Plate blank movable turn-over device

A turning device and slab technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of improving the production quality of high-quality oriented silicon steel sheets, so as to solve the bottleneck of production quality, ensure stability and yield Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

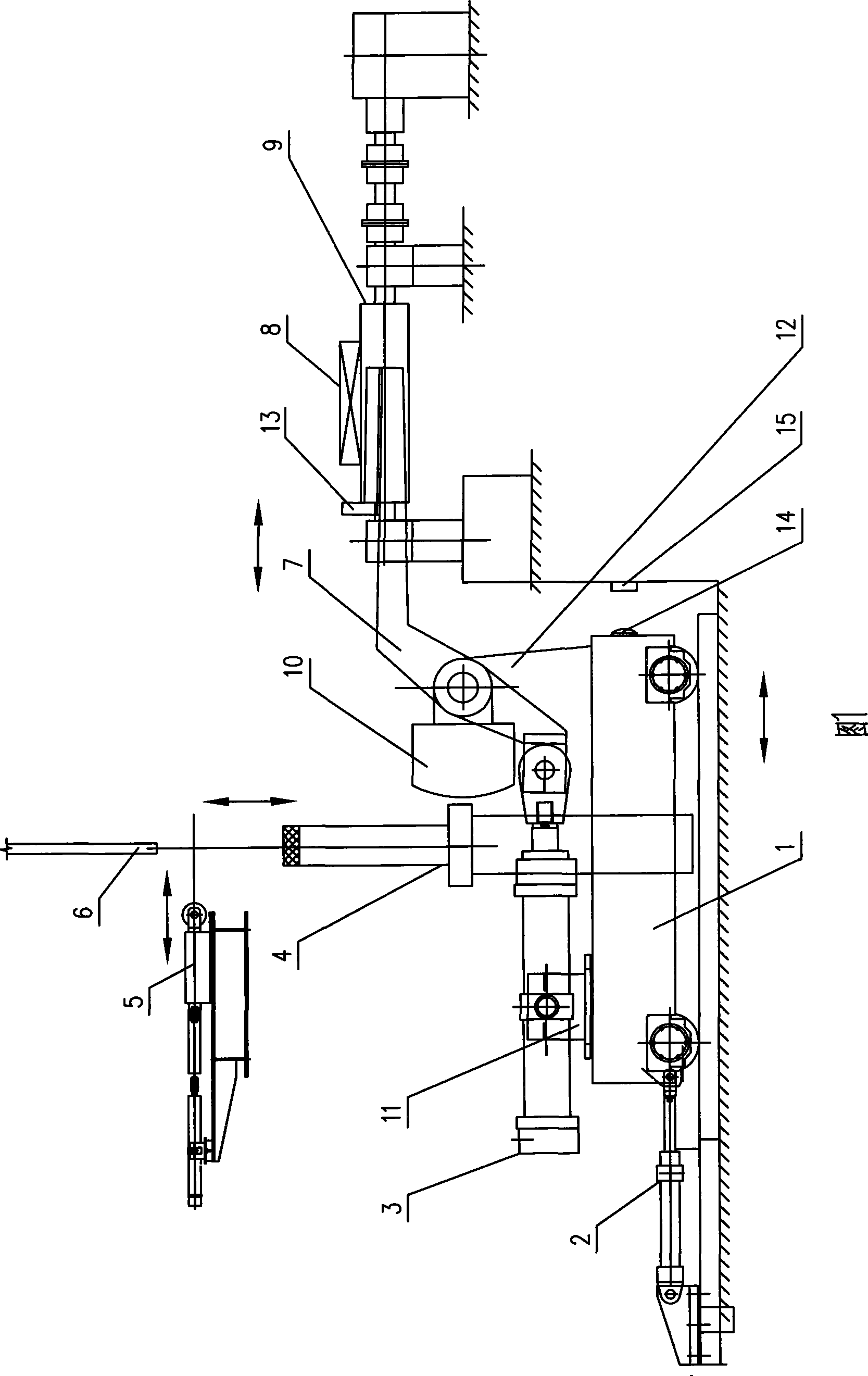

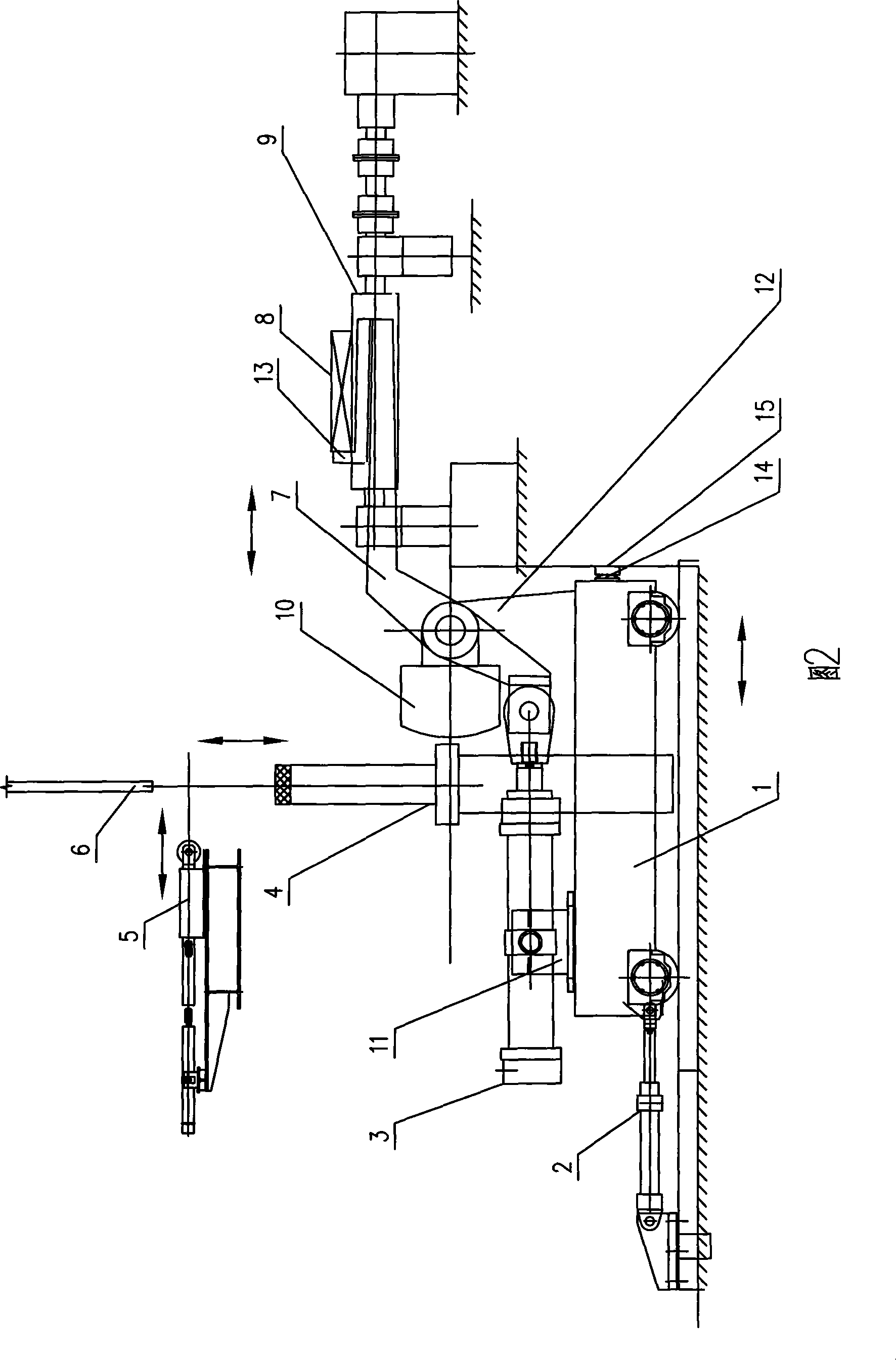

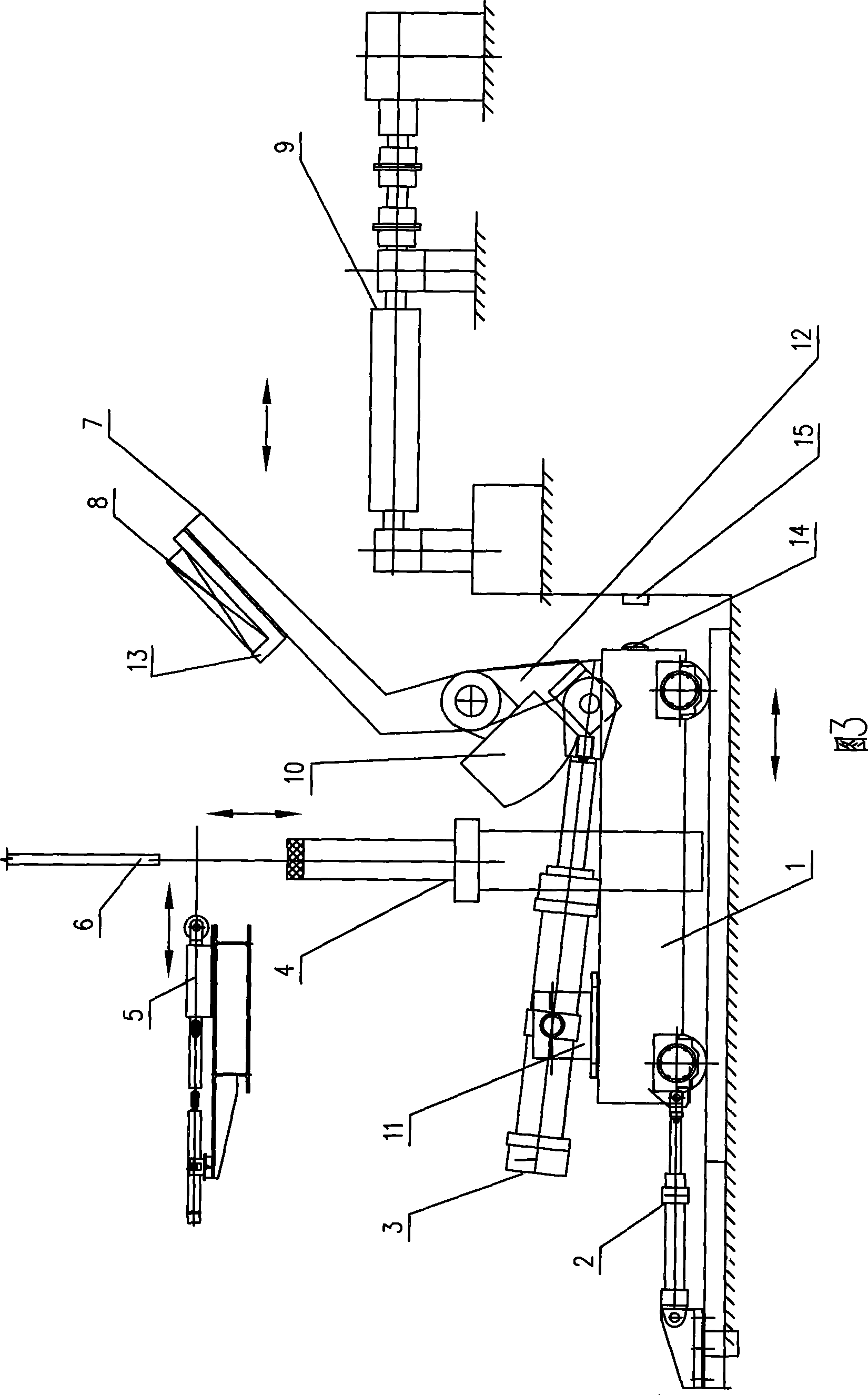

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0015] The slab moving and turning device shown in the figure includes a horizontal moving trolley 1 arranged on the flanks of the slab roller table 9 and positioned on the track below the slab heating furnace 4 . A horizontal oil cylinder 2 is fixedly installed on the track at the rear end of the horizontal moving trolley 1, and the piston rod end of the horizontal oil cylinder 2 is hingedly connected with the horizontal moving trolley 1 to control the movement of the horizontal moving trolley 1 between the slab heating furnace 4 and the slab roller table 9. Move back and forth between.

[0016] On the rear body of the horizontally moving dolly 1 away from the slab roller table 9, an overturning oil cylinder fixed support 11 is fixedly installed, and the cylinder body of the overturned oil cylinder 3 is hinged on the overturned oil cylinder fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com