Conveyor with rigid carrying transmission plane and transmitting process thereof

A conveyor and rigid technology, applied in the field of conveyor and its transmission, can solve the problems of unfavorable market economic operation, large floor area, high cost, etc., achieve good use value and promotion value, low production and maintenance costs, and reduce The effect of transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

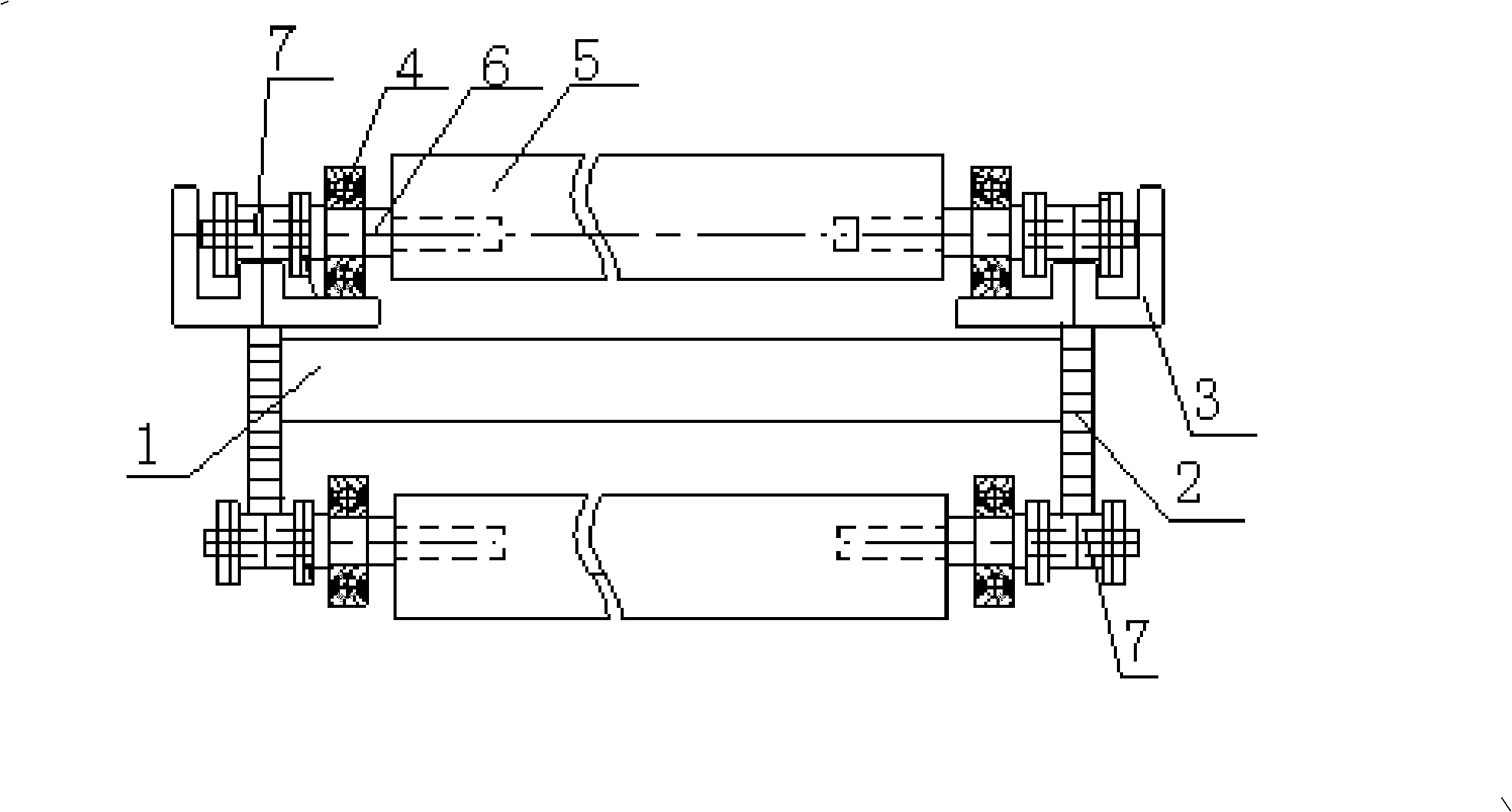

[0013] Embodiments of the present invention: When making a conveyor for conveying objects, a movable rigid carrier is used to convey objects, that is, rollers are installed on the rigid carrier as a carrier for transporting heavy objects, and multiple rigid carriers with rollers are connected by chains. Carriers are connected in series, and the rigid carriers connected in series are supported on the rigid track of the conveyor through their rollers. The chains are connected end to end, and the chains are driven by the sprockets set on the conveyor, and the chains drive the rigid carriers for circular motion. This rigid carrier conveyor is especially suitable for conveying bulky and heavy items.

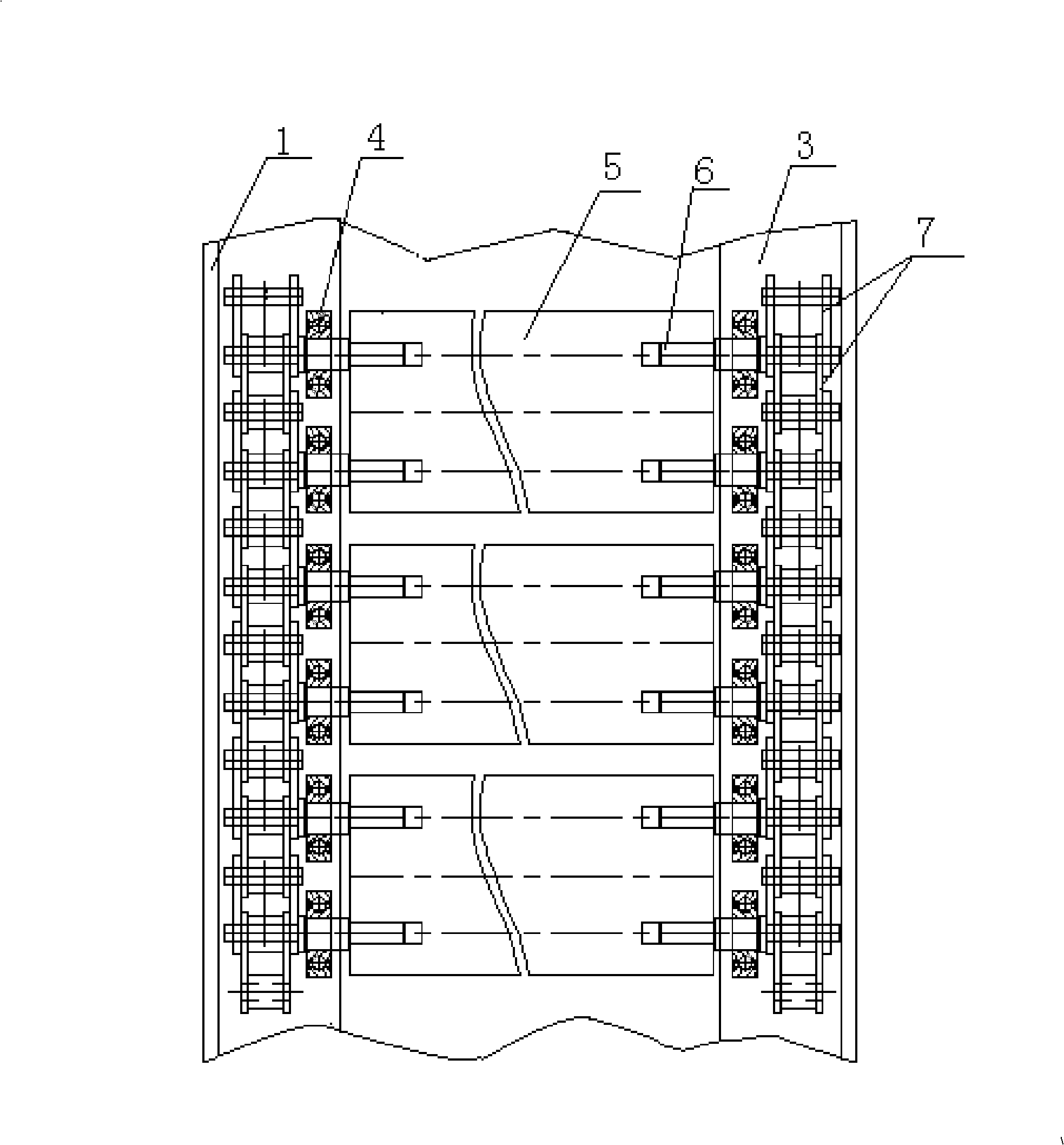

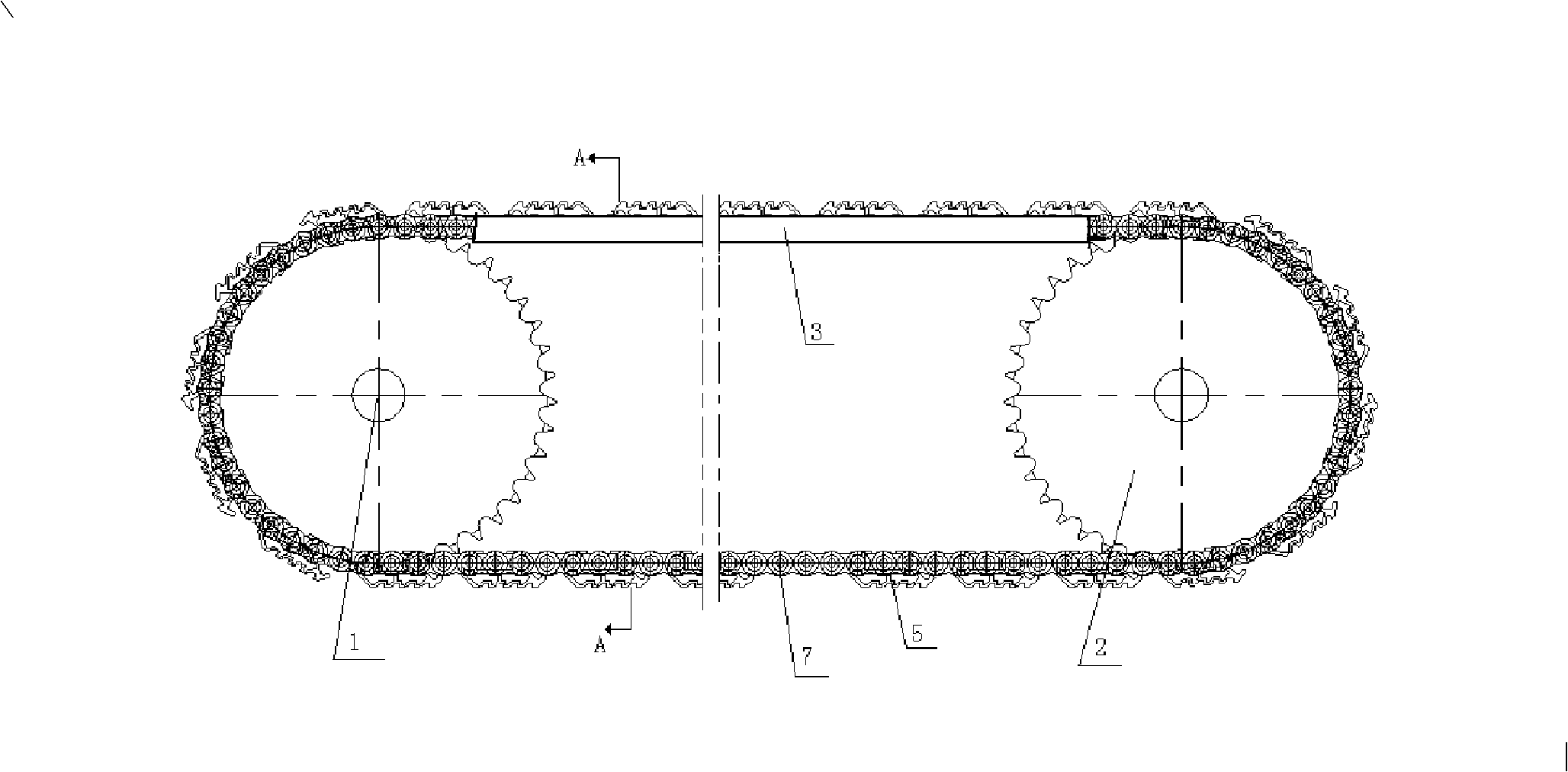

[0014] When using the above method to specifically manufacture a conveyor whose transmission surface is a rigid carrier; figure 1 , figure 2 and image 3 As shown, it includes a frame 1, a sprocket 2 driven by a motor is installed at both ends of the frame 1, a chain 7 rotating wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com