Regularly arranged front shock-absorbing assembled device

A combined device, front shock absorption technology, applied in axle suspension, transportation and packaging, bicycle accessories, etc., can solve the problems affecting the riding comfort of motorcycles, the length of the shock absorber spring, and the increase in the weight of the shock absorber, etc. Achieve the effect of improving smoothness, reducing the requirements for parts processing and saving weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

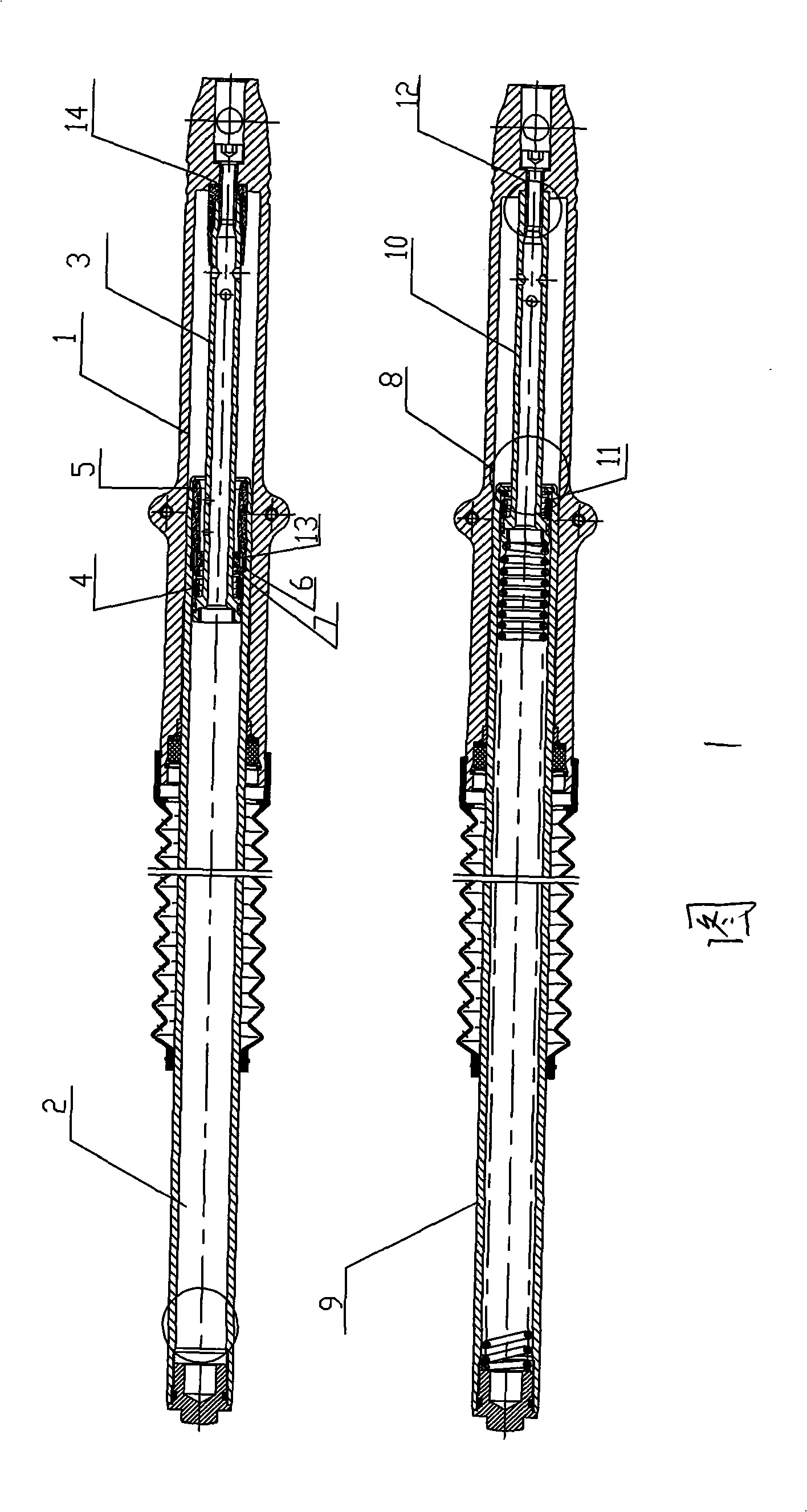

[0010] In Fig. 1, the present invention provides a kind of upright type front damping combination device, it comprises compression shock absorber and restoration shock absorber, and compression shock absorber and restoration shock absorber are asymmetric structures, and restoration shock absorber The upper part is the front fork tube I 1, the lower part is the base tube I 2, the base tube I 2 is inserted into the front fork tube I 1, and the piston rod I 3 is arranged in the front fork tube I 1, and the piston rod I 3 extends into the base tube One end of I 2 is covered with a damping spring I 4 and a damping sleeve 5, the other end of the piston rod I 3 is set in the rod seat I 14 of the front fork tube I 1, and the damping spring I 4 and the damping sleeve 5 are located in the base cylinder I 2 Inside, a fixed seat 6 is provided between the damping spring I4 and the damping sleeve 5, a damping orifice 7 is provided between the fixed seat 6 and the piston rod I3, and an elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com