Display panel

A technology of display panel and non-display area, applied in static indicators, instruments, etc., can solve the problems of low bonding success rate, affecting bonding success rate, shape expansion and shrinkage, etc., to achieve the effect of high bonding accuracy and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

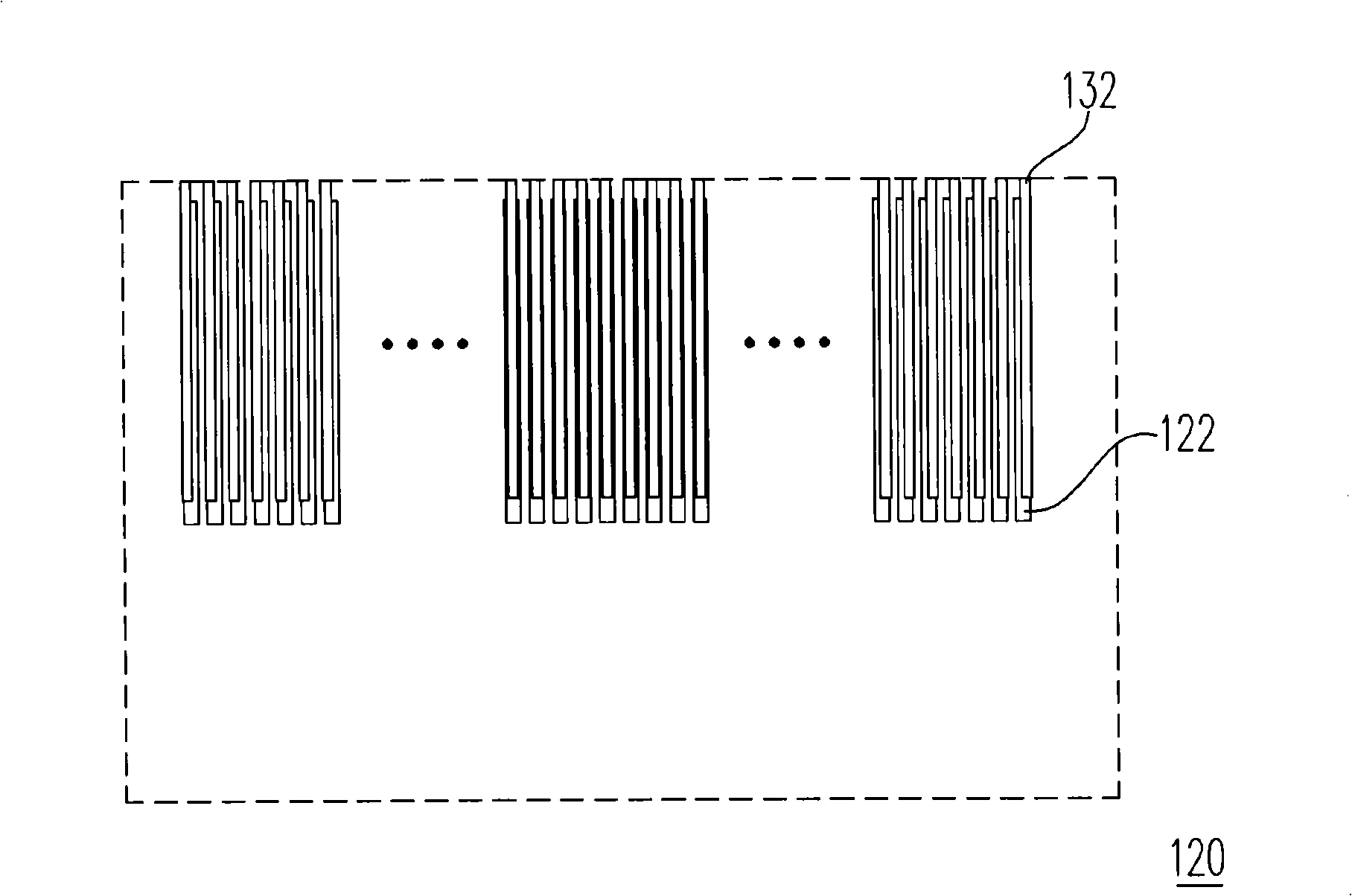

Image

Examples

no. 1 example

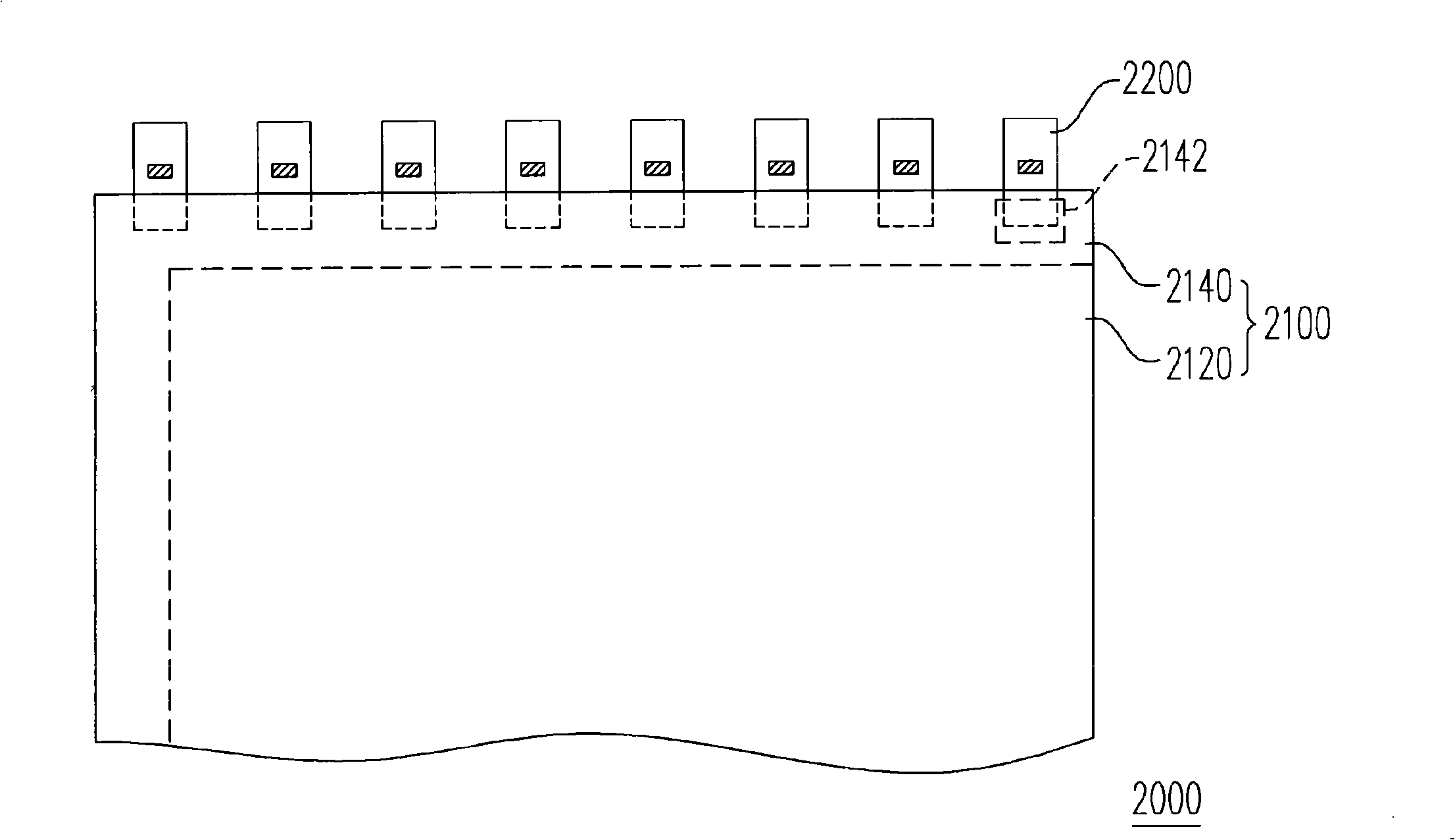

[0049] Figure 2A is a schematic diagram of the display panel of the first embodiment of the present invention, and Figure 2B for Figure 2A A partial enlarged view of the substrate of the display panel. Please also refer to Figure 2A and 2B , the display panel 2000 of this embodiment includes a substrate 2100 and a plurality of driving chips 2200 . The substrate 2100 of this embodiment is an active device array substrate, and the substrate 2100 has a display area 2120 and a non-display area 2140 , wherein the non-display area 2140 surrounds the display area 2120 . The pad area 2142 is located in the non-display area 2140, and the pad area 2142 has a central line 2142a. In addition, a plurality of first pins 2144 with the same length are arranged in each pad area 2142 , and these first pins 2144 are symmetrically arranged in parallel in the pad area 2142 with the center line 2142 a as the center.

[0050] It is worth noting that, in each pad area 2142 of the display pa...

no. 2 example

[0067] This embodiment is substantially the same as the first embodiment, and the reference numerals of elements similar to those of the first embodiment represent the same or similar elements, and will not be repeated here. Differences between this embodiment and the first embodiment will be described below.

[0068] image 3 It is a schematic diagram of bonding the first pins of the substrate to the second pins of the driving chip in the display panel according to the second embodiment of the present invention. Please refer to image 3 , the difference between this embodiment and the first embodiment is that: in each pad area 3142 of the display panel (not marked) in this embodiment, the width of the first pin 3144 will increase as it is in the pad area 3142 The location of the configuration within varies. In detail, the first pins 3144 are disposed from the center line 3142 a of the pad area 3142 to the outside, and the width of the first pins 3144 may gradually become w...

no. 3 example

[0072] This embodiment is substantially the same as the first and second embodiments, and similar reference numerals represent the same or similar components, and will not be repeated here. Figure 4 It is a schematic diagram of bonding the first pins of the substrate to the second pins of the driving chip in the display panel according to the third embodiment of the present invention. Please refer to Figure 4 The difference between this embodiment and the first and second embodiments lies in: in each pad area 4142 of the display panel (not marked) of this embodiment, the distance between two adjacent first pins 4144, and The width of each first pin 4144 varies according to its position in the pad area 4142 . In detail, the first pins 4144 are arranged outside the center line 4142a of the pad area 4142, the width of the first pins 4144 gradually increases, and the distance between two adjacent first pins 4144 gradually widens. .

[0073] In this way, the traditional proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com