Automatic control system of glue-extracting working procedure in gelatine production course

A technology of automatic control and production process, applied in electrical program control, preparation of animal glue or gelatin, comprehensive factory control, etc. Efficiency, the monitoring of production equipment cannot be guaranteed, etc., to achieve the effect of improving the quality of gelatin products, ensuring continuity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

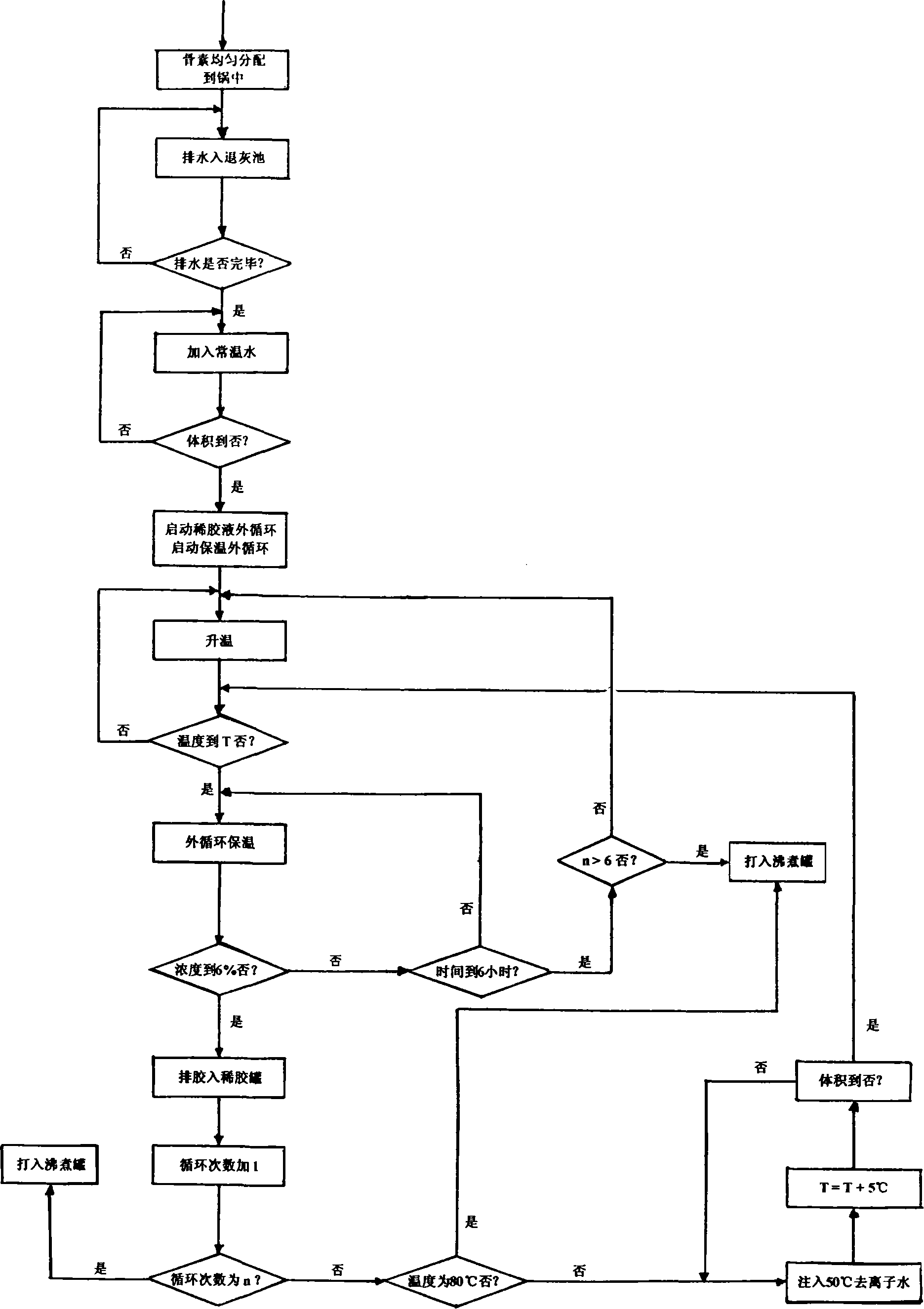

Method used

Image

Examples

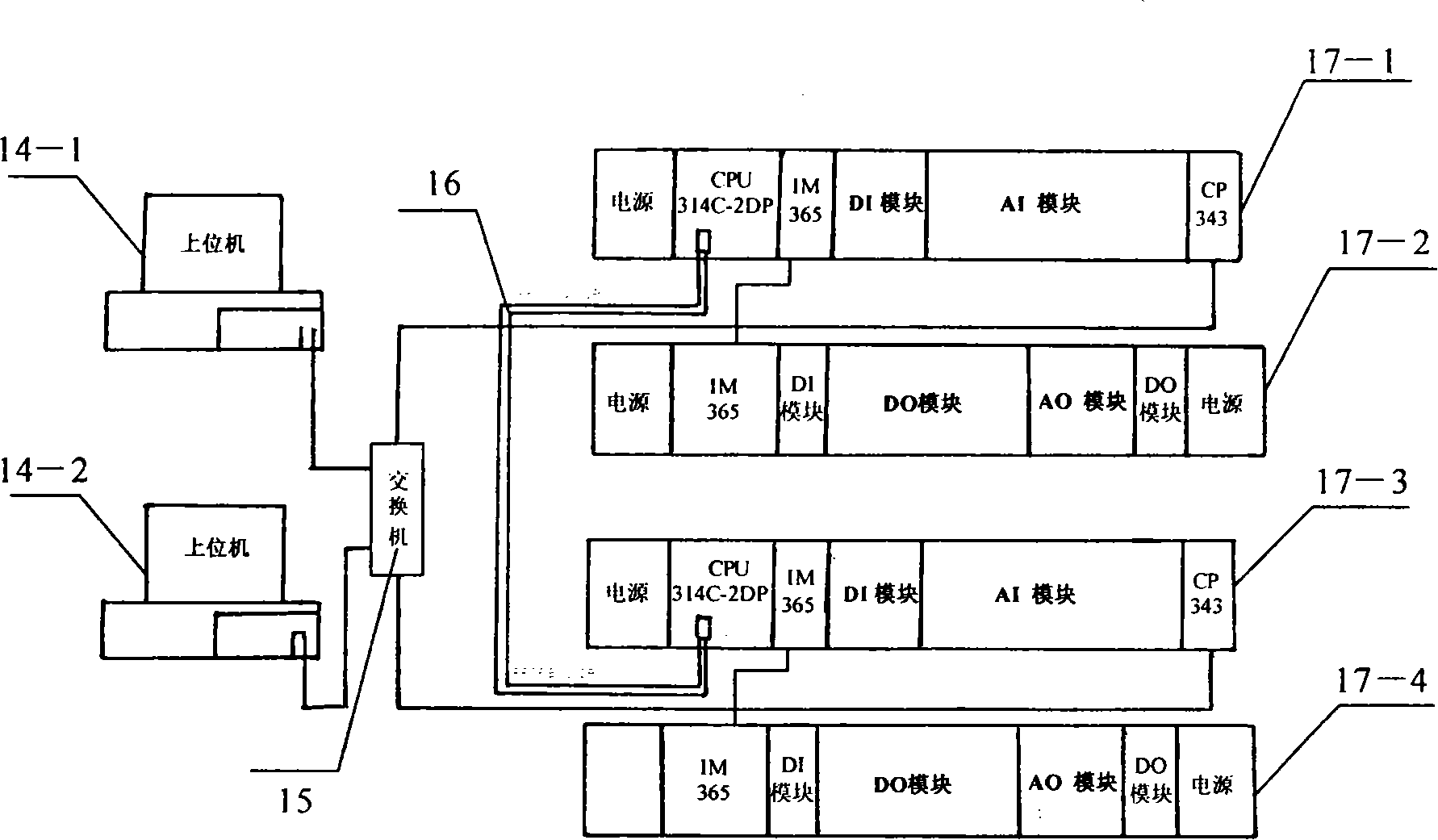

Embodiment Construction

[0011] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

[0012] As shown in Figure 1, in the described gelatin production process, the automatic control system of the glue-lifting process includes a glue-lifting pot 12 containing a thermal insulation interlayer, and the bottom of the glue-lifting pot 12 is provided with a glue circulation pipeline, and the test of the glue-lifting pot 12 A radio frequency admittance liquid level gauge 9 is provided in the well, a first temperature sensor 8-1 and a liquid level switch 10-1 are arranged in the insulation interlayer of the rubber lifting pot 12, and a second The temperature sensor 8-2, the water intake cycle of the rubber lifting pot 12 and its insulation layer include normal temperature deionized water electric ball valve 1-1, 50°C deionized water electric ball valve 1-2, cleaning water electric ball valve 1-3 and disinfection water The electric ball valve 1-4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com