Dewatering industrial stove for carnaillite hydrous chloromagnesite

A technology of schlorite and industrial furnaces, applied in the direction of magnesium chloride, magnesium halide, etc., can solve problems such as unstable product quality, high energy consumption, and large safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

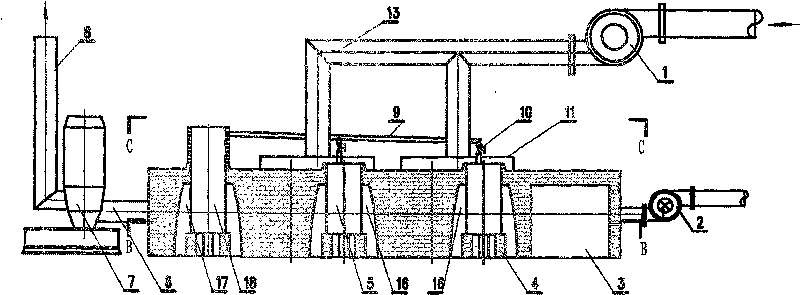

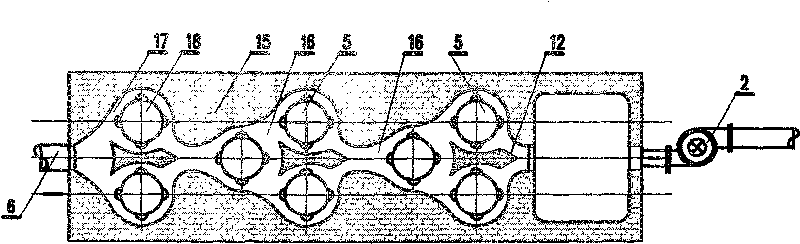

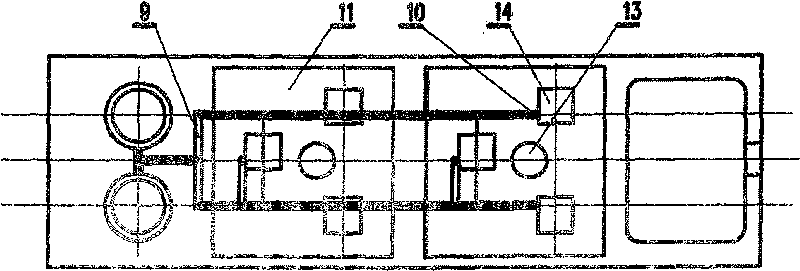

[0012] Embodiment 1 A kind of dehydration industrial furnace of carnallite adding bischofite, it is made up of coal injection machine (2), deduster (7), body of heater (15), flue gas recovery device etc., body of heater (15) There is a combustion chamber (3), two heating chambers (16), a preheating chamber (17), the coal injection machine (2) communicates with the combustion chamber (3), the combustion chamber (3) and the heating chamber ( 16) are connected, two reaction kettles (5) are arranged in the heating chamber (16), the reaction kettles (5) are supported and suspended with support (4), and the heating chamber (16) communicates with the preheating chamber (17) , two preheating kettles (18) are arranged in the preheating chamber (17), and the preheating kettle (18) is supported and suspended with the support (4), and the still mouth of the preheating kettle (18) is higher than the reaction kettle (5) The opening of the kettle, the heating chamber (16) and the preheating ...

Embodiment 2

[0013] Embodiment 2 A kind of dehydration industrial furnace of carnallite adding bischofite, it is made up of coal injection machine (2), deduster (7), body of heater (15), flue gas recovery device etc., body of heater (15) There is a combustion chamber (3), four heating chambers (16) connected in series, a preheating chamber (17), the coal injection machine (2) communicates with the combustion chamber (3), and the combustion chamber (3) communicates with the combustion chamber (3). The heating chamber (16) is connected, and four reaction kettles (5) are arranged in each heating chamber (16), and the reaction kettle (5) is supported and suspended with a support (4). (17) are connected, and two preheating kettles (18) are arranged in the preheating chamber (17), and the preheating kettles (18) are supported and suspended with support (4), and the still mouth of the preheating kettles (18) is higher than The mouth of the reactor (5), the heating chamber (16) and the preheating ...

Embodiment 3

[0014] Embodiment 3 A kind of dehydration industrial furnace of carnallite adding bischofite, it is made up of coal injection machine (2), deduster (7), body of heater (15), flue gas recovery device etc., body of heater (15) There is a combustion chamber (3), two heating chambers (16) connected in series, a preheating chamber (17), the coal injection machine (2) communicates with the combustion chamber (3), and the combustion chamber (3) communicates with the combustion chamber (3). The heating chamber (16) is connected, and three reaction kettles (5) are arranged in each heating chamber (16), and the reaction kettle (5) is supported and suspended with a support (4), and the heating chamber (16) and the preheating chamber ( 17) are connected, and two preheating stills (18) are arranged in the preheating chamber (17), and the preheating stills (18) are supported and suspended with the support (4), and the still mouth of the preheating stills (18) is higher than the reaction The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com