Geological advanced prediction method suitable for TBM construction

A geological advanced forecasting and working face technology, applied in seismology, geophysical measurement, measuring devices, etc., can solve the problems of complex installation of testing equipment, unsatisfactory forecasting results, interference of electrical testing, etc., to achieve on-site data collection and Rapid analysis, high accuracy, and good forecasting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This embodiment takes the test of the 26+054 working face of the TBM1 bid section in the water delivery tunnel of the Dahuofang Reservoir as an example. The scope of this forecast: 100 meters in front of the 26+054 working face (corresponding to the mileage 26+054~26+154).

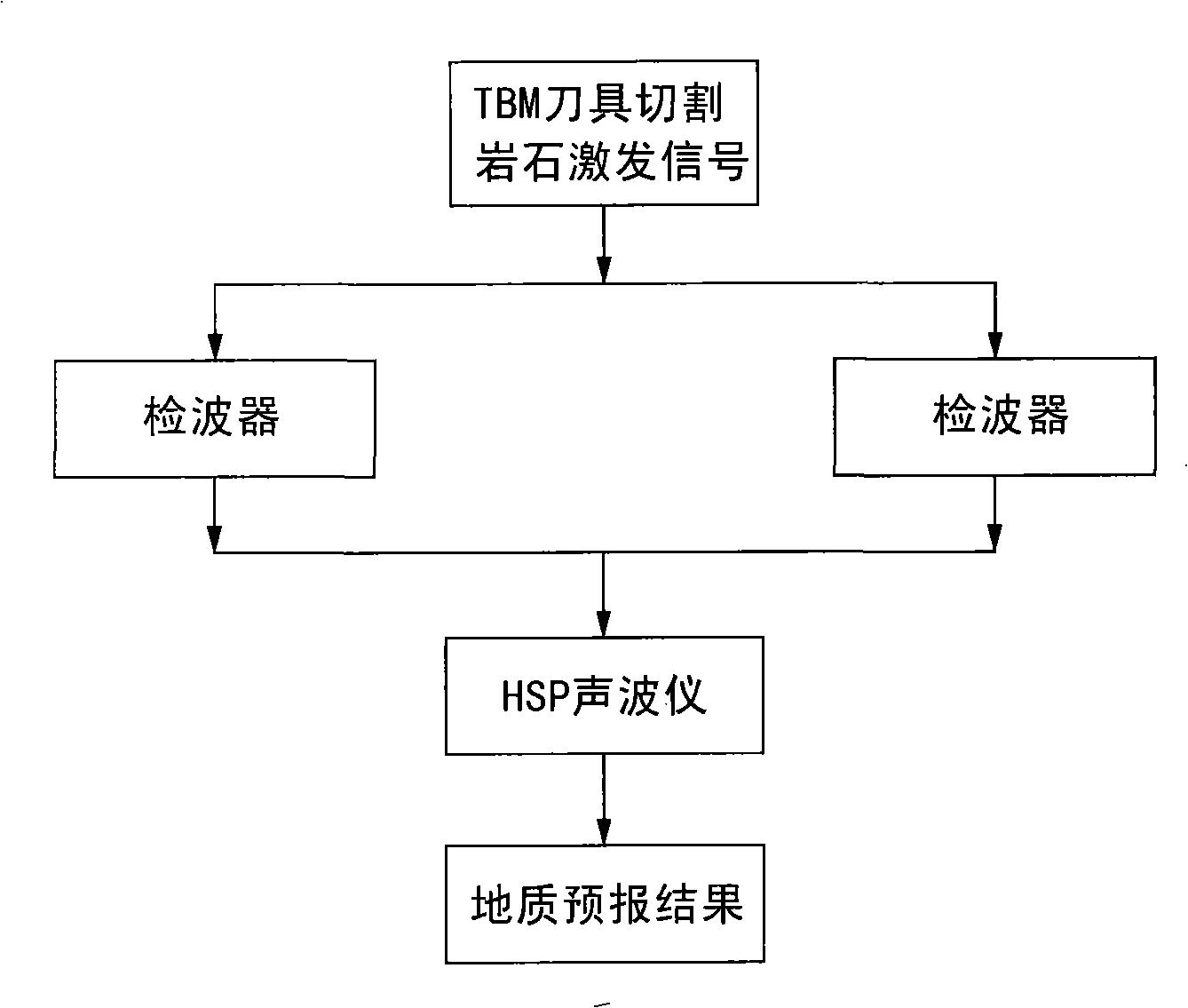

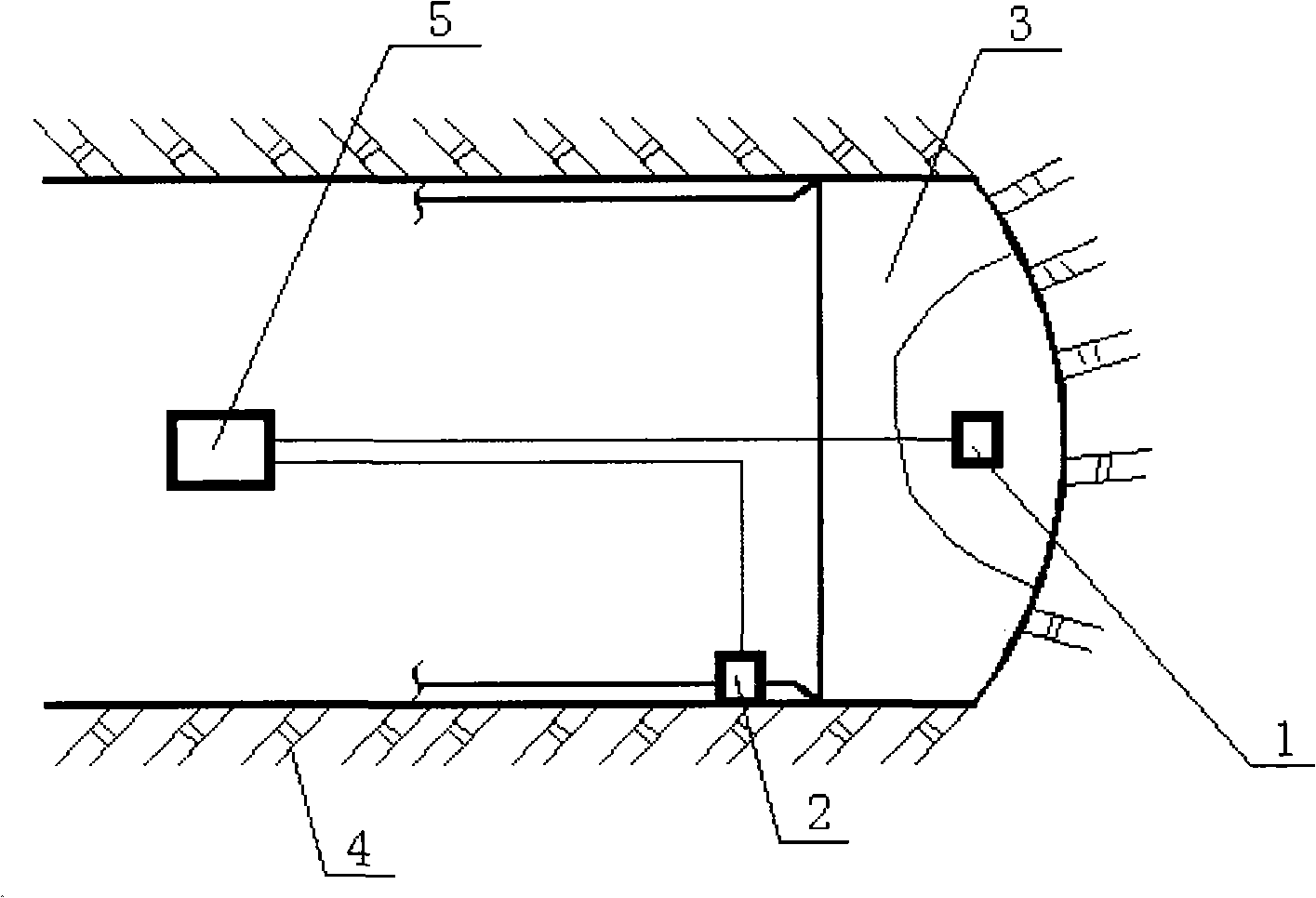

[0022] see figure 1 , figure 2 .

[0023] (1), a synchronous signal detector 1 for synchronously receiving the acoustic wave signal excited by the TBM cutter cutting rock is installed inside the cutter head 3 of the TBM, and installed in the side arch waist surrounding rock 4 located at the rear of the TBM working face A signal detector 2 is used to receive the reflected wave signal transmitted from the front of the TBM working face through the rock mass. The specific position of the detector 2 is based on the ability to receive effective reflected wave signals, and there is no strict distance limit. Geophone 1 and geophone 2 are commercially available conventional geophones with a model of 50-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com