Method and equipment for hot rolled plate colored forming continuous production

A technology for hot-rolled sheets and hot-rolled steel sheets, which is applied in the fields of color coating production and forming sheet production, can solve the problems of complex intermediate conveying links, inability to operate continuously, and occupy a large area, so as to save the amount of paint and reduce energy. Waste and reduce the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

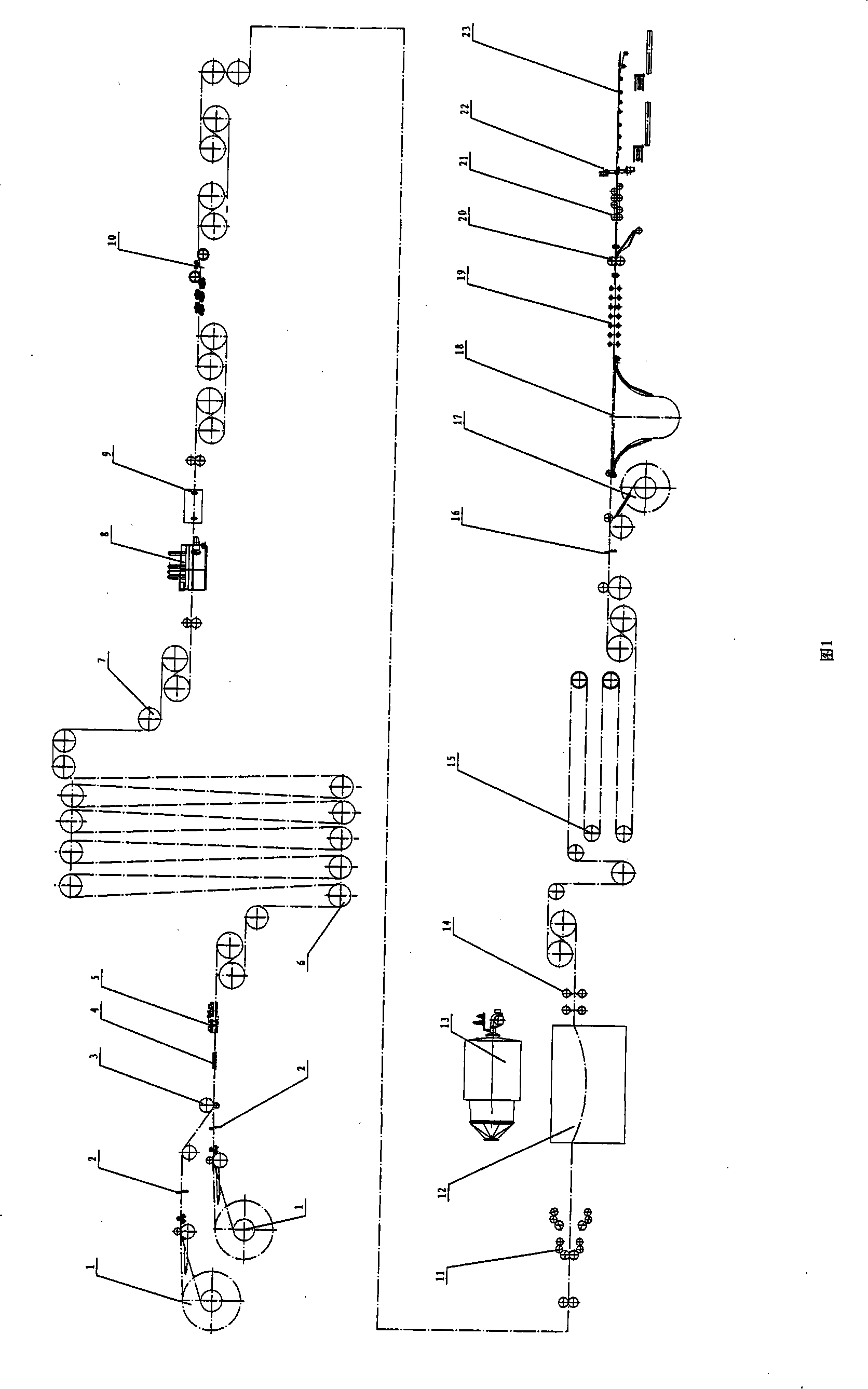

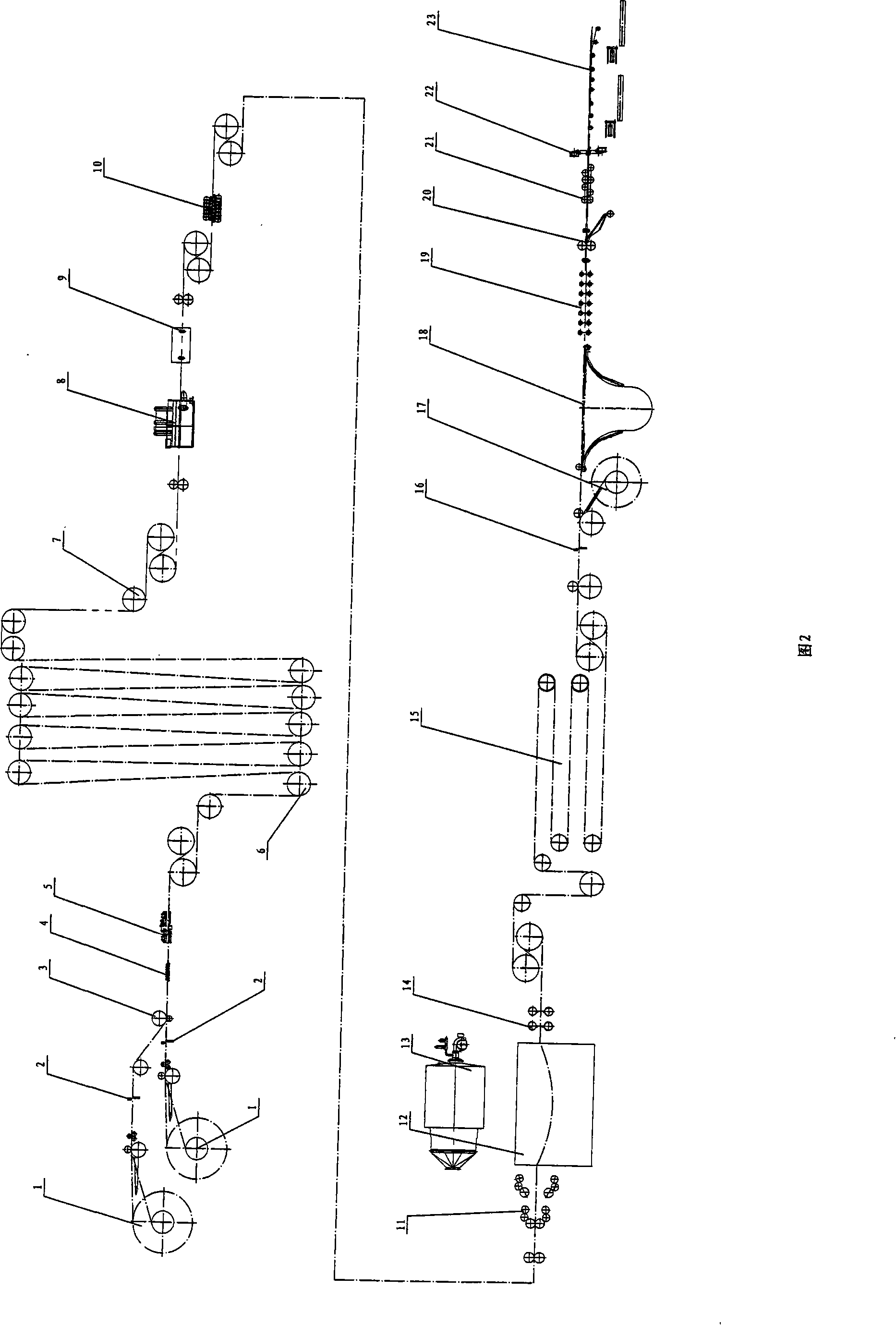

[0019] Entrance section: put the steel coil on the uncoiler 1 with a steel coil car, use double uncoilers 1, uncoil in turn, save feeding time, flatten the plate head with a straight head machine, and cut off the headband with a shearing machine 2 The tail is sent to the leveler 4 through the converging pinch roller 3. The tail of the previous steel coil and the head of the next steel coil are merged and welded at the welding machine 5. The steel strip enters the vertical looper 6 and is uncoiled normally. When the material is stored, the vertical looper 6 stores the material, and when the coil is changed and welded, the vertical looper 6 discharges the material, which meets the requirements of continuous production of the unit;

[0020] Process section: the steel strip turns to the centering roller 7, and after the deviation is corrected, it enters the pickling section 8. At this stage, the steel strip is pickled to remove the oxide scale on the surface of the steel strip, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com