Motor and its manufacturing process

A motor and power supply technology, applied in the field of motors, can solve problems such as poor assembly workability of motor housings, and achieve the effects of improving assembly operability, simplifying structure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

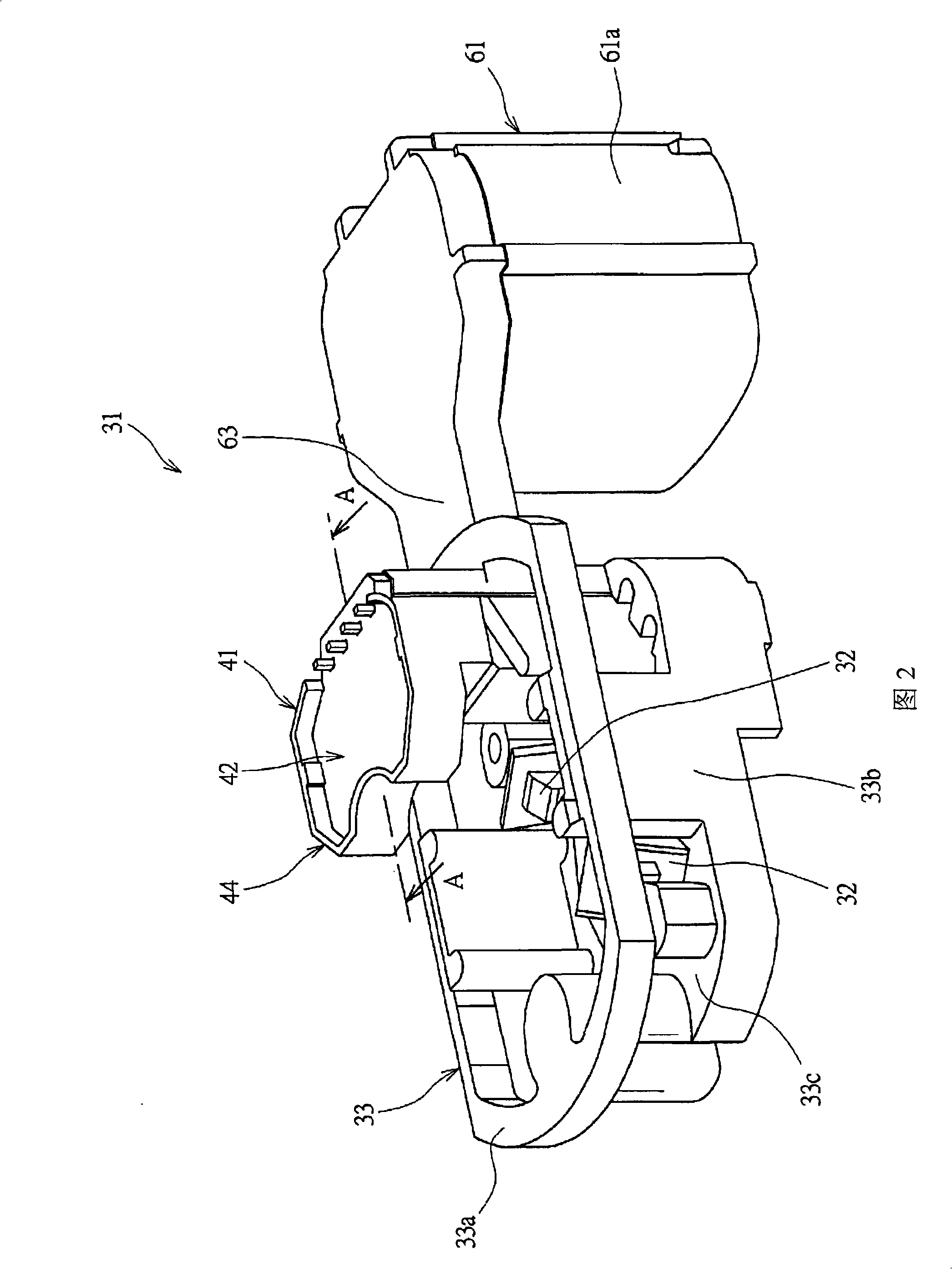

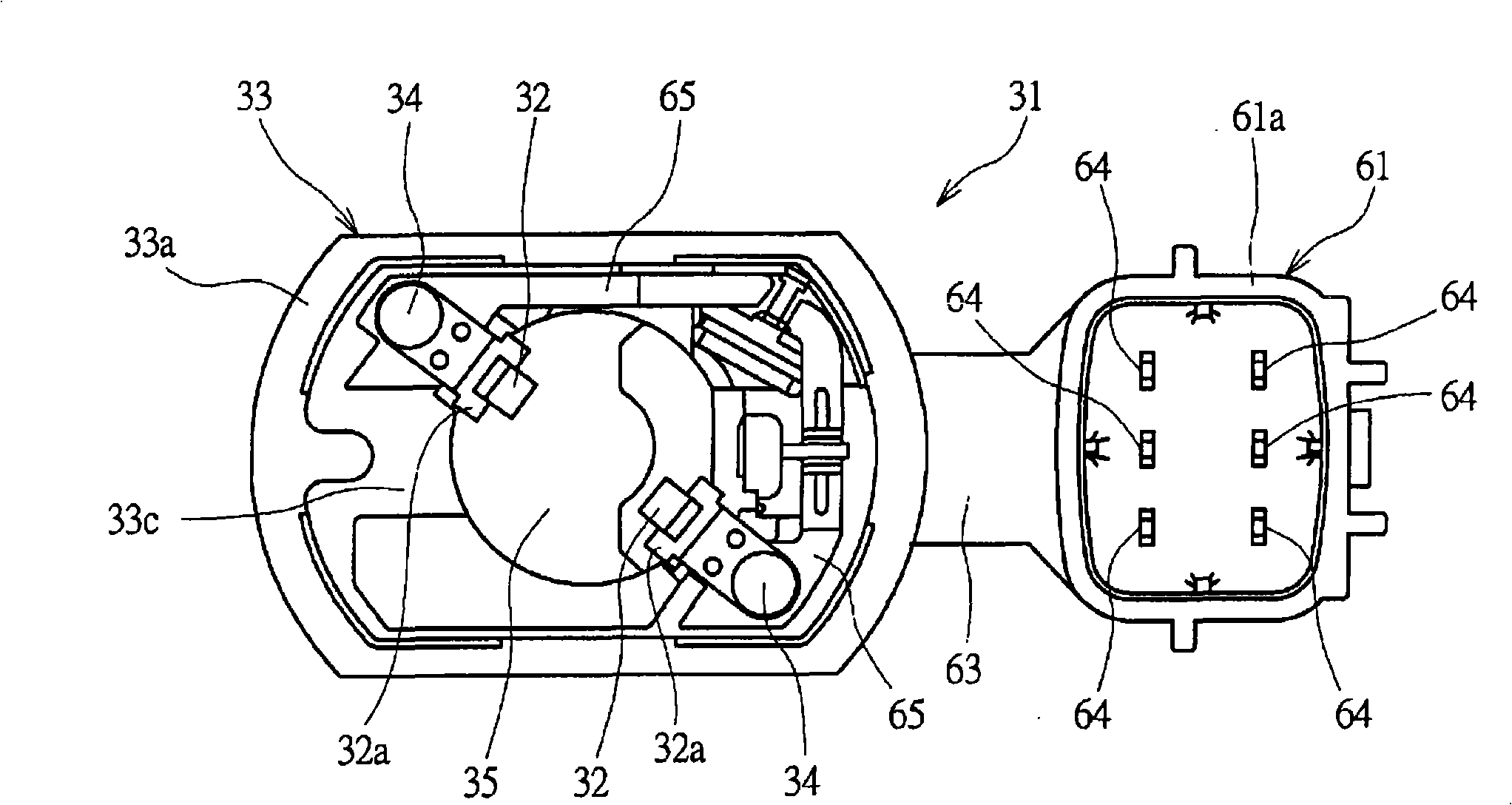

[0032] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

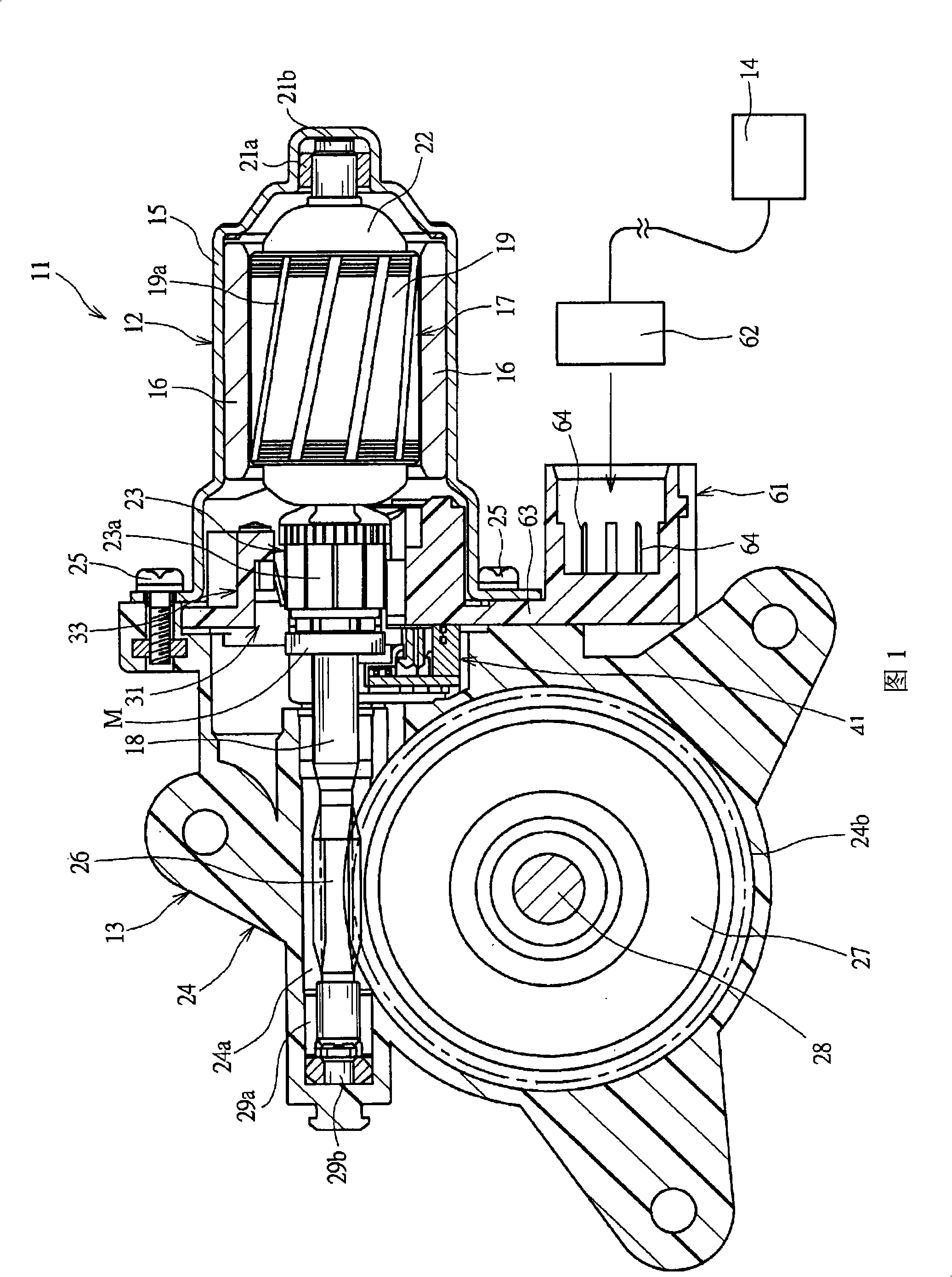

[0033] The automatic opening and closing type window motor 11 shown in FIG. 1 is a motor used as a driving source of an automatic opening and closing type window device of a vehicle not shown in the figure, and is an electric motor with a so-called speed reducer, that is, a motor that decelerates the The device 13 is installed on the motor body 12 and forms a unit. The control device 14 is provided on the automatic opening and closing type window device, the automatic opening and closing type window motor 11 is connected to the control device 14, and the operation of the automatic opening and closing type window motor 11 is controlled by the driving current supplied from the control device 14. Control is performed so that the window glass is automatically opened and closed.

[0034] The motor body 12 is a so-called DC motor with brushes. A pair of perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com