Glass kiln natural gas oxygen-enriched combustor

A technology of oxygen-enriched combustion and glass kiln, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of reducing air excess coefficient, increasing heat utilization rate, and large heat loss, so as to reduce air excess coefficient , increase the heat utilization rate, and promote the effect of complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

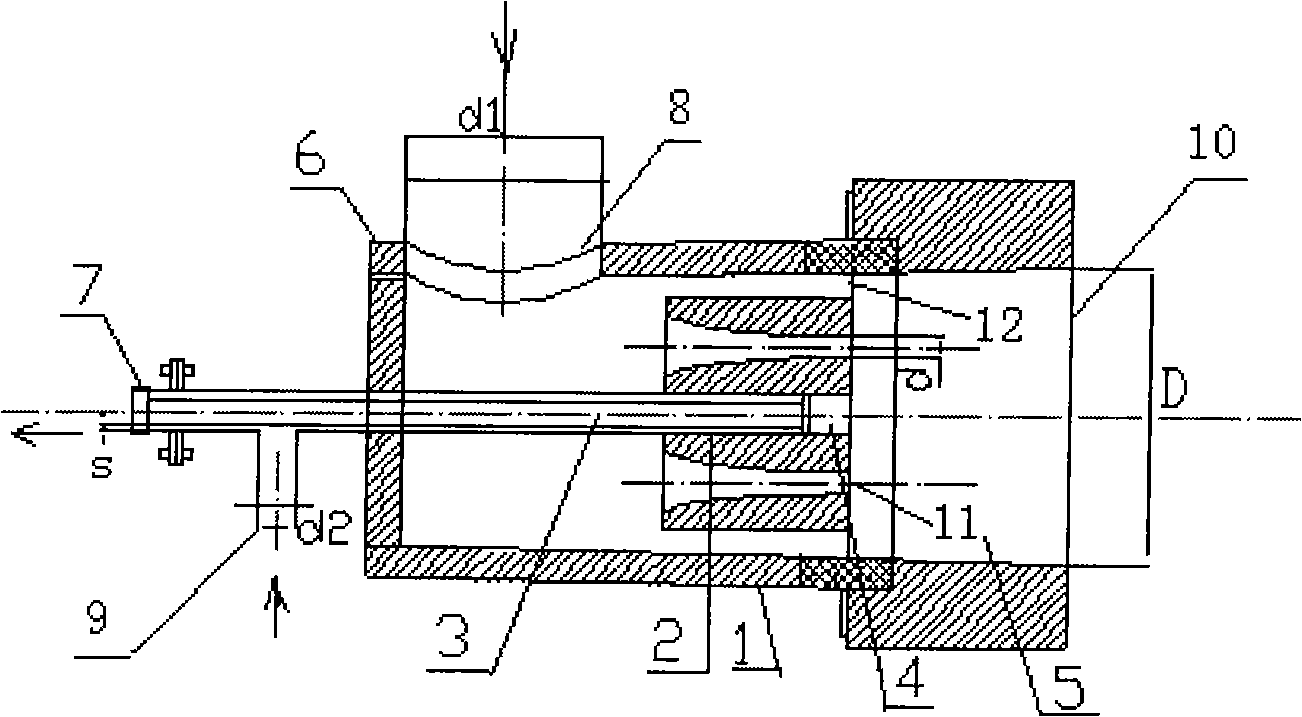

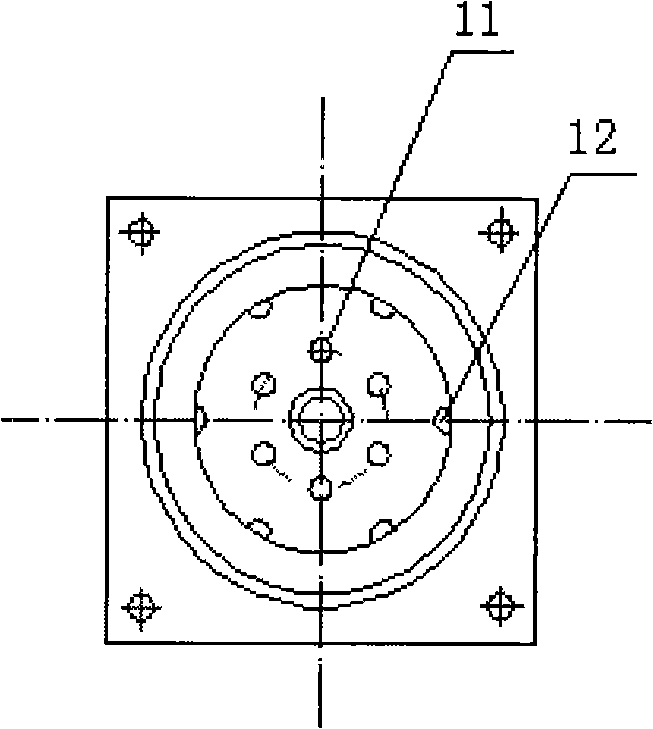

[0009] Such as figure 1 The cross-sectional structural schematic diagram of the natural gas oxygen-enriched burner of the glass kiln is shown. The burner includes a shell 1, a natural gas conduit 2, a liner 3, an oxygen-enriched air diversion guide brick 4, a mixing chamber 5, a baffle plate 6, a plug 7, and a shell 1. The inner cavity is a cylinder, which is divided into front and rear parts. There is a diameter d on the front part of the shell 1. 1 The oxygen-enriched air injection inlet 8, the rear part is the mixing chamber 5, and the middle is as figure 2 The schematic cross-sectional view of the burner has six circular holes 11 and six approximately semicircular holes 12 on the periphery. Oxygen-enriched air flows out through the six circular holes in the middle of the burner and six approximately semicircular holes on the periphery. The mixing chamber 5 has a diameter of D The oxygen-enriched air injection port 10, part of the natural gas conduit 2 is located in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com