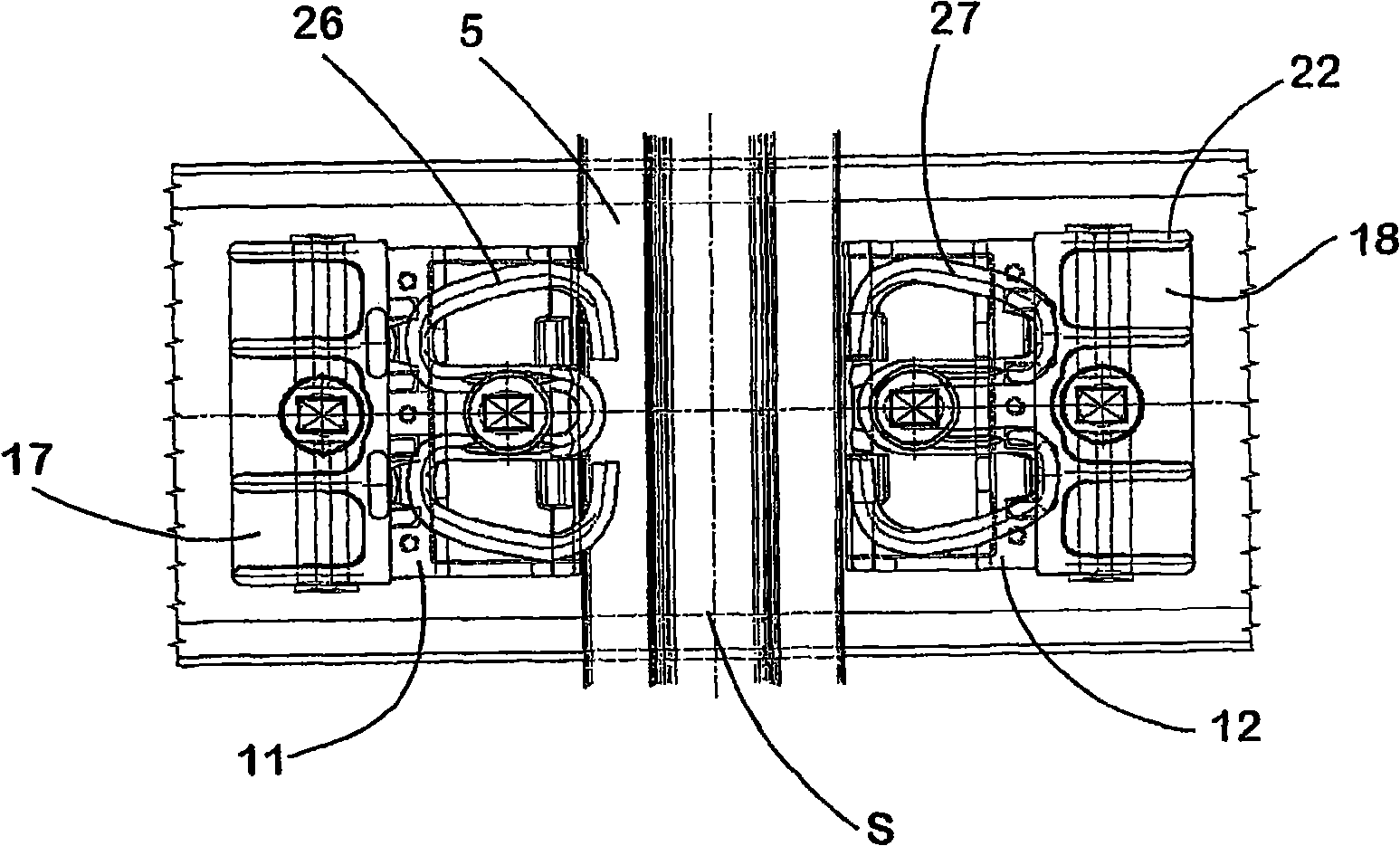

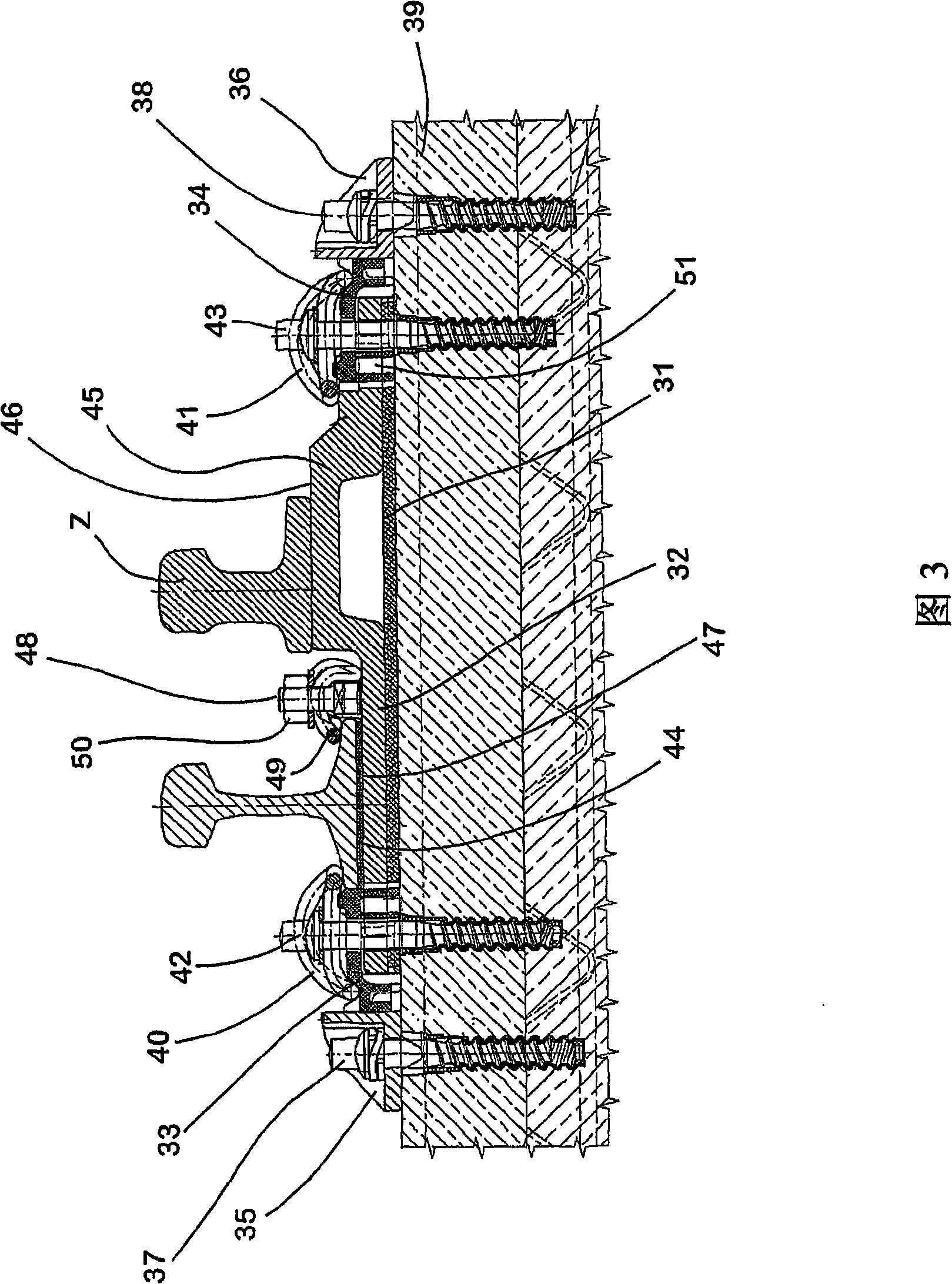

[0022] exist figure 1 In the rail installation shown, the rail S is a conventional straight rail mounted on a concrete sleeper 1 having a flat upper side 2 and resting on a base plate 3 also made of concrete. In order to fix the sleepers 1 on the base plate 3 , filling concrete (not shown) can be poured into the gap between two adjacent sleepers 1 . The mounting system for mounting the rail S to the sleeper 1 includes the components described below.

[0023] An elastic intermediate layer 4 is applied to the flat upper side 2 of the concrete sleeper 1 and, viewed from the transverse direction, to the longitudinally extending steel rail S, on the basis of which the elastic intermediate layer 4 is positioned centrally. The width B of the elastic intermediate layer 4 is greater than the width of the rail base 5 of the rail S, so that the intermediate layer 4 protrudes beyond the rail base 5 on both sides. The intermediate layer 4 has corresponding openings 6 , 7 in the region pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com