Liquid cooling permanent magnet speed inhibitor capable of stage division

A retarder and graded technology, applied in the field of gradeable liquid-cooled permanent magnet retarders, can solve the problems of increased rotor drum temperature, poor heat dissipation effect, low working reliability, etc., and achieves small volume and mass, overall Compact structure, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

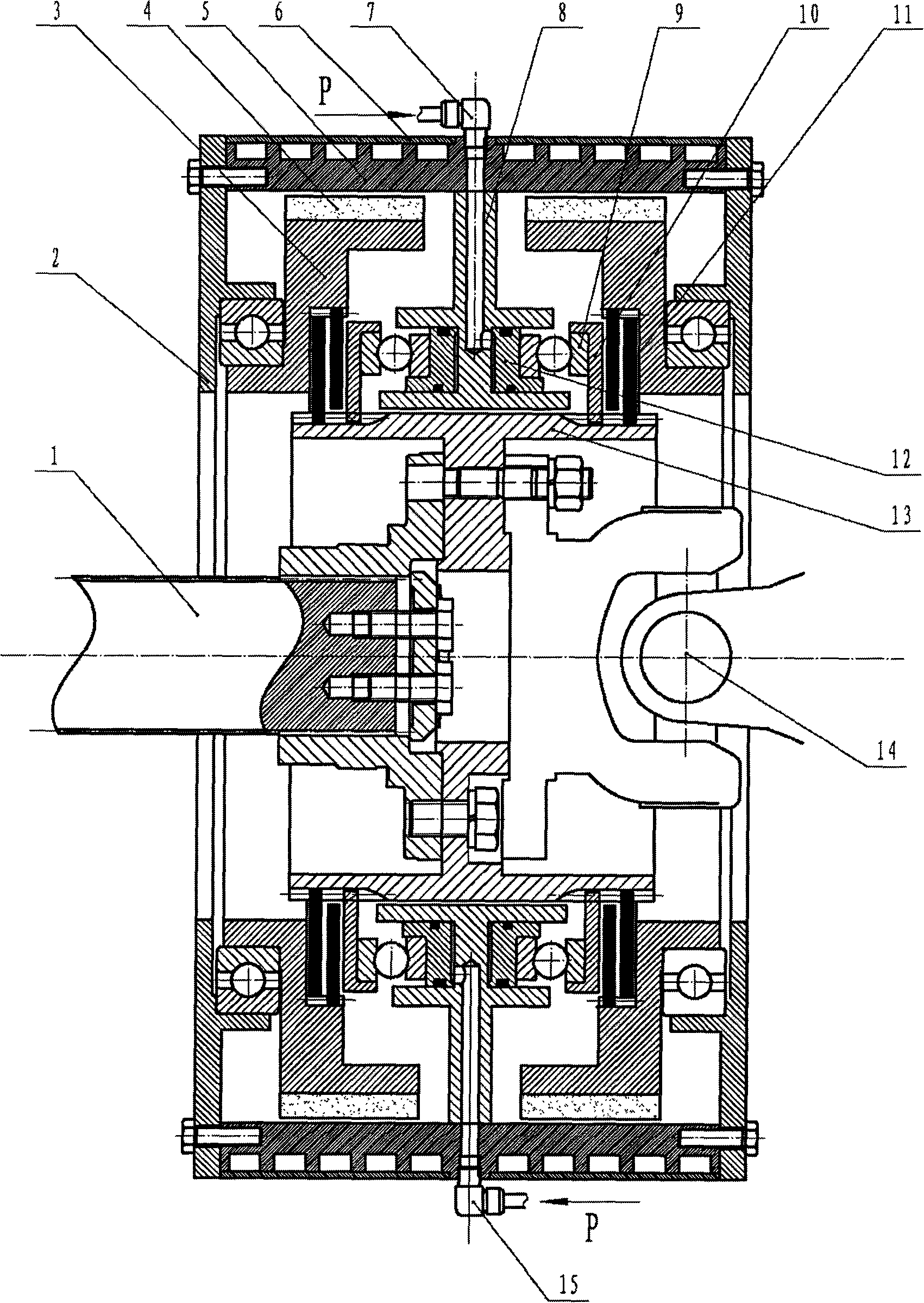

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] The specific structure of this embodiment is as figure 1 As shown, it includes a stator, a rotor, a control mechanism, a transmission output shaft 1 and a transition flange 13 fixedly connected to the transmission output shaft. The transition flange 13 is connected to the transmission shaft by bolts to provide a power source for the retarder.

[0015] The stator includes two bearing end caps 2 and a circular stator drum 5. The two bearing end caps 2 are respectively fixed on the two ends of the stator drum 5, forming a space with the stator drum 5, and the rotor and the control mechanism are placed in the space. inside the space. The bearing end cover 2 is fixedly connected with the stator drum 5 through bolts, and a channel for cooling water flow is provided on the outer surface of the stator drum 5 , and the channel is sealed by a water-cooling sealing cover 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com