Method for eliminating three-ring speed reducer gear engagement impact

A reducer and meshing technology, applied in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of environmental pollution, increase noise, affect the service life of bearings, etc. The effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

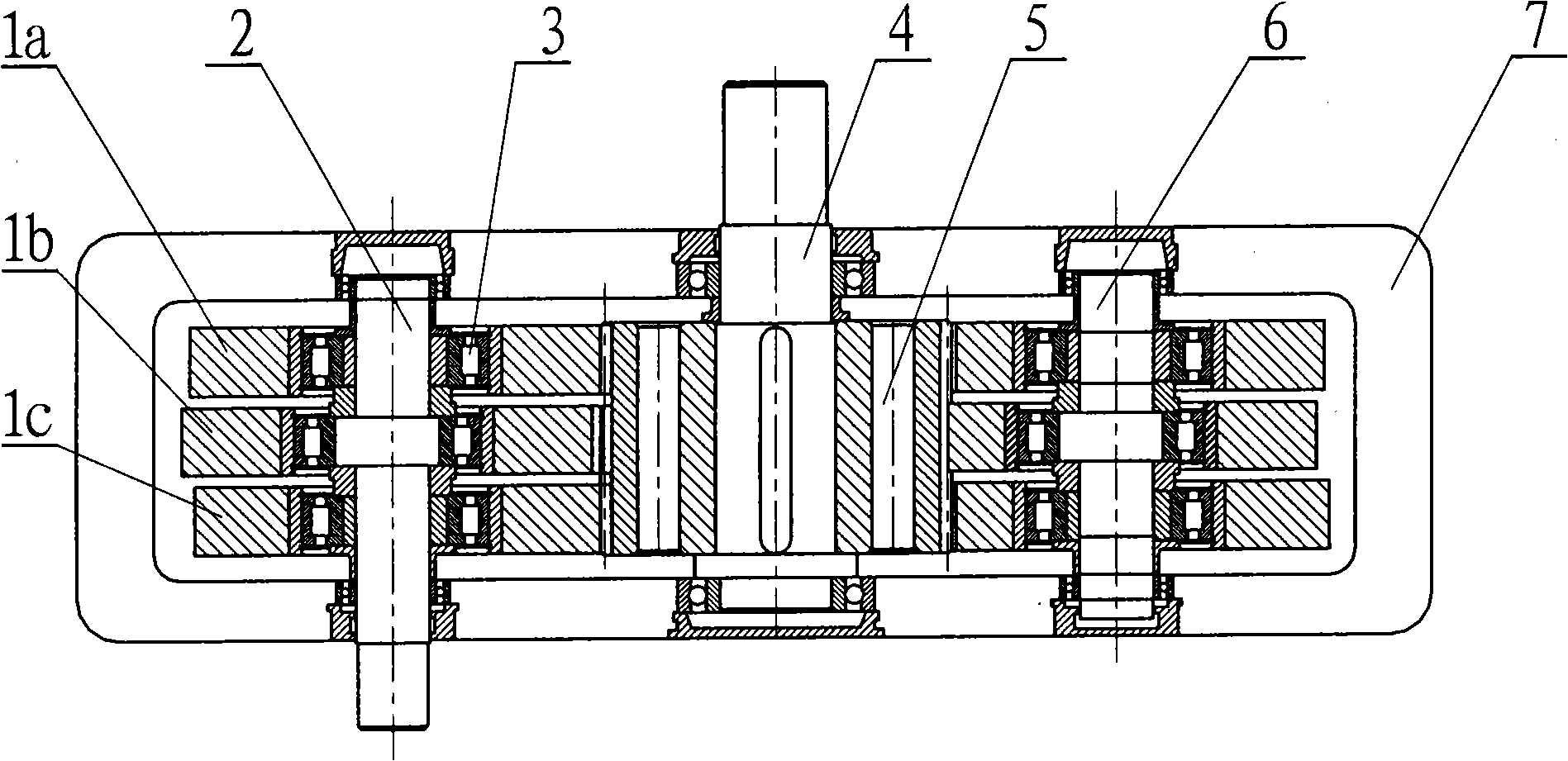

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] The invention provides a method for eliminating the gear meshing impact of a three-ring reducer. The method is carried out as follows:

[0035] (1). According to the size and positional relationship of the three-ring reducer, draw the mechanism diagram of the meshing process between the inner gear ring plate and the outer gear;

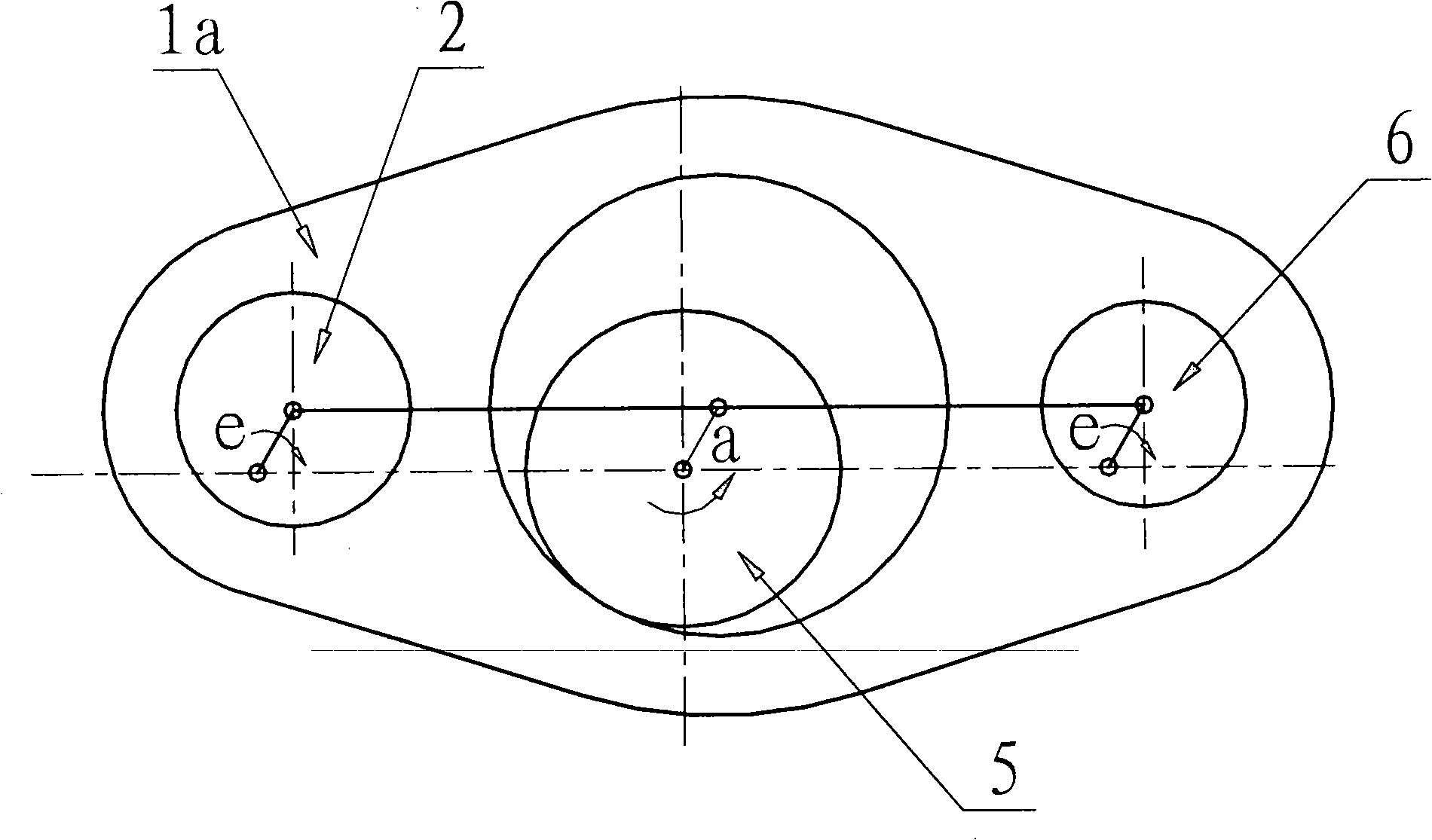

[0036] Such as figure 2 As shown, it can be seen from the kinematic characteristics of the planar four-bar mechanism that the inner gear ring plate 1a and the outer gear 5 form an inner meshing gear pair, and the center distance a of the gear pair is equal to the eccentric distance e of the first high-speed shaft 2 and the second high-speed shaft 6 .

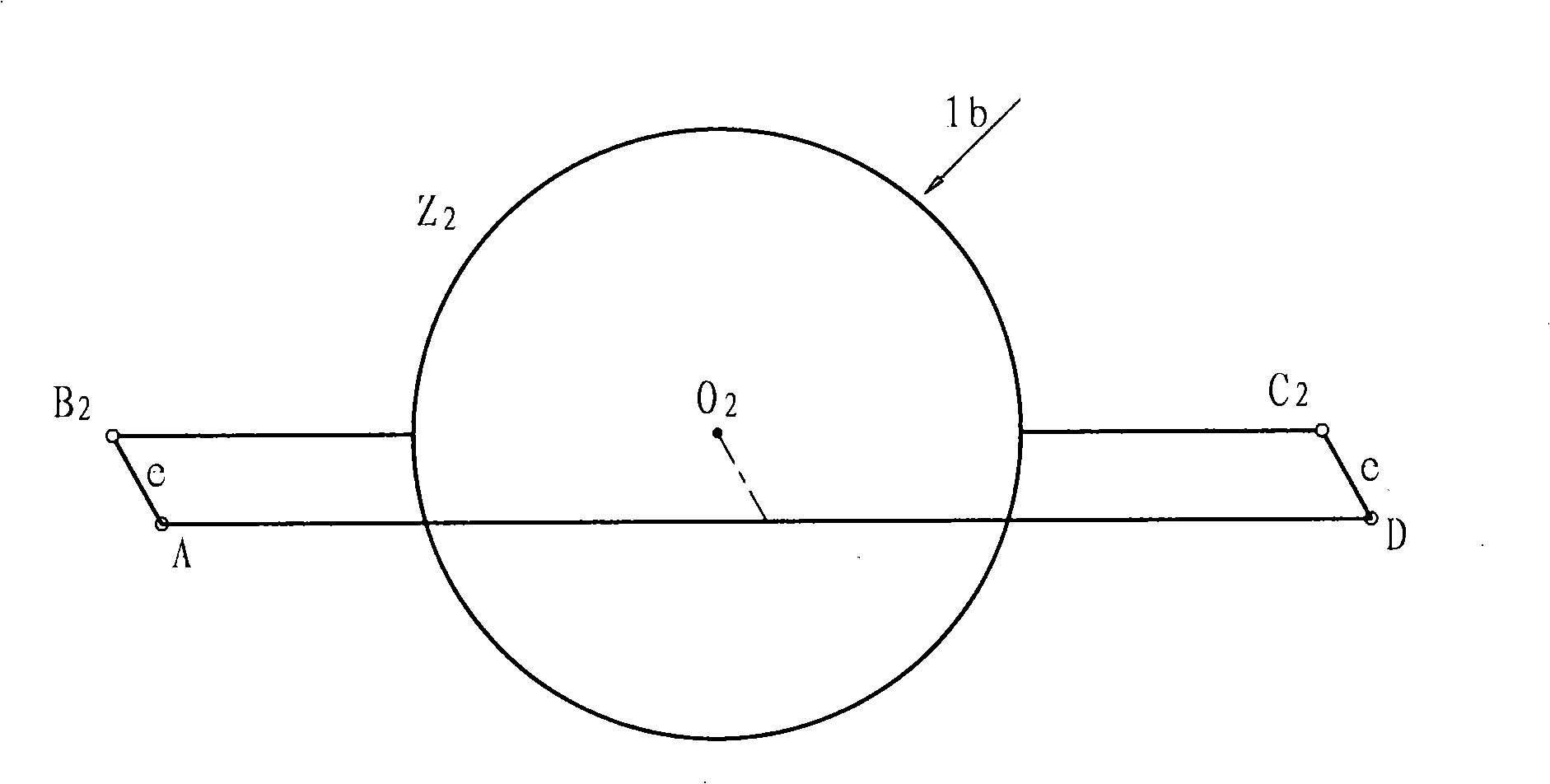

[0037] Figure 5 It is a schematic diagram of the superposition motion of the three-phase parallel planar four-bar mechanism in the three-ring reducer, AB in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com