Device and method for manufacturing sausages

一种香肠、设备的技术,应用在制作香肠肠衣、香肠肠衣、香肠制作等方向,能够解决香肠肠衣不够坚固、压缩香肠串产生问题、香肠串破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

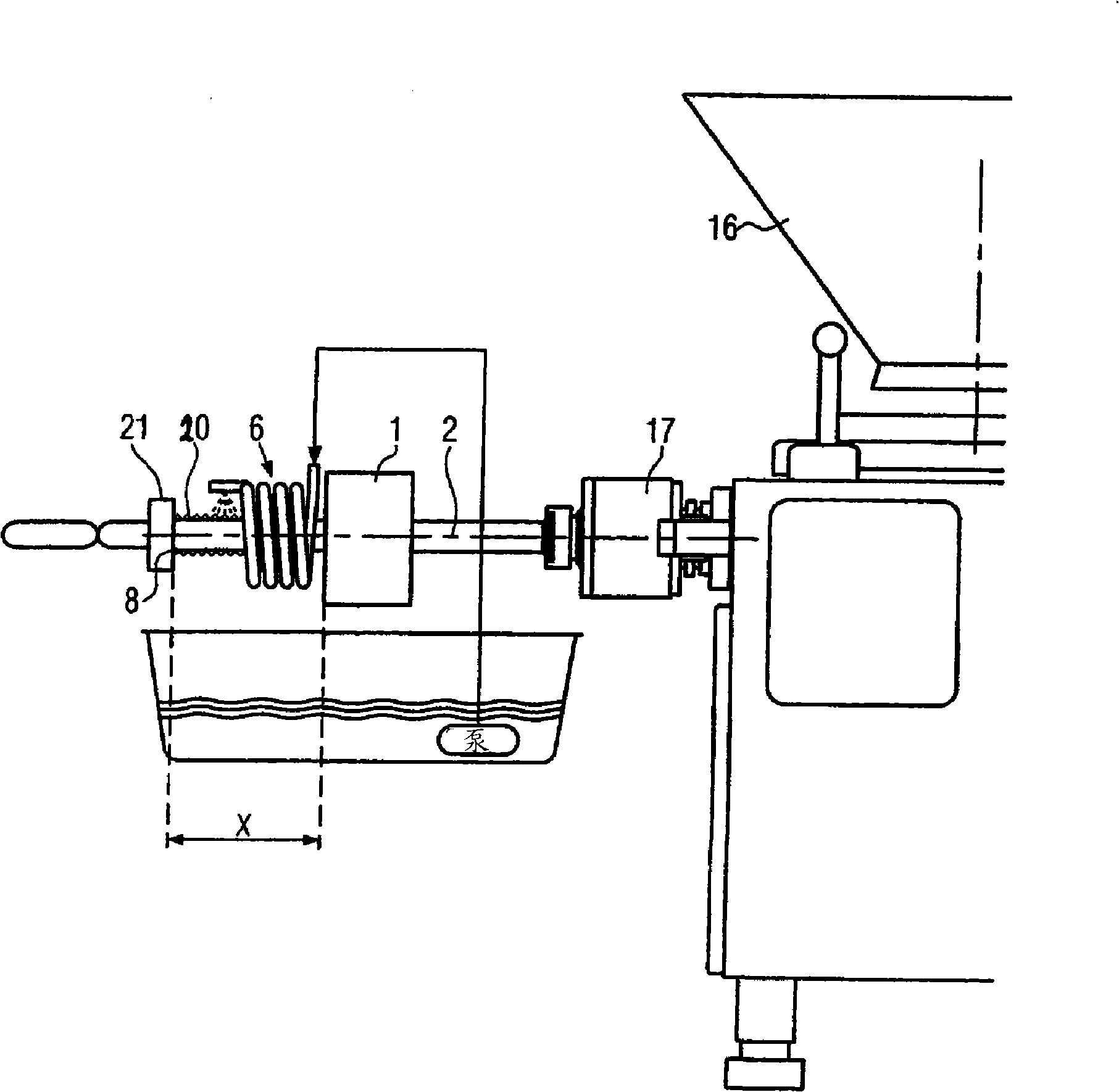

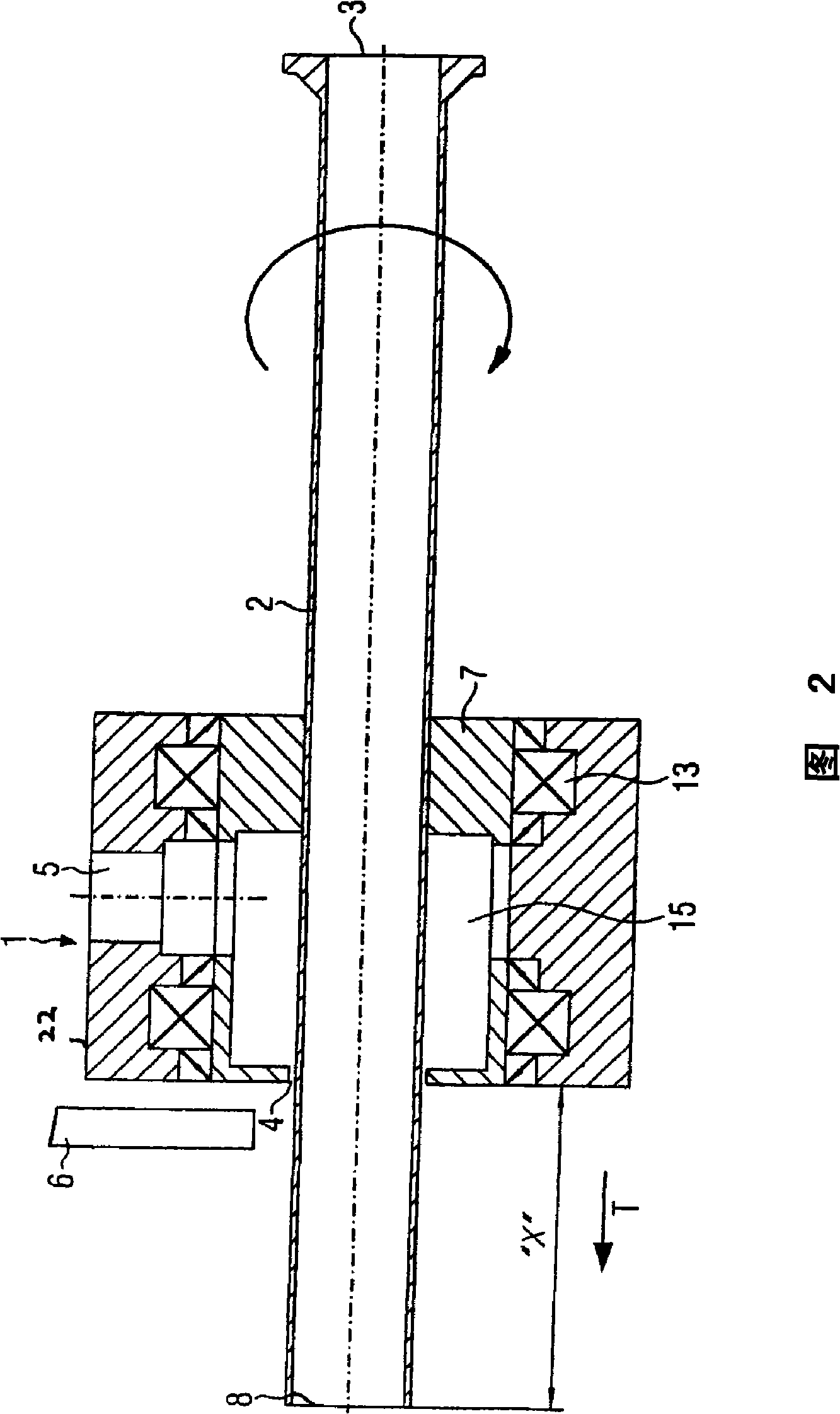

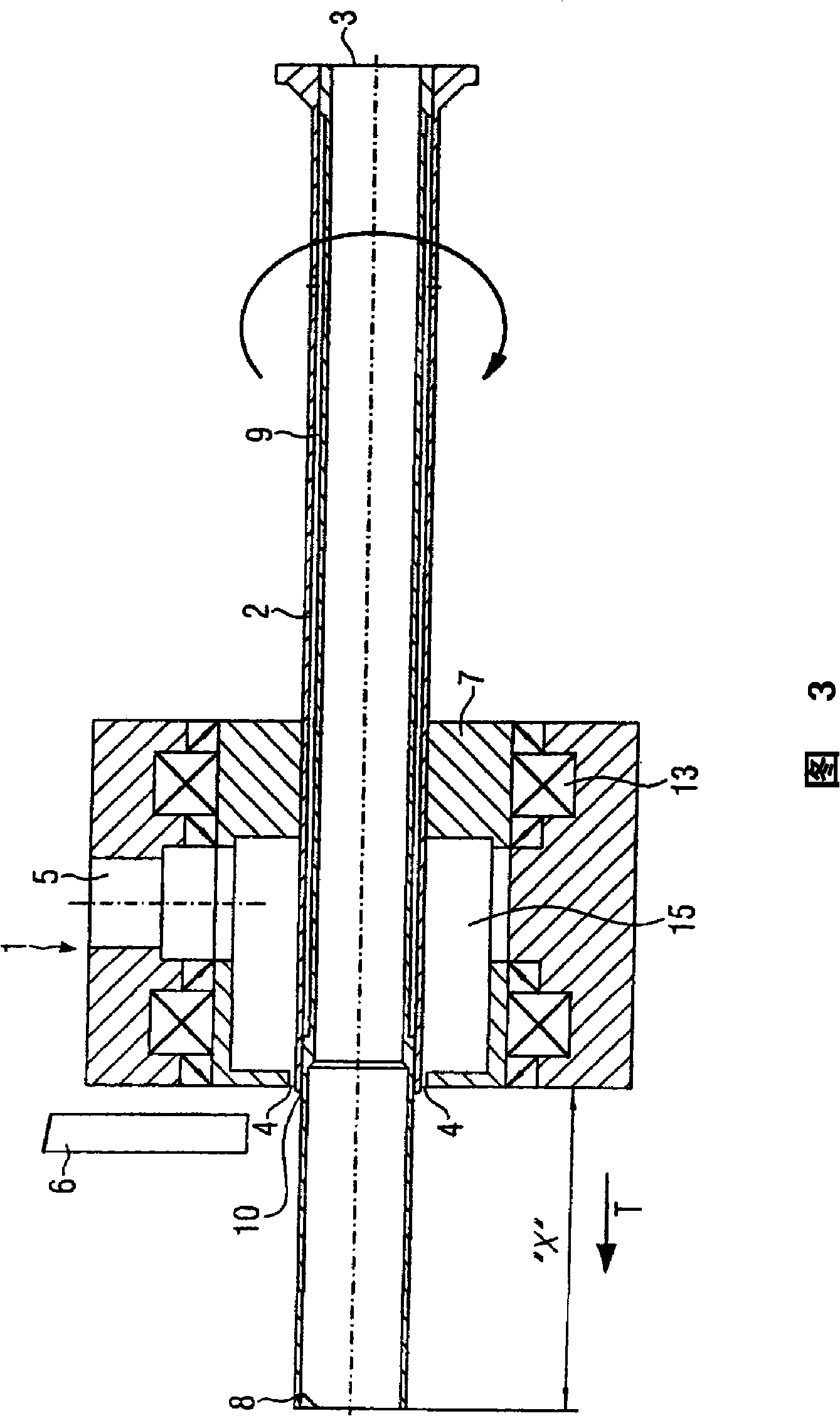

[0024] Such as figure 1 As shown, the charging machine comprises, in known manner, a hopper 16 through which pasty substances, such as sausage mince, are fed to a conveying mechanism located below the hopper. The conveying mechanism feeds the pressurized pasty substance into the charging pipe 2 so as to push the pasty substance into the sausage casing for sausage production. With the aid of the coextrusion head 1 it is also possible to produce sausage casings 20 for sausages. For curing the casing material, a device 6 is also provided for supplying a fixing solution for curing the ejected casing material. The device is here shaped as an annular injector through which the sausage casings to be cured are passed over the filling tube. The ring injector is connected to a supply of fixing solution supplied by a pump from another storage container for the ring injector.

[0025] Such as figure 1 As shown schematically, various devices 21 can be arranged immediately after the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com