Crimping die for shell crimping

A technology of tight mouth and shells, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of high energy loss, low mechanical efficiency, and large force on the mechanism, so as to avoid huge friction, prolong the life of the equipment, and improve the mechanical efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

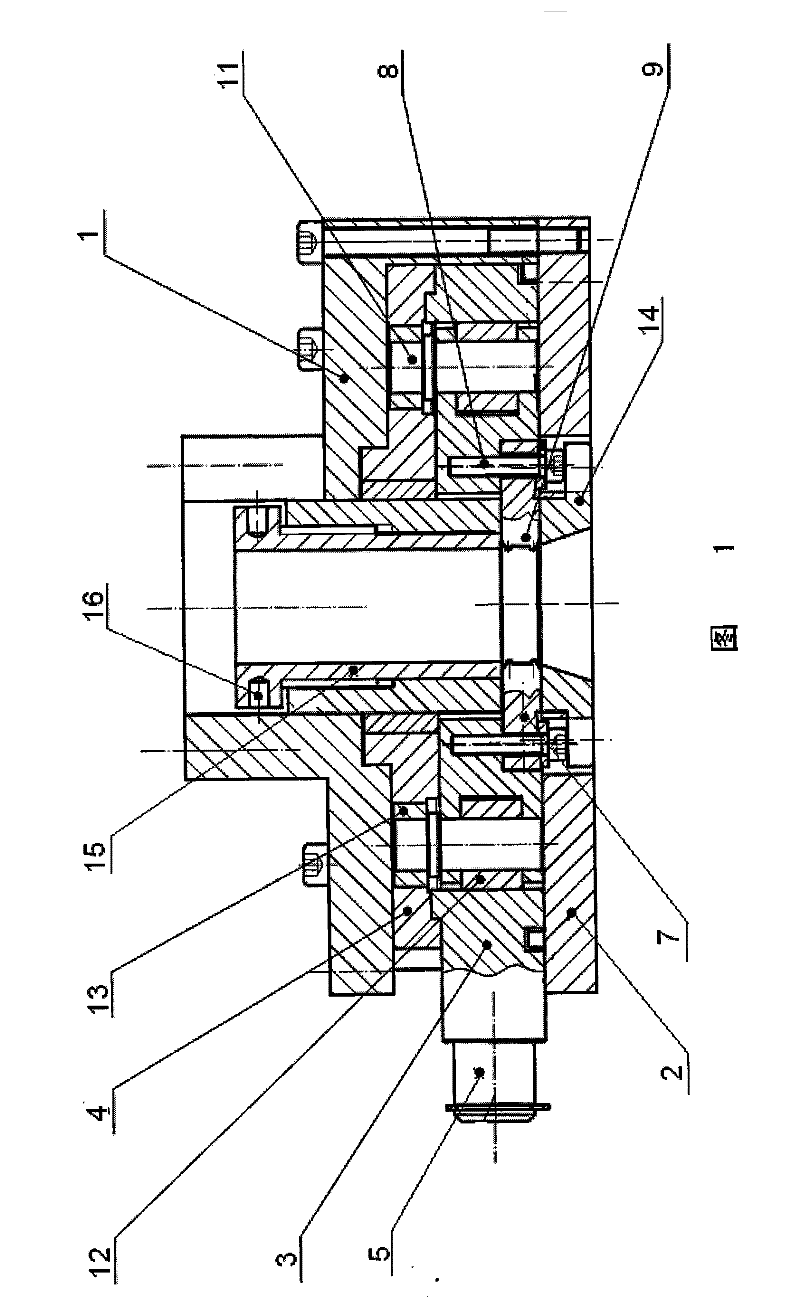

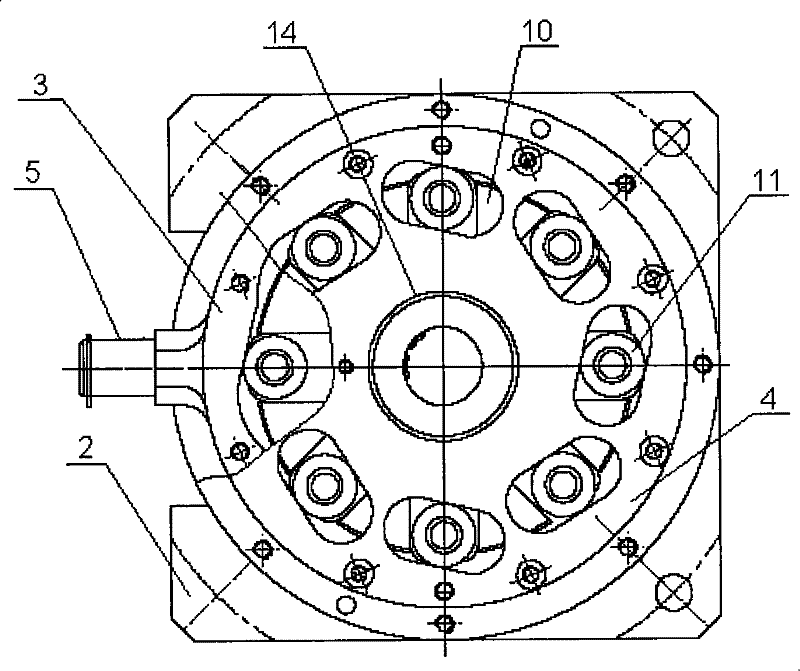

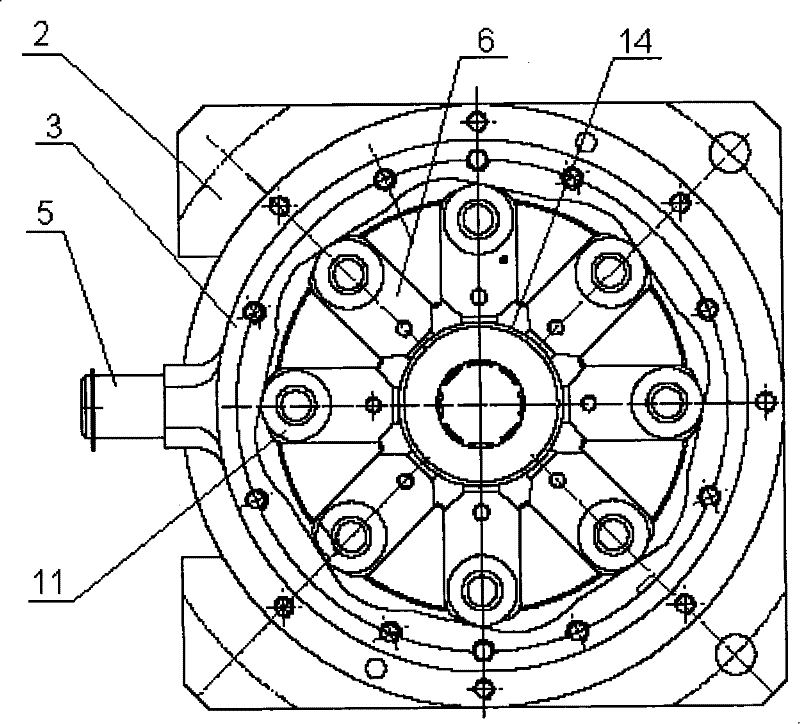

[0012] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises a housing 1, a base 2, a lower dial 3 and an upper dial 4 respectively having a central hole, and a toggle handle 5 is arranged on the outer ring of the lower dial 3, and radially Evenly have 8 (only take this as an example, not limited to this) long holes 6, lower dial 3 inner ring circumferential direction evenly have 8 (only take this as an example, not limited to this) chute, each A tight mouth slide block 7 is all installed in each chute, and is connected together with lower dial 3 by screw 8, and the front end of tight mouth slide block 7 replaceable tight mouth mold valve 9 is installed. The 4 circles of the upper dial are also evenly provided with 8 (only as an example, not limited to this) long holes 10 along the circumferential direction. Lower dial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com