Cast die tool of multi-bottom pan and technique for producing multi-bottom pan using the die

A technology of die-casting mold and double bottom pot is applied in the field of casting, which can solve the problems of low production efficiency, complicated manufacturing process, and bottoming out, etc., and achieve the effects of improving production efficiency, wide application range and flexible positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

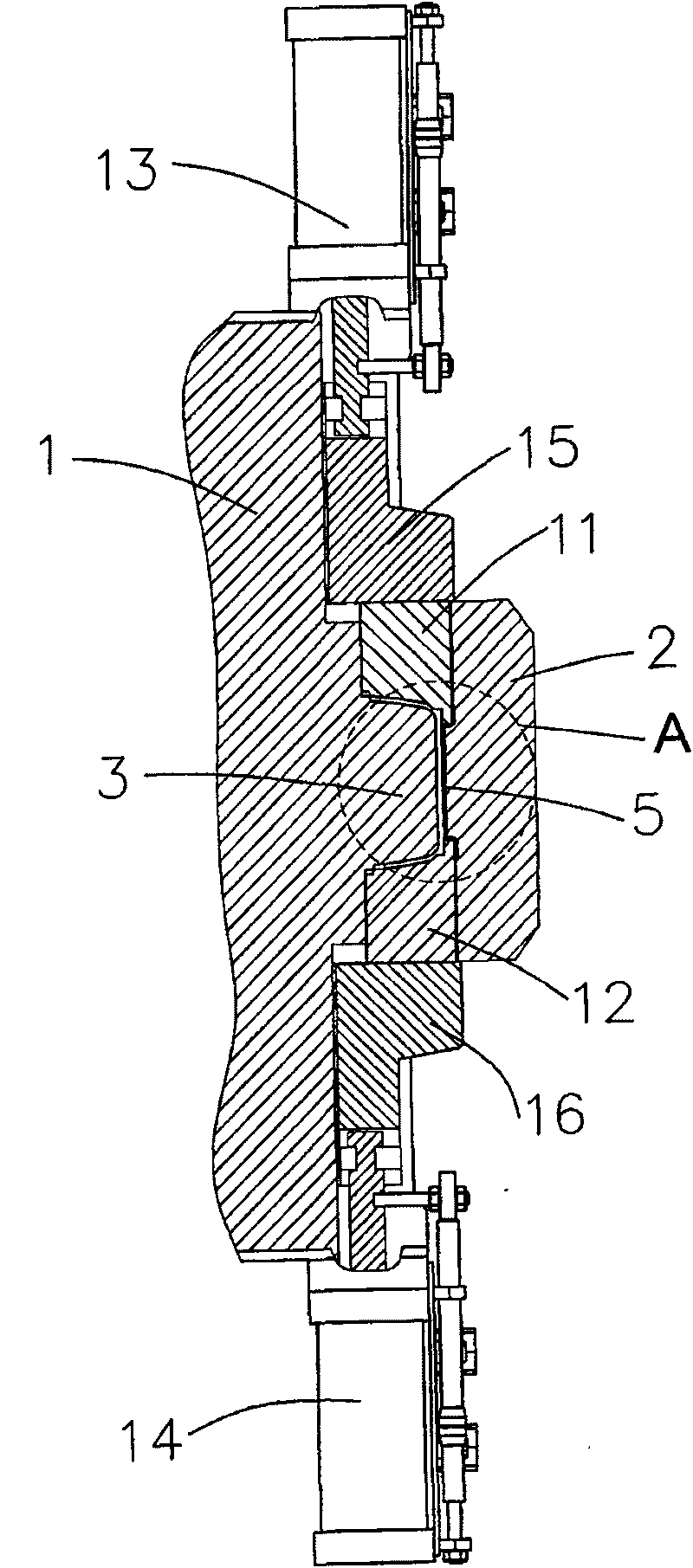

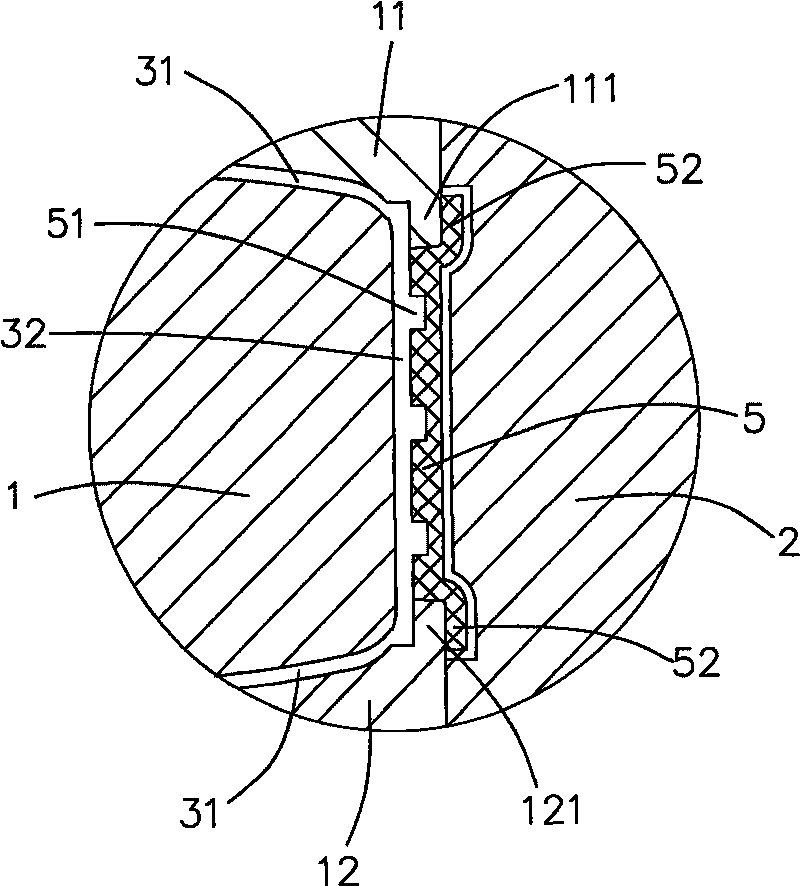

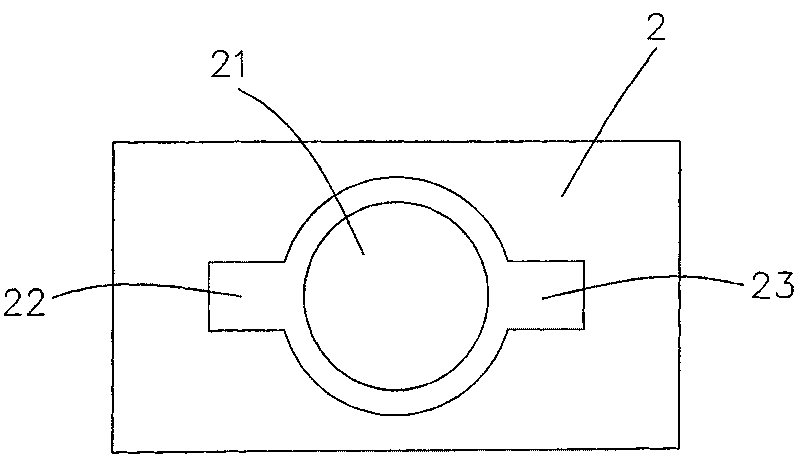

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , according to the die-casting mold of a kind of compound bottom pot that the present invention provides, comprise fixed mold 1 and movable mold 2, fixed mold 1 inner surface is provided with pot body model 3 and aluminum liquid injection port 4, and pot body model 3 two sides have Positioning seat 11,12, two positioning seats 11,12 are respectively fixed on the sliding seat 15,16, and sliding seat 15,16 is connected with the piston rod of the cylinder 13,14 of its outside respectively, like this, positioning seat 11,12 just It can slide in and out according to the reciprocating motion of cylinders 13 and 14, thereby adjusting the distance between the positioning seat and the pot body model. At the same time, when the positioning seat is damaged, it can also be disassembled and replaced separately to reduce maintenance. cost. The inner surfaces of the two positioning seats 11, 12 correspond to the shape of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com