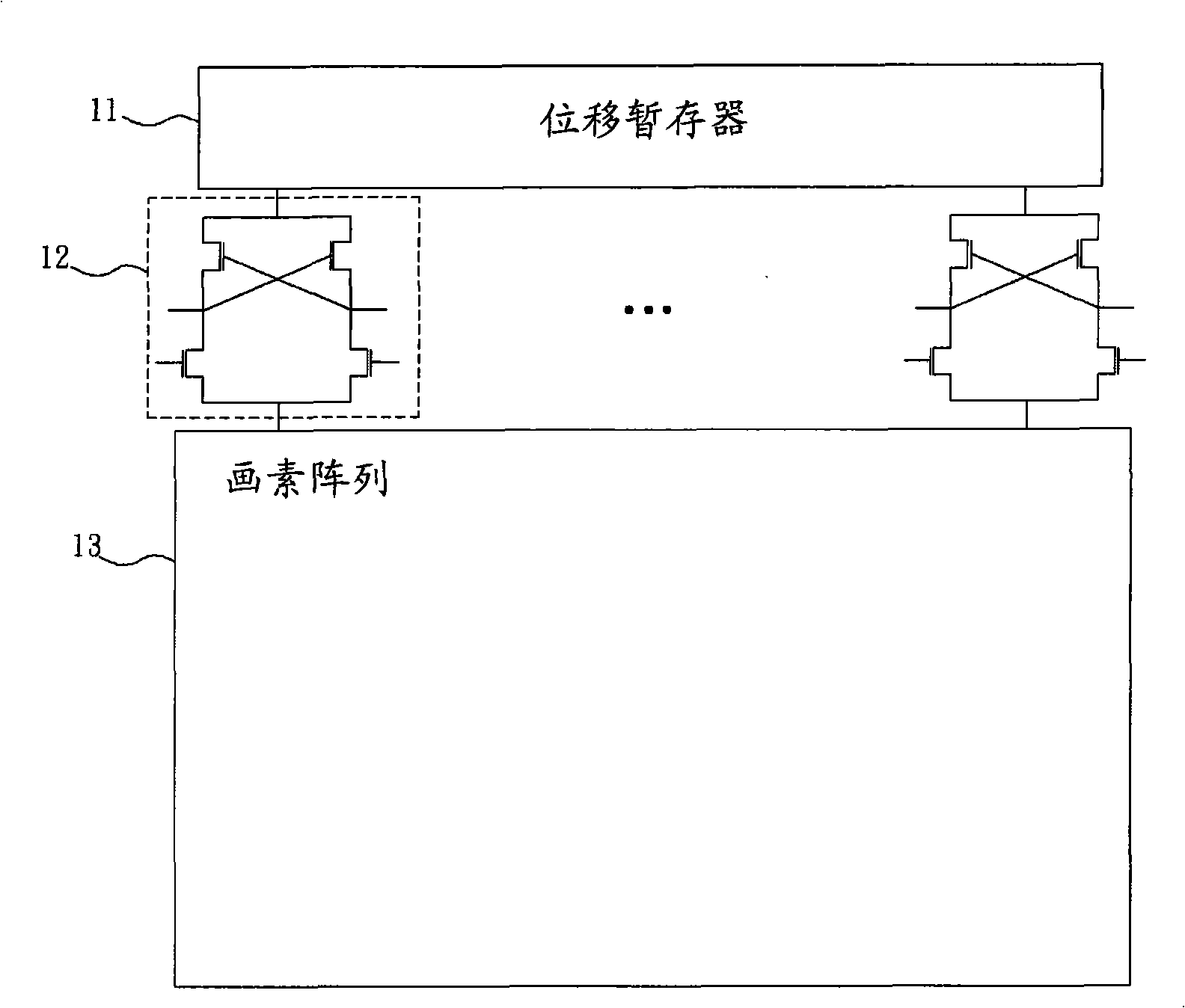

Electronic paper device, and its driving circuit and production method

A technology of driving circuit and manufacturing method, applied in the direction of cathode ray tube indicator, instrument, static indicator, etc., can solve the problems of huge cost and uneconomical efficiency, and achieve the effect of reducing cost and simple driving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

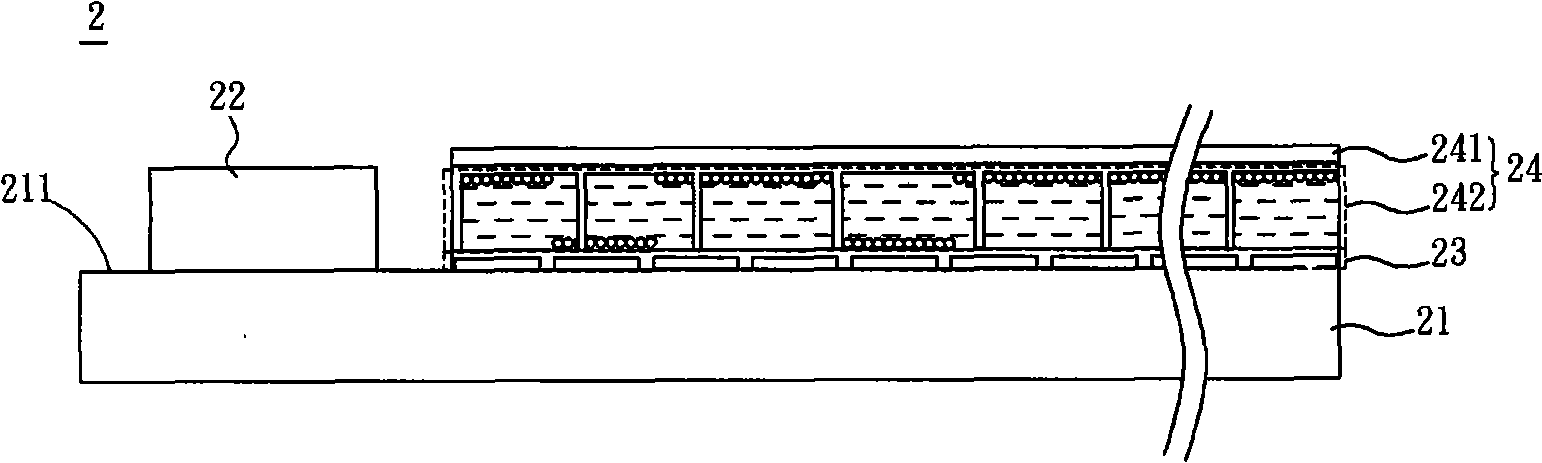

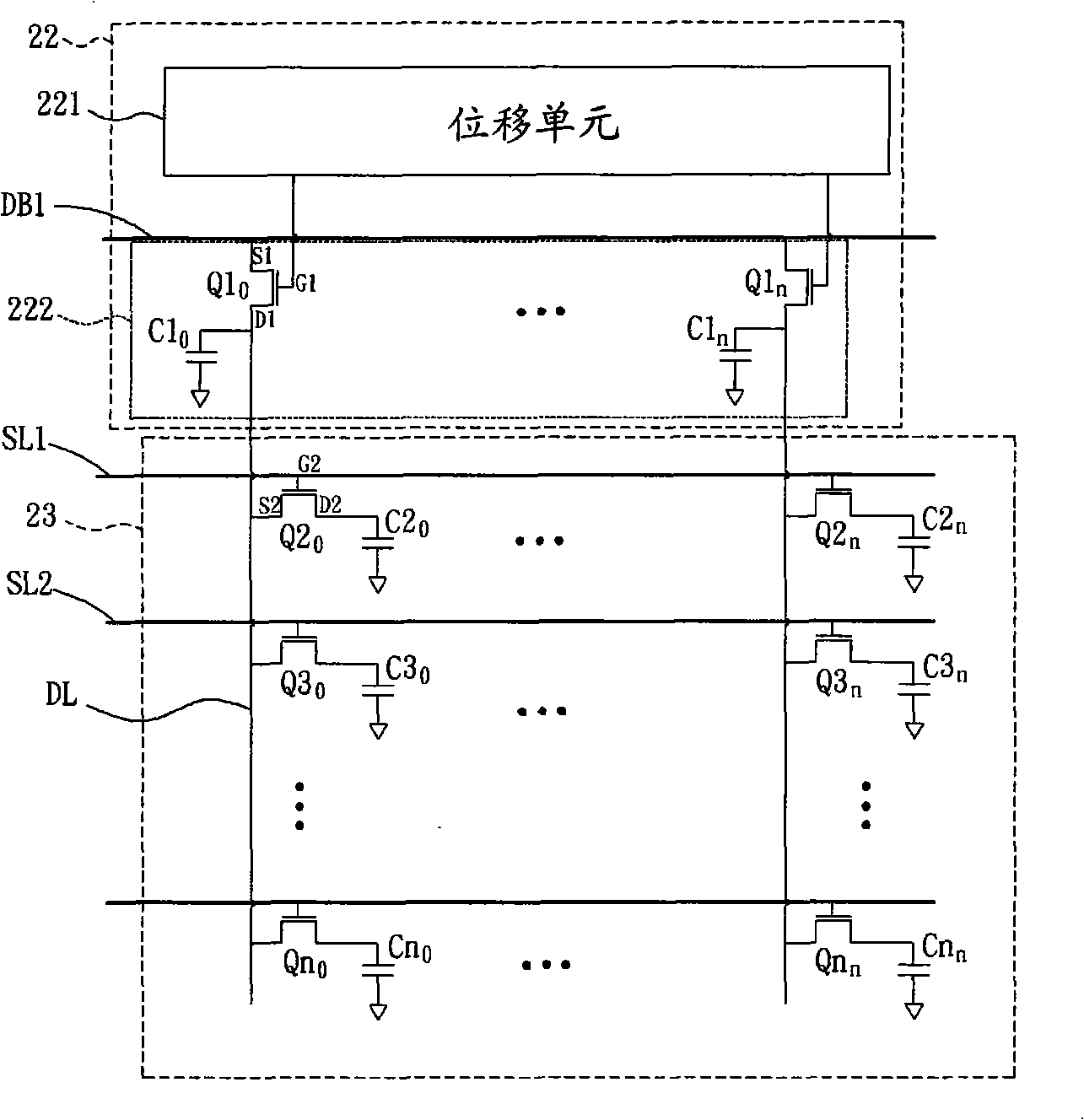

[0066] Please refer to figure 2 As shown, the electronic paper device 2 of the preferred embodiment of the present invention includes a substrate 21 , a driving circuit 22 , a pixel array 23 and an electronic paper 24 . Wherein, the driving circuit 22 and the pixel array 23 are arranged on a surface 211 of the substrate 21 , and the driving circuit 22 and the pixel array 23 are arranged adjacent to each other; the electronic paper 24 is arranged opposite to the pixel array 23 . The electronic paper 24 includes a pair of electrode units 241 and an electrophoretic substance unit 242 . The opposite electrode unit 241 is disposed opposite to the pixel array 23 , and the electrophoretic substance unit 242 is disposed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com