Statistical signatures used with multivariate statistical analysis for fault detection and isolation and abnormal condition prevention in a process

一种多元统计分析、多元统计的技术,应用在预测诊断能力领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

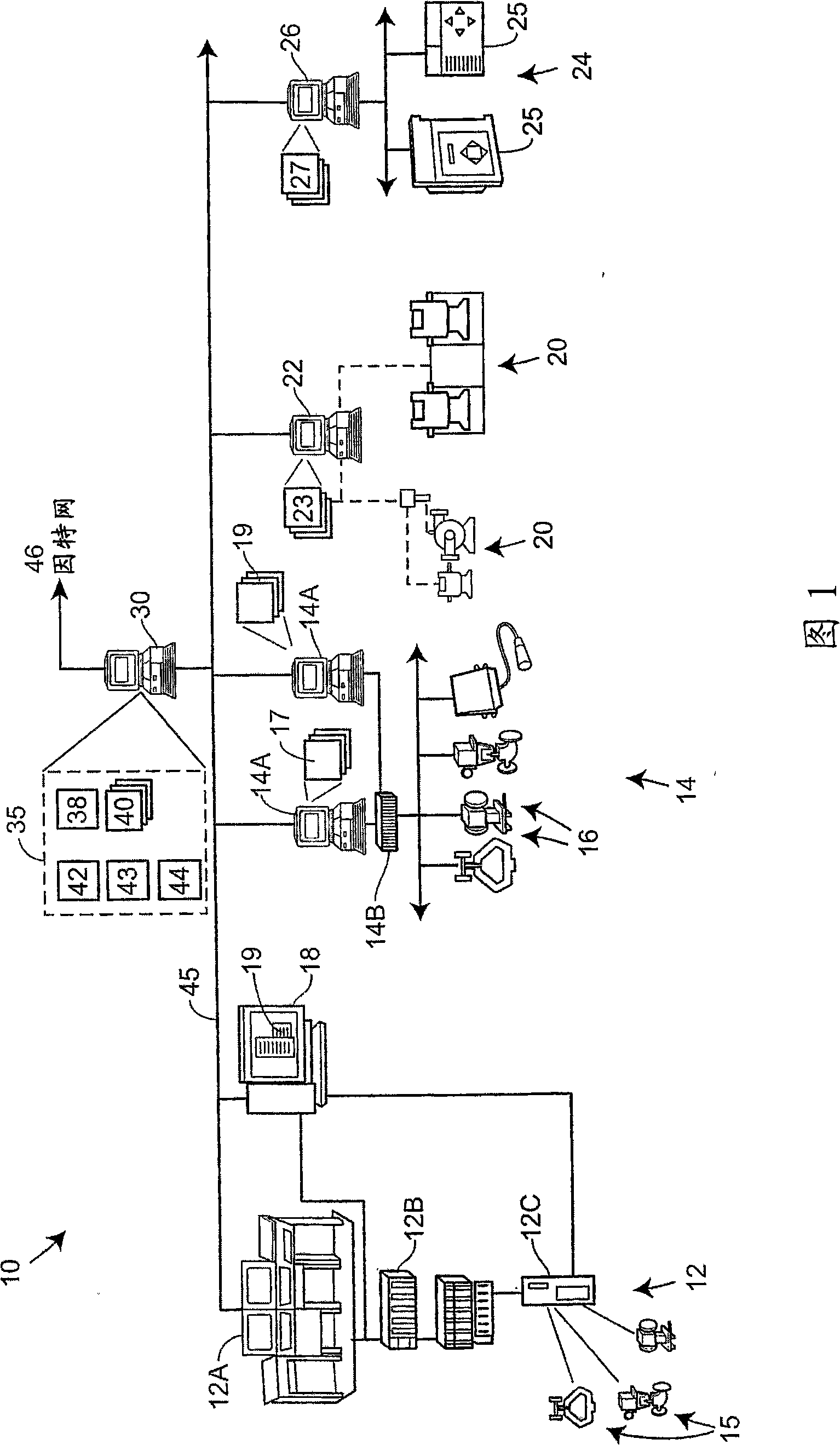

[0037] Referring to FIG. 1 , an example process plant 10 in which a fault detection and isolation system may be implemented includes a plurality of control and maintenance systems interconnected with auxiliary equipment by one or more communication networks. In particular, process plant 10 of FIG. 1 includes one or more process control systems 12 and 14 . Process control system 12 may be a conventional process control system, such as a PRO VOX or RS3 system, or any other control system that includes an operator interface 12A connected to a controller 12B and an input / output (I / O) card 12C, the operator Interface 12A, controller 12B, and input / output (I / O) card 12C are in turn connected to, for example, analog and high-speed addressable remote transducers (HART ) on various field devices of the field device 15. Process control system 14 may be a distributed process control system including one or more operator interfaces 14A connected to one or more controllers 14B via a bus,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com