Electromagnetic induction heating type electric hair drier

An electromagnetic induction heating and hair dryer technology, applied in induction heating, induction heating devices, applications, etc., can solve problems such as use environment, energy saving, safety noise, etc., achieve uniform flow rate and temperature distribution, strong safety performance, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

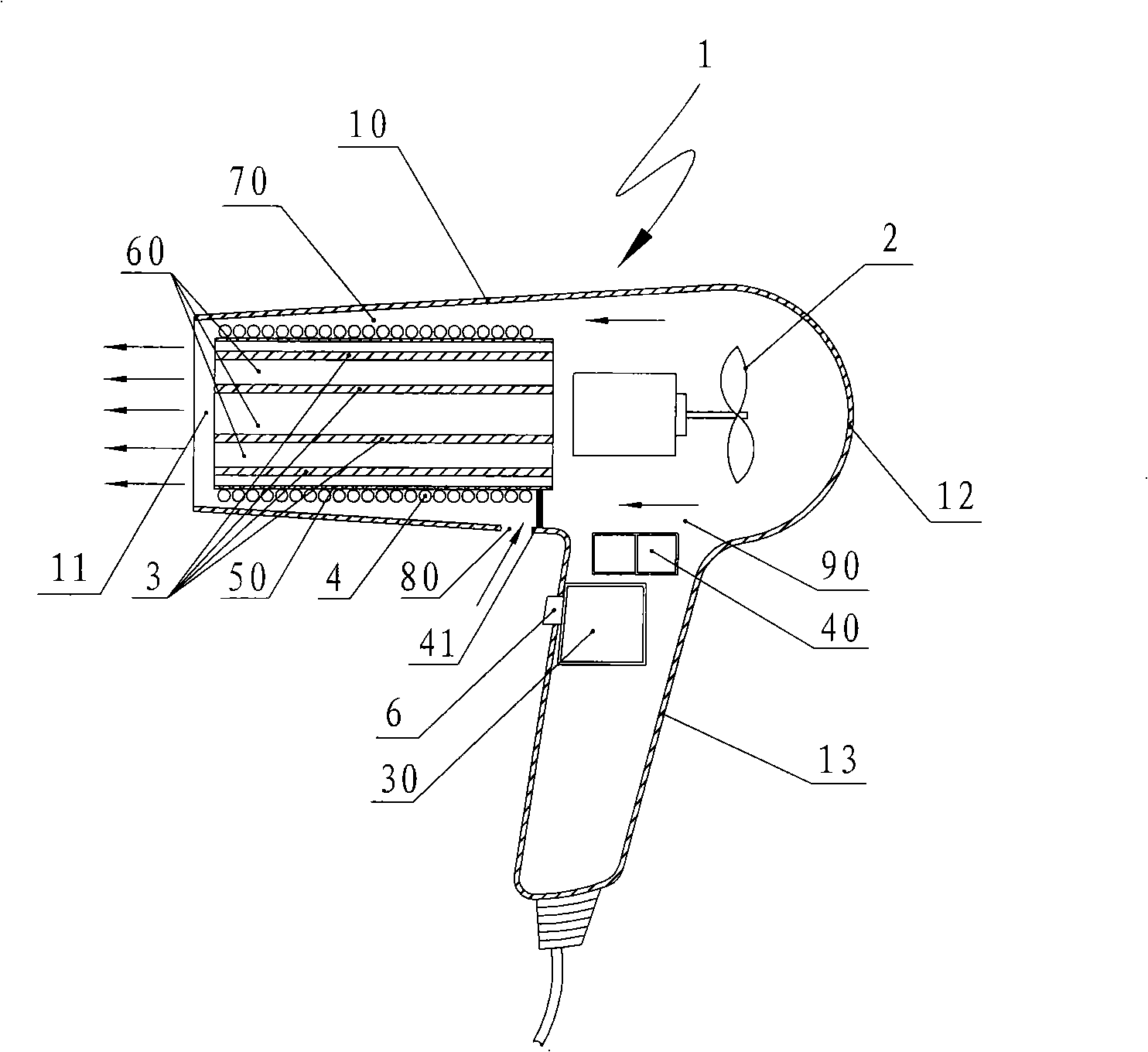

[0041] Such as Figure 1A with Figure 1B As shown, the hair dryer 1 of the present embodiment mainly includes a tubular hollow main casing 10, one end of which has an airflow inlet 12, and the opposite end has an airflow outlet 11, and a handle casing 13 with a switch 6 is formed from the hollow main casing 10. It extends downward and is integrated with the hollow main casing 10 , and the upper end 90 of the handle casing 13 is an open surface.

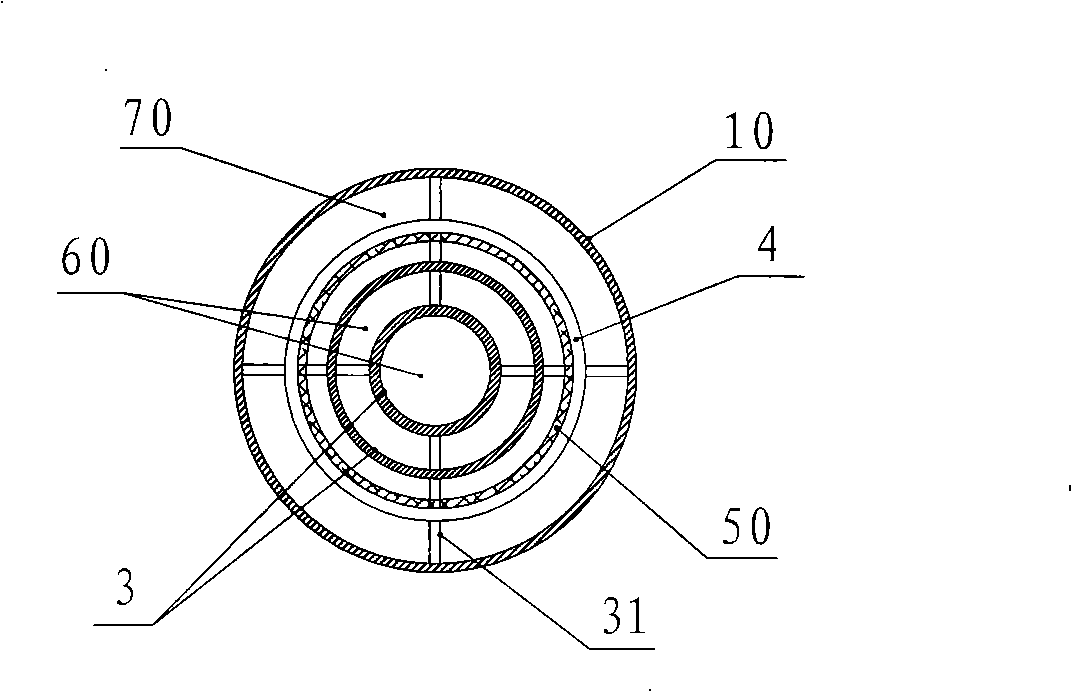

[0042] In the main housing 10, the fan 2 is disposed between the air inlet 12 and the air outlet 11, and defines a pair of first air flow passage 60 and second air flow passage 70, the first air flow passage 60 and the second air flow passage 70 Extending toward the air outlet 11 , the first air flow channel 60 and the second air flow channel 70 are separated from each other by a tubular partition wall 50 . In the present embodiment, the tubular partition wall 50 is formed by a cylindrical tube made of mica sheet, which is arranged...

Embodiment 2

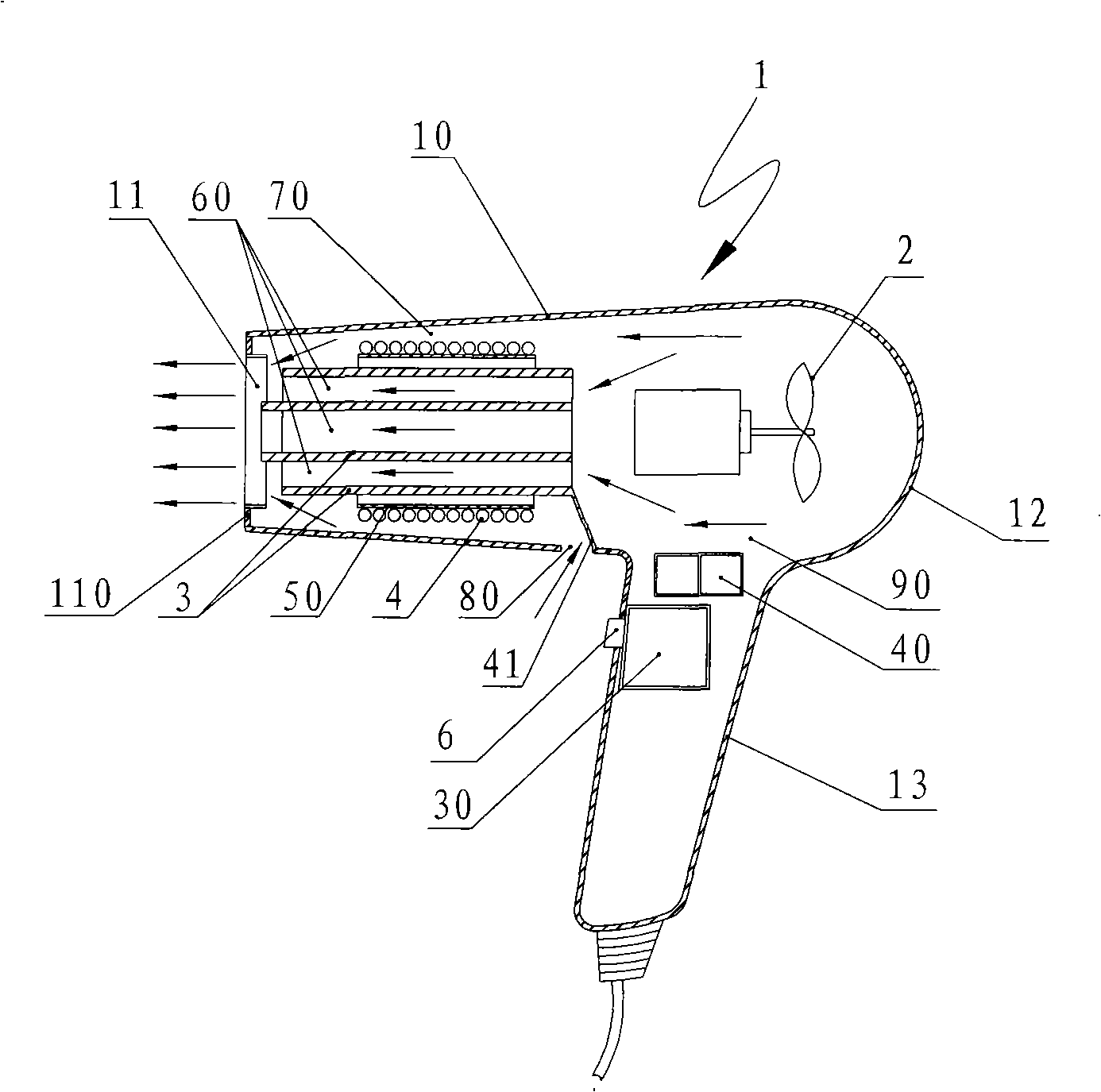

[0048] Except for the following features, the hair dryer of this embodiment is basically the same as the hair dryer of Embodiment 1. Therefore, repeated explanations are omitted.

[0049] In this example, if figure 2 As shown, the cylindrical thin-walled tube as the heat generating part 3 in the first airflow passage 60 extends further to the airflow outlet of the hair dryer 1 than the tubular partition wall 50 as the partition wall between the first airflow passage 60 and the second airflow passage 70 11, and an annular retaining ring 110 is added on the airflow outlet 11 section to prevent the airflow from the second airflow passage 70 from directly jetting out of the airflow outlet 11, so that the electromagnetic coil 4 is carried out through the second airflow passage 70 After the cooled air flow comes out from the second air flow channel 70 , it first merges into the first air flow channel 60 , and then sprays out from the air flow outlet 11 of the hair dryer 1 . There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com