Dip laneway digging hole layout mode

A roadway and blasthole technology, which is applied in the field of drilling and blasting, can solve the problems that the rock blocks cannot be effectively thrown away after the blasting, and the blasting efficiency of the downhill roadway is low, so as to achieve the effect of speeding up the cycle footage, improving the blasting efficiency, and increasing the tunneling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

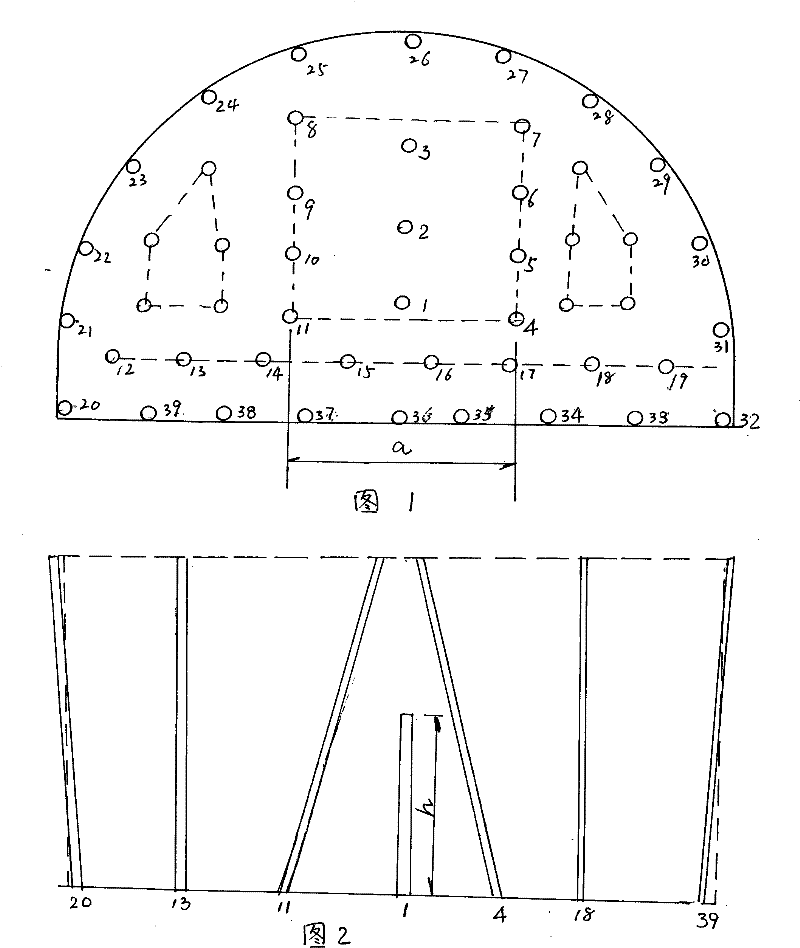

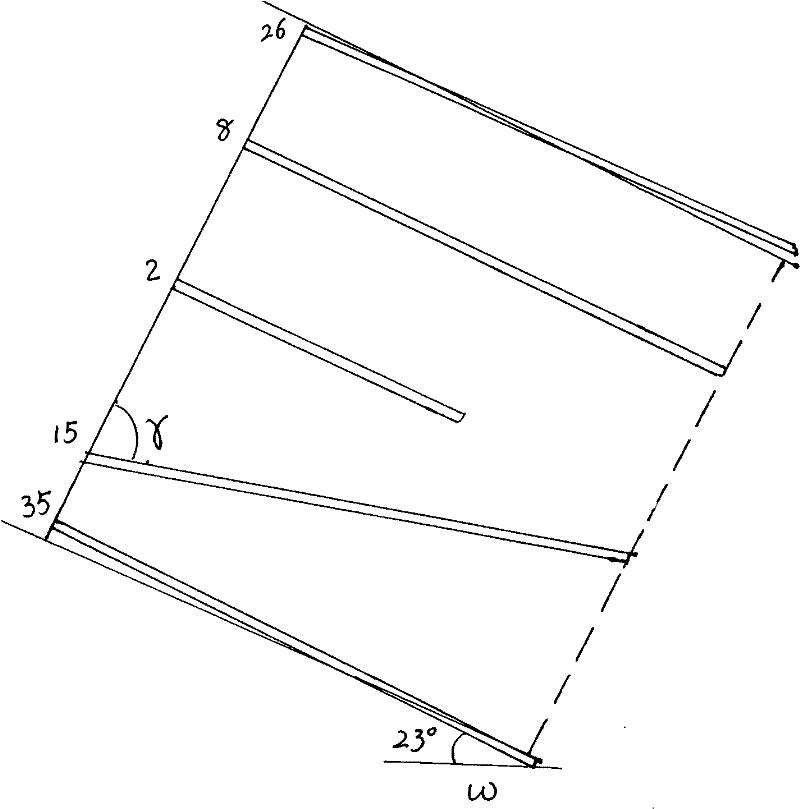

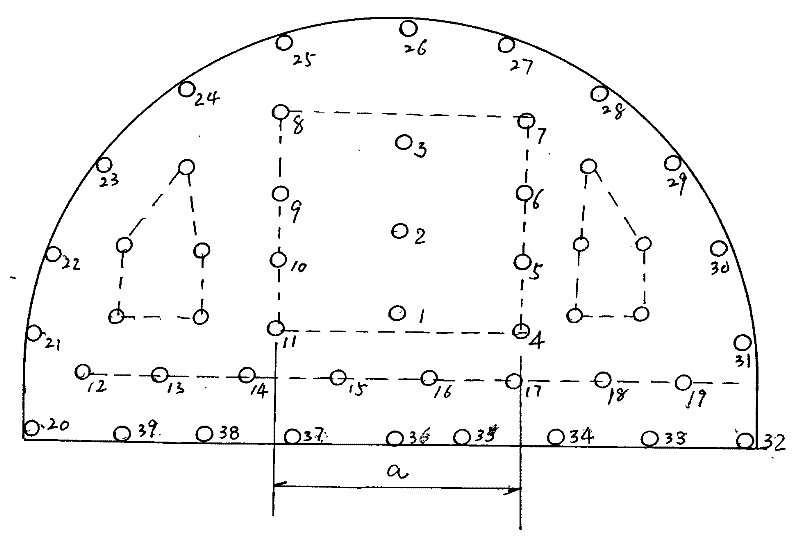

[0009] The embodiment is a downhill roadway with an inclination W=23°. The layout of excavation blastholes is as follows: Figure 1-Figure 3 shown. From figure 1 It can be seen that it has a total of 49 blastholes, of which No. 1-3 are auxiliary straight holes for cutting, and the eye depth h=0.8-1.0 meters; No. 4-7 and No. 8-11 are divided into two rows on the left and right. Wedge-shaped cutting holes are arranged in the middle and upper part of the roadway section, and the distance between two rows is a = 1.0-1.2 meters; No. 12-19 are auxiliary throwing holes, and the drilling direction and the section are at an angle of γ = 85° to drill obliquely upward; Nos. 20-32 are peripheral holes, which are evenly arranged on the two sides and the top contour of the section; No. 33-39 are bottom holes, which are evenly distributed on the bottom contour of the section; the rest of the unnumbered blastholes are auxiliary holes, which are evenly arranged On the space between the cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com