Barrel type drilling tool

A drilling tool and barrel type technology, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of high hole forming efficiency, inability to obtain, and large drilling resistance, so as to make up for insufficient torque, improve efficiency, and make up for additional Effects of insufficient stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

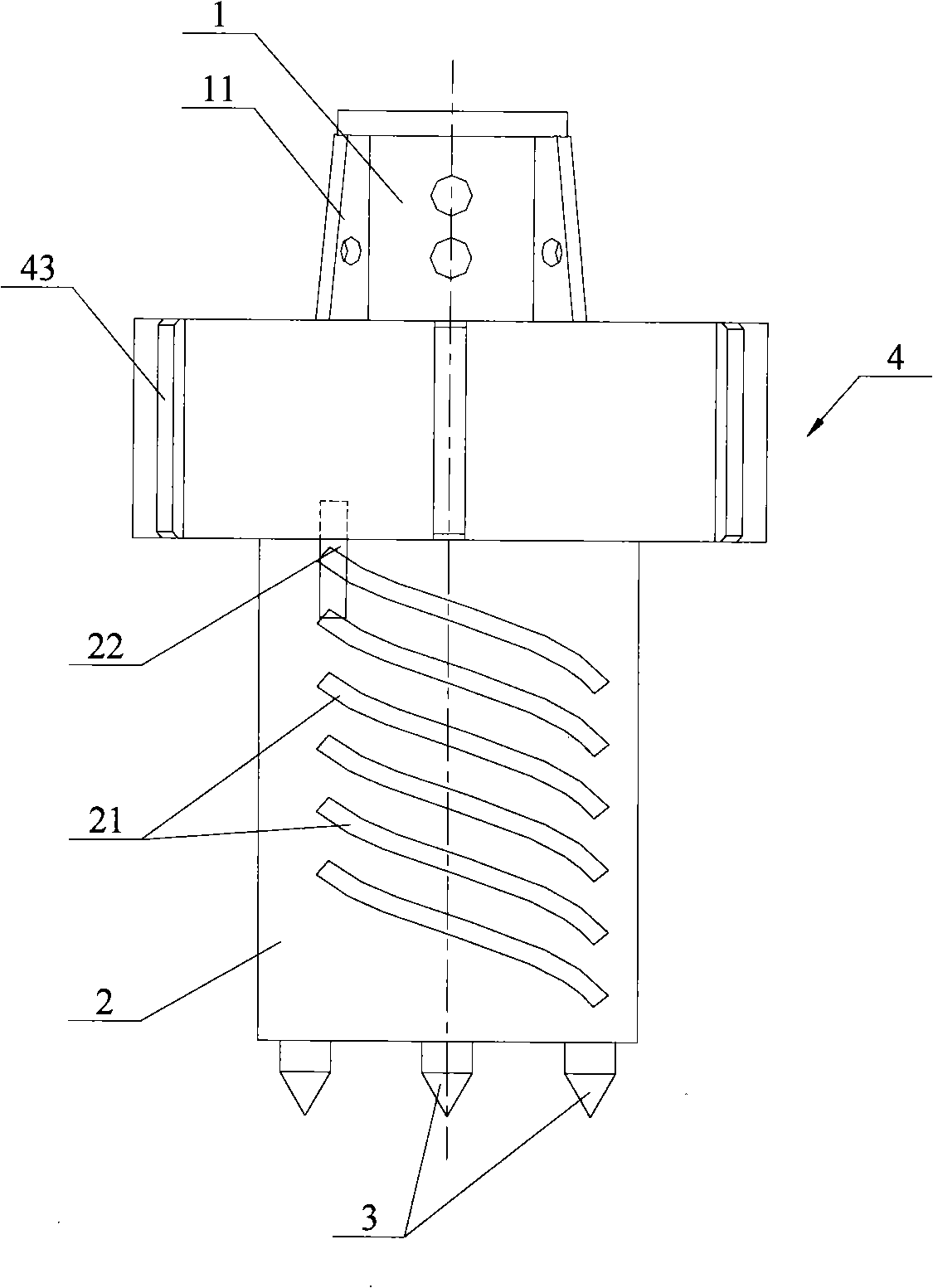

[0029] The core of the present invention is to provide a cylindrical drilling tool, which includes a connecting part, a cylindrical body and a cutting tool arranged in sequence from top to bottom; The outer diameter of the rotation is consistent with the diameter of the pile hole; during the rotation of the drilling tool, the outer wall of the centralizing part is offset against the wall of the pile hole to guide the drilling of the small hole. In this way, the diameter of the cylinder can be designed to be smaller, and then Greatly reduce drilling resistance and improve hole forming efficiency.

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings.

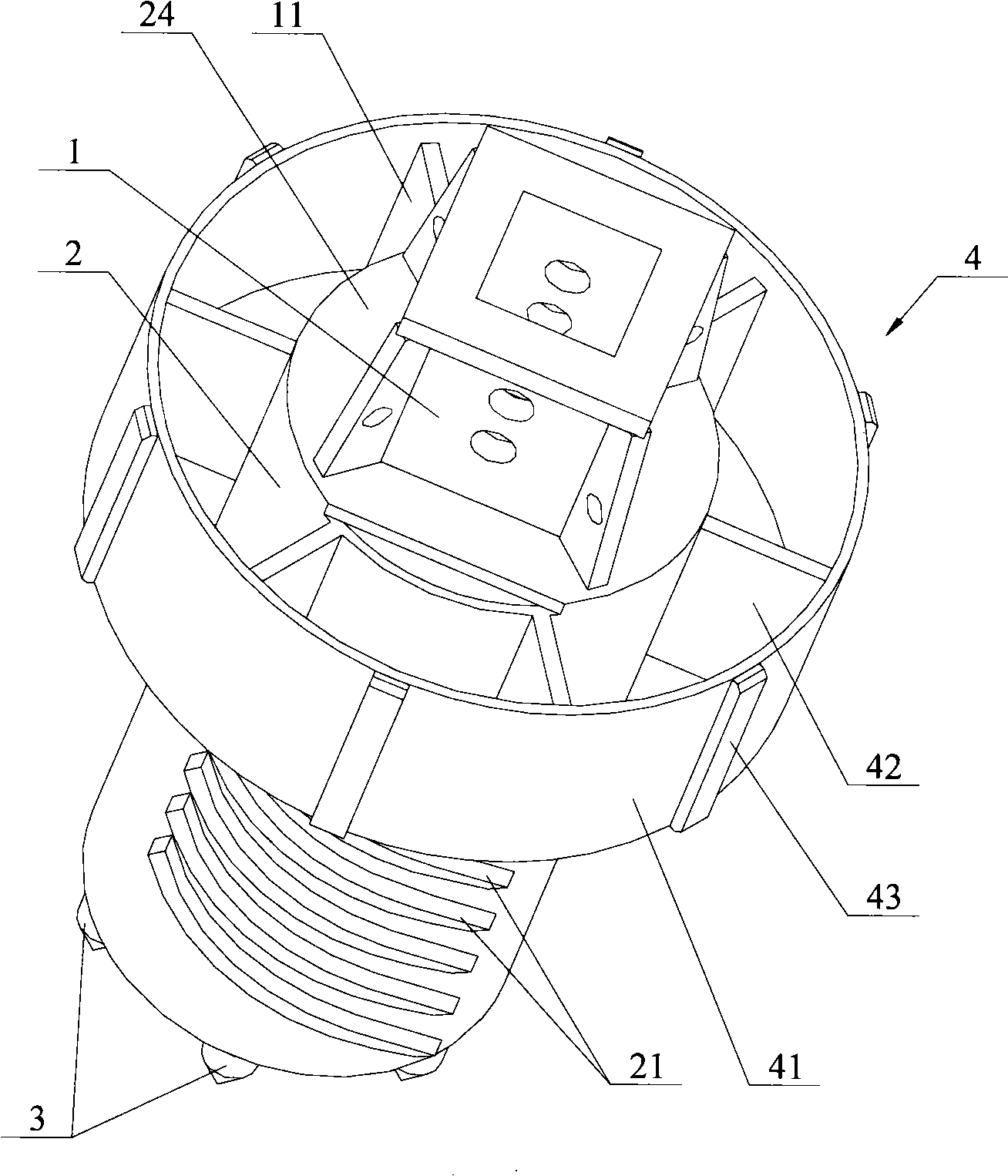

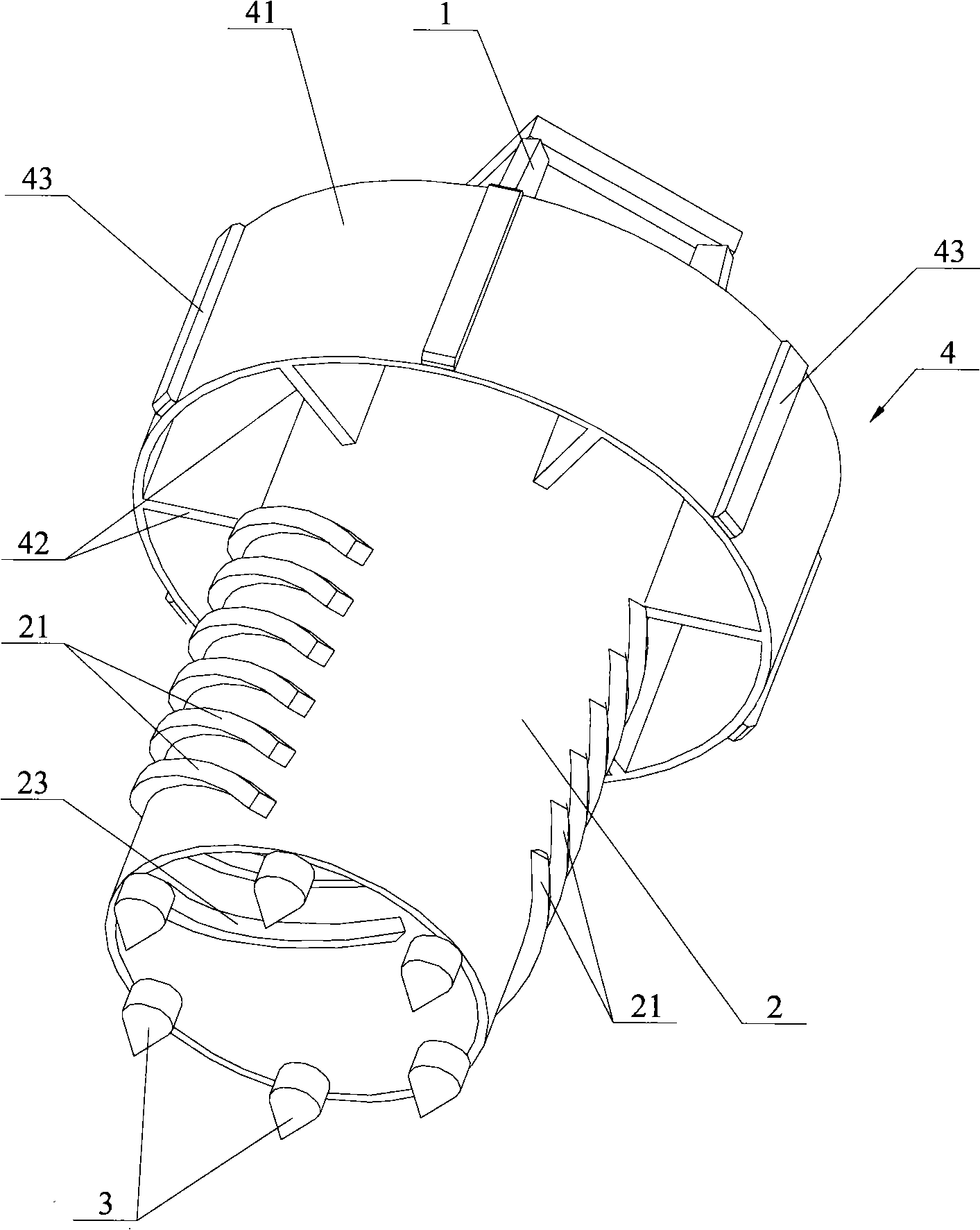

[0031] Please refer to Fig. 1, which is a perspective view of the present invention. in, Figure 1a is a stereogram based on the perspective from above, Figure 1b P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com