Water treatment process and equipment

A technology of water treatment equipment and auxiliary processor, which is applied in the fields of magnetic field/electric field water/sewage treatment, etc., and can solve problems such as greatly different chemical and physical properties, unsatisfactory treatment effect, and poor treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

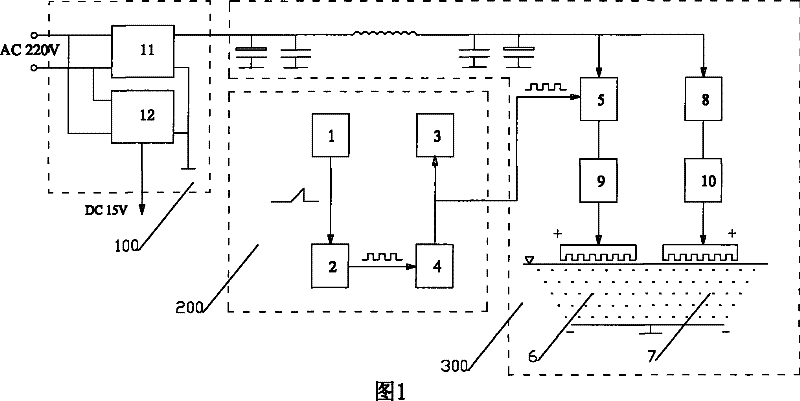

[0025] figure 1 It is a block diagram of the circuit principle of the water treatment equipment of the present invention. Such as figure 1 As shown: the circuit of the water treatment equipment involved in the present invention is composed of a power supply 100 , a control signal generator 200 and a main circuit 300 .

[0026] The power supply 100 is composed of a DC constant current source 11, a DC15V power supply 12 and the like.

[0027] The control signal generator 200 is composed of a frequency sweep signal generator 1 , a frequency sweep pulse generator 2 , a control signal working instruction 3 and a pulse amplifier 4 .

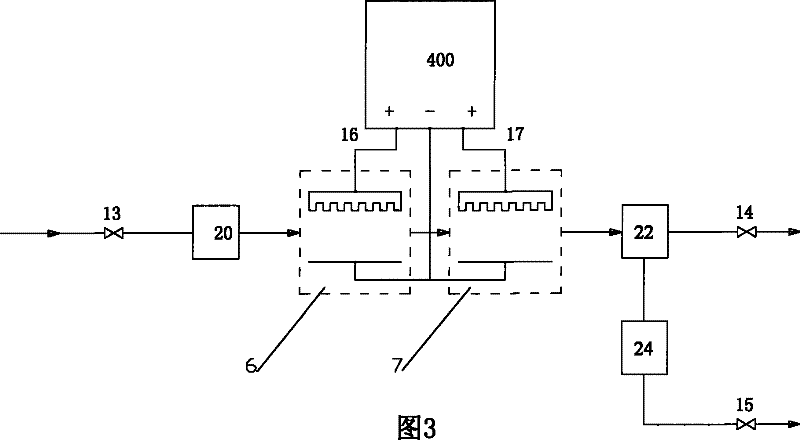

[0028] The main circuit 300 includes a switch circuit 5 , a main processor 6 , a deionization auxiliary processor 7 , and a blowdown control circuit 8 .

[0029] The working process of the water equipment is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com