Hot melt detection integration device

A hot-melt and equipment technology, applied in the field of hot-melt detection integrated equipment, can solve the problems of reduced work efficiency, inaccurate melting and fixing of hot-melt columns, and large human factors, so as to reduce the incidence of defective products and improve The efficiency of manual work and the effect of reducing human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

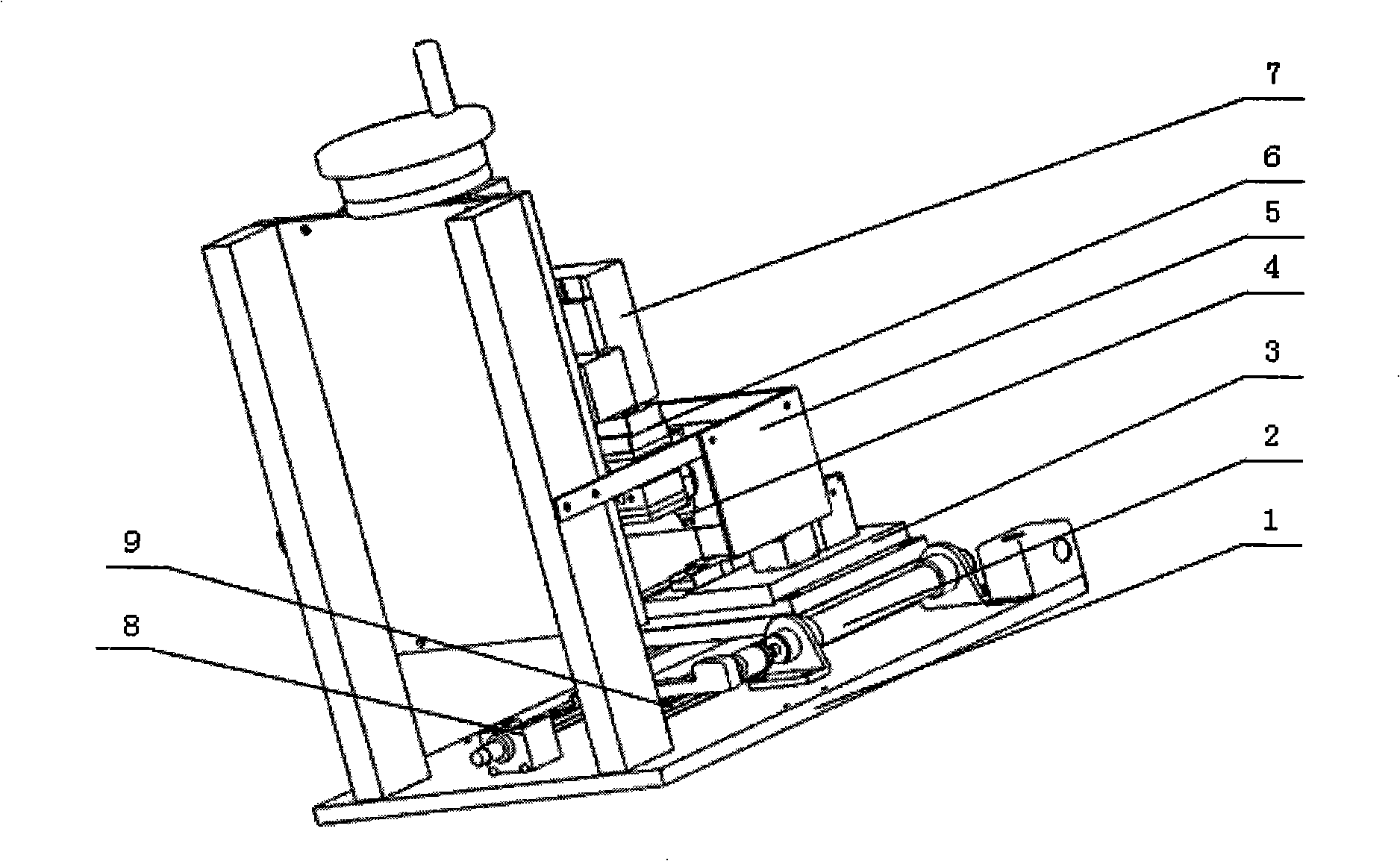

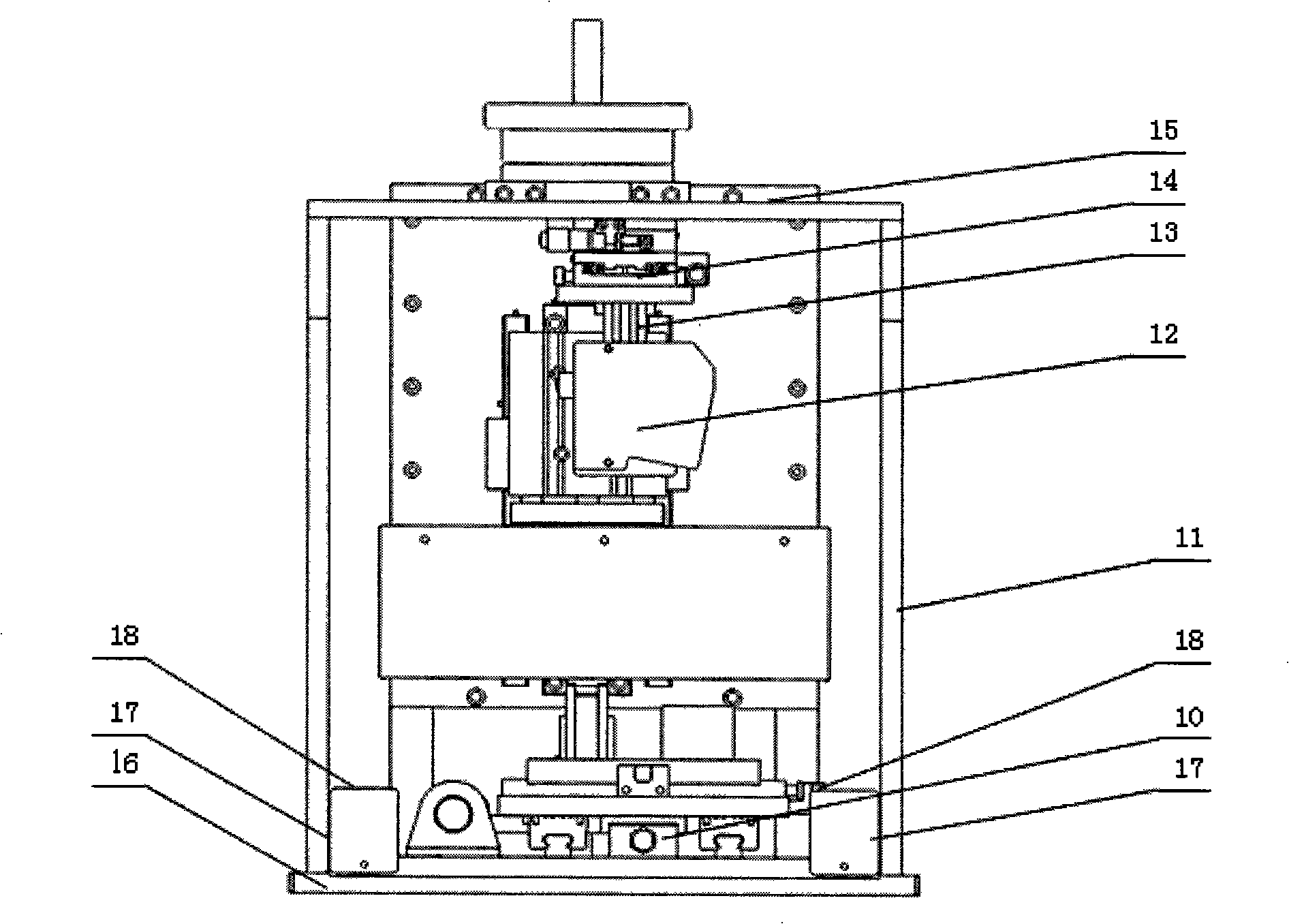

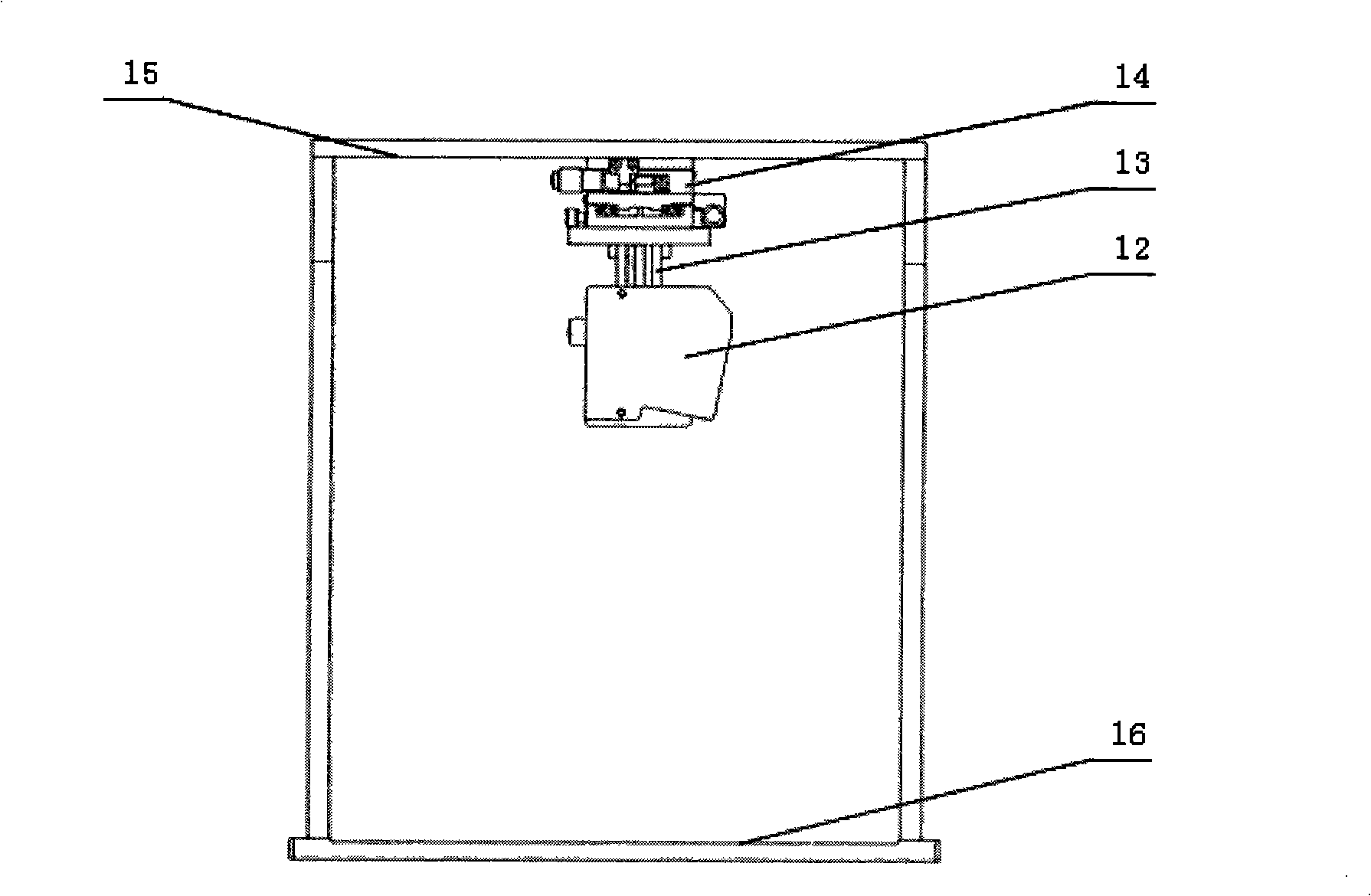

[0020] Below in conjunction with the accompanying drawings, this design is specifically introduced as follows:

[0021] figure 2 It is the front structure diagram of the hot melt detection integrated equipment of the present invention, image 3 is the front view of the supporting structure of the displacement sensor of the present invention, Figure 4 It is the left view of the supporting structure of the displacement sensor of the present invention, Figure 5 It is the operating program flow chart of the present invention.

[0022] As shown in the figure, the hot-melt detection integrated equipment of the present invention realizes the fixation of resin products and the function of checking the work of employees, ensures the accuracy of the position of hot-melt parts, that is, prevents the occurrence of defective products.

[0023] Including hot melt machine and automatic detection device. It is characterized in that one or more parts placed on the workbench are heated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com