Rail-changing traction system

A traction system and track-changing technology, applied in the field of traction systems, can solve the problems of occupying land, occupying rails, and failing to meet actual needs, and achieve the effects of convenient assembly, not easy to derail, and easy to automate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

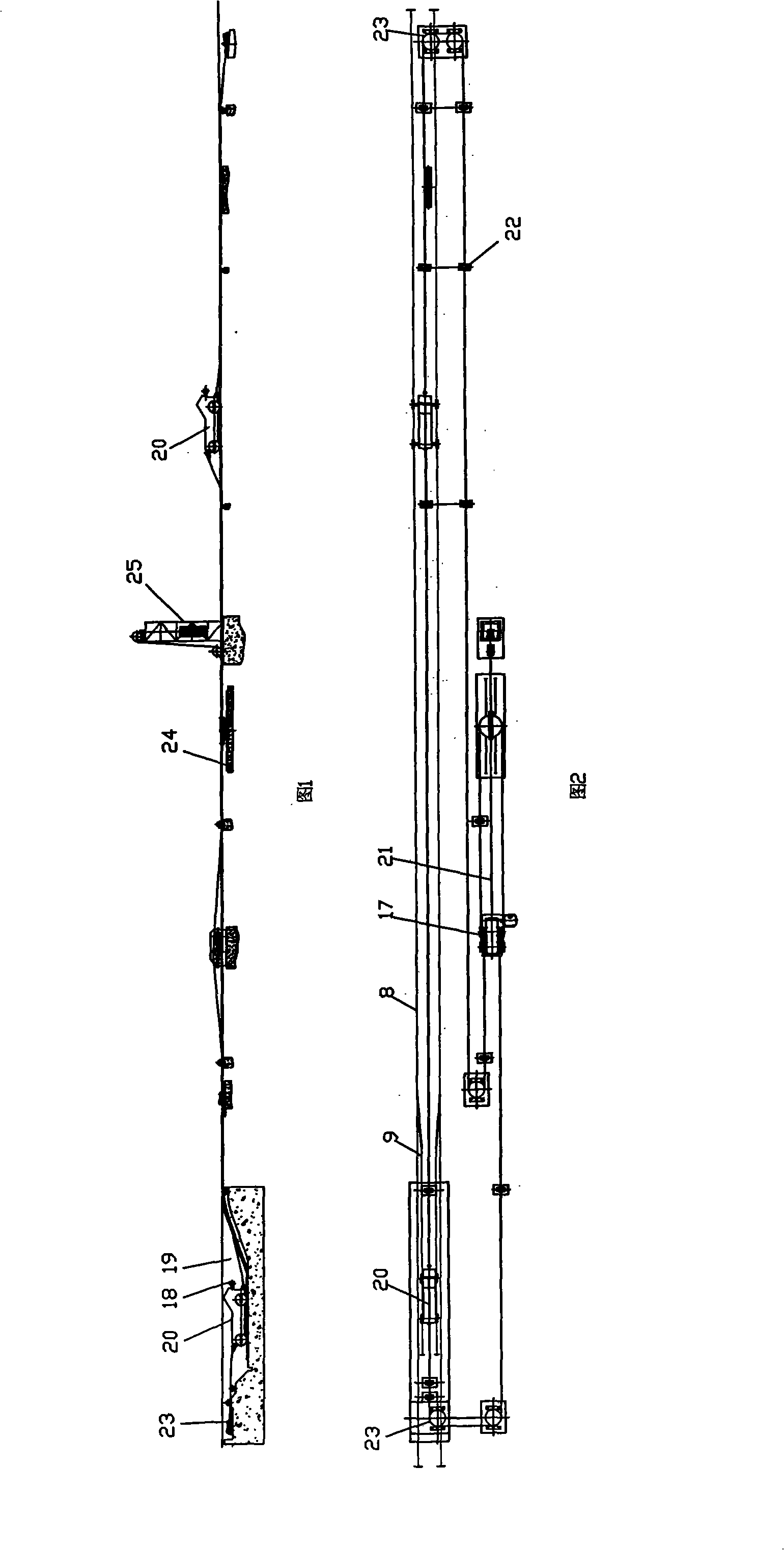

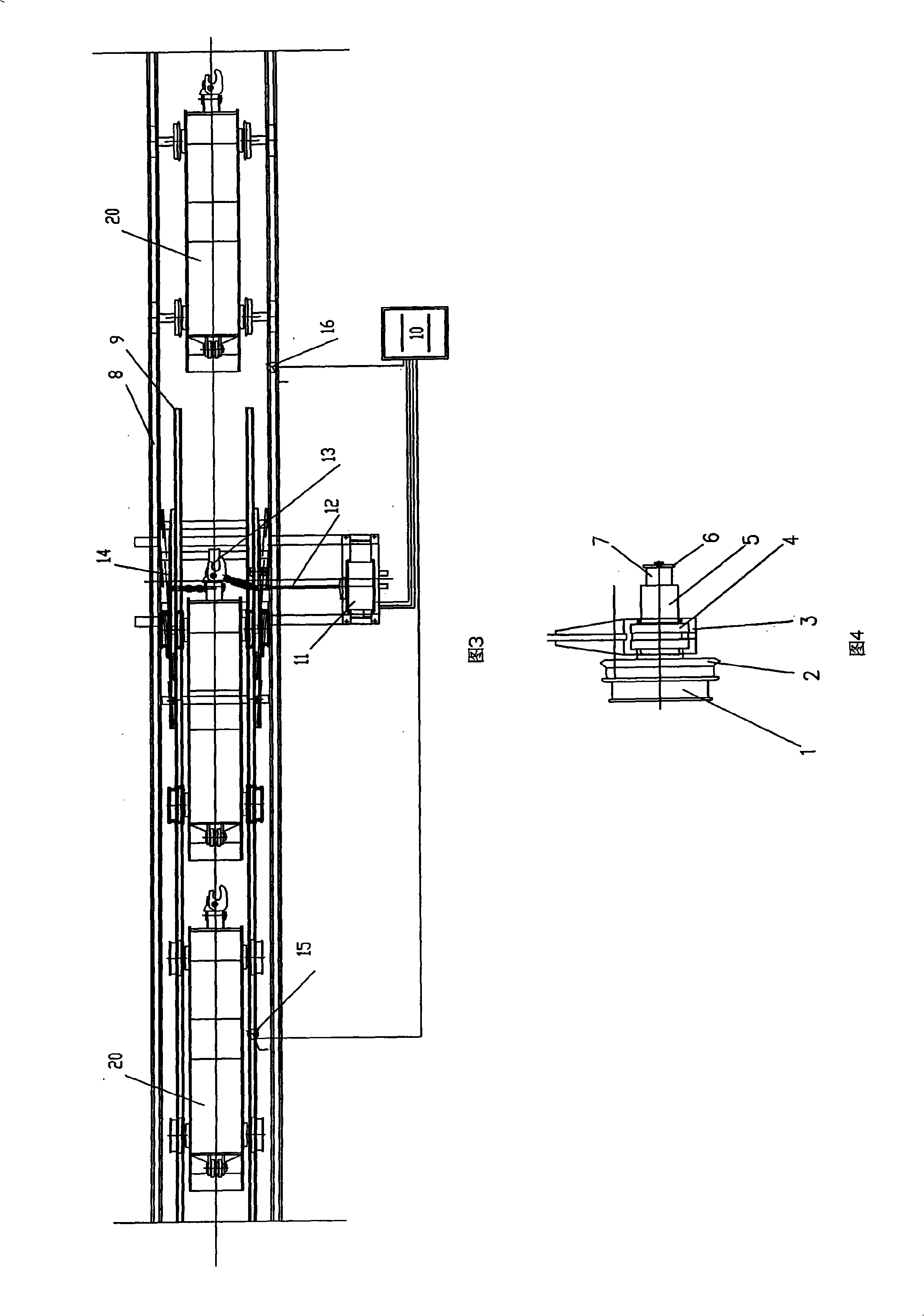

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Among Fig. 1, Fig. 2, it comprises track-changing type traction device 20, and it is a trolley, and its bottom installation is made of four sets of track-changing wheel trains. The track-changing traction device 20 is installed on the standard rail 8 and the auxiliary track 9 within the standard rail 8 with a spacing smaller than the standard rail 8 by the track-changing traveling wheel train. A track changing device is installed between the auxiliary track 9 and the standard track 8, and a pit 19 is provided on the railway subgrade at the end of the auxiliary track 9. The depth of the pit 19 should ensure that when the track changing traction device 20 is located inside, the track changing type The top of the traction device 20 is below the standard rail 8 .

[0029] The track-changing traction device 20 also includes a motor, a base, a shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com