Generator

A generator and electric power technology, applied in the direction of unipolar motors, electrical components, electromechanical devices, etc., can solve the problems of reduced rotational force of the rotor plate, reduced power generation efficiency, and power extraction, and achieve the effect of preventing the reduction of rotational force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

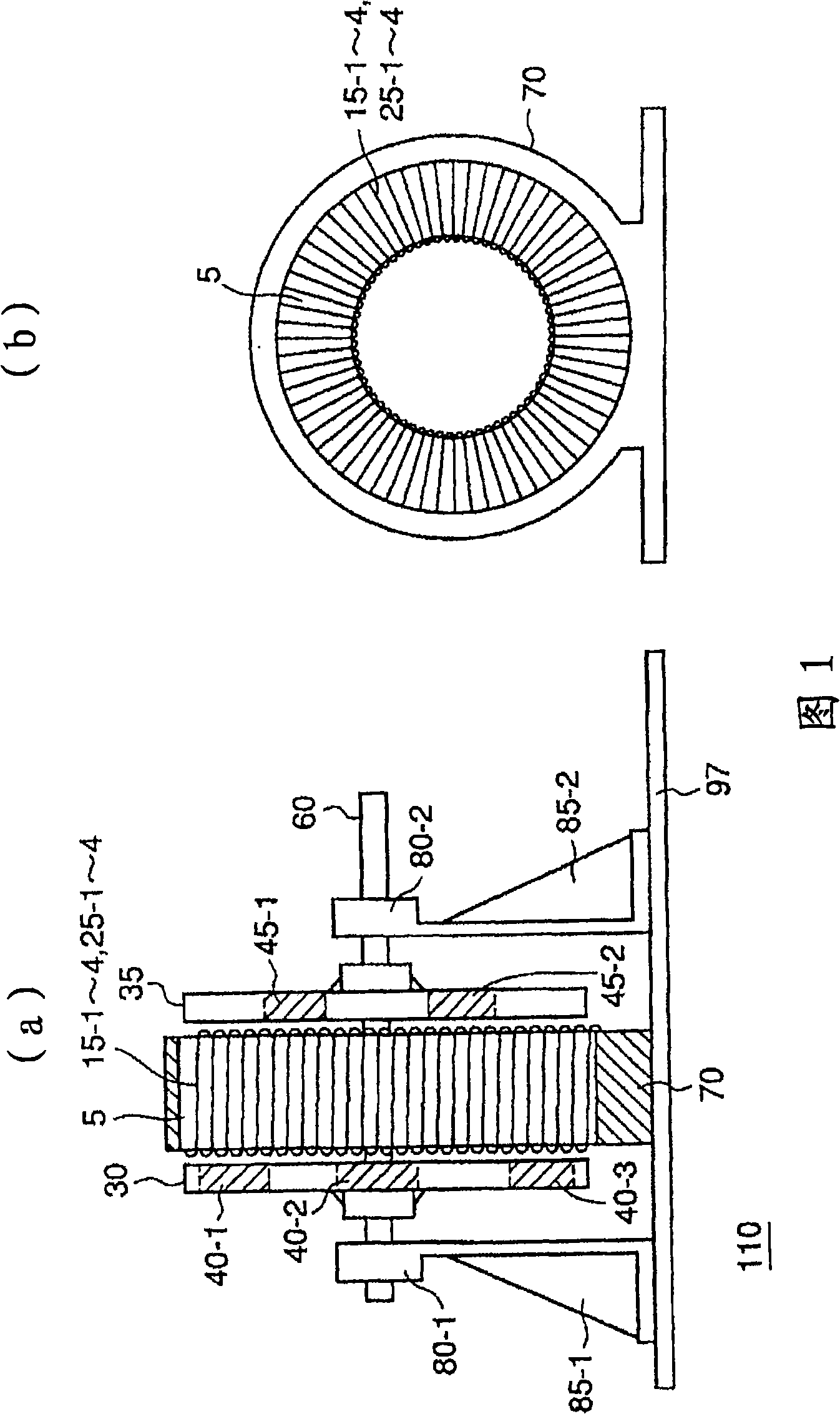

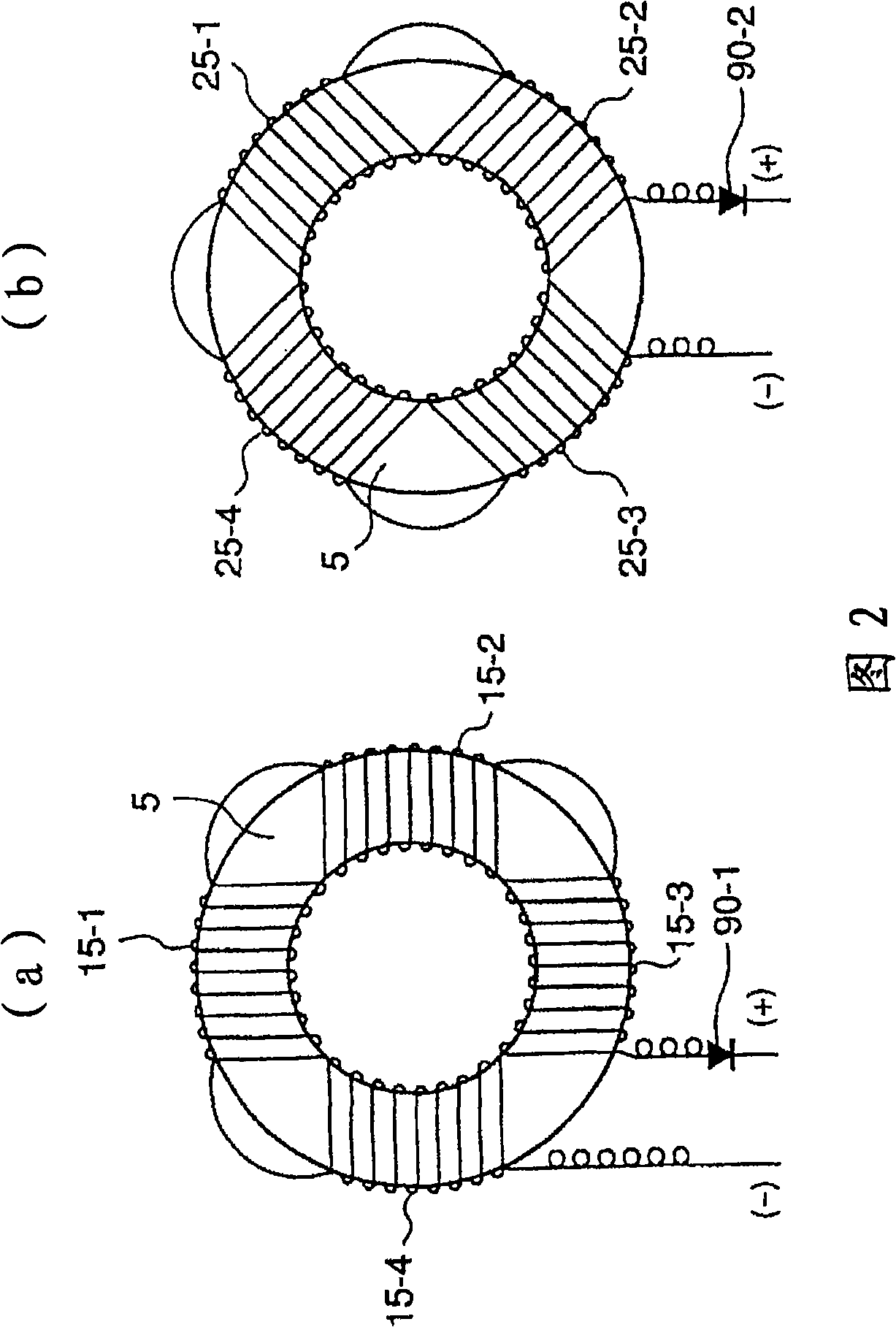

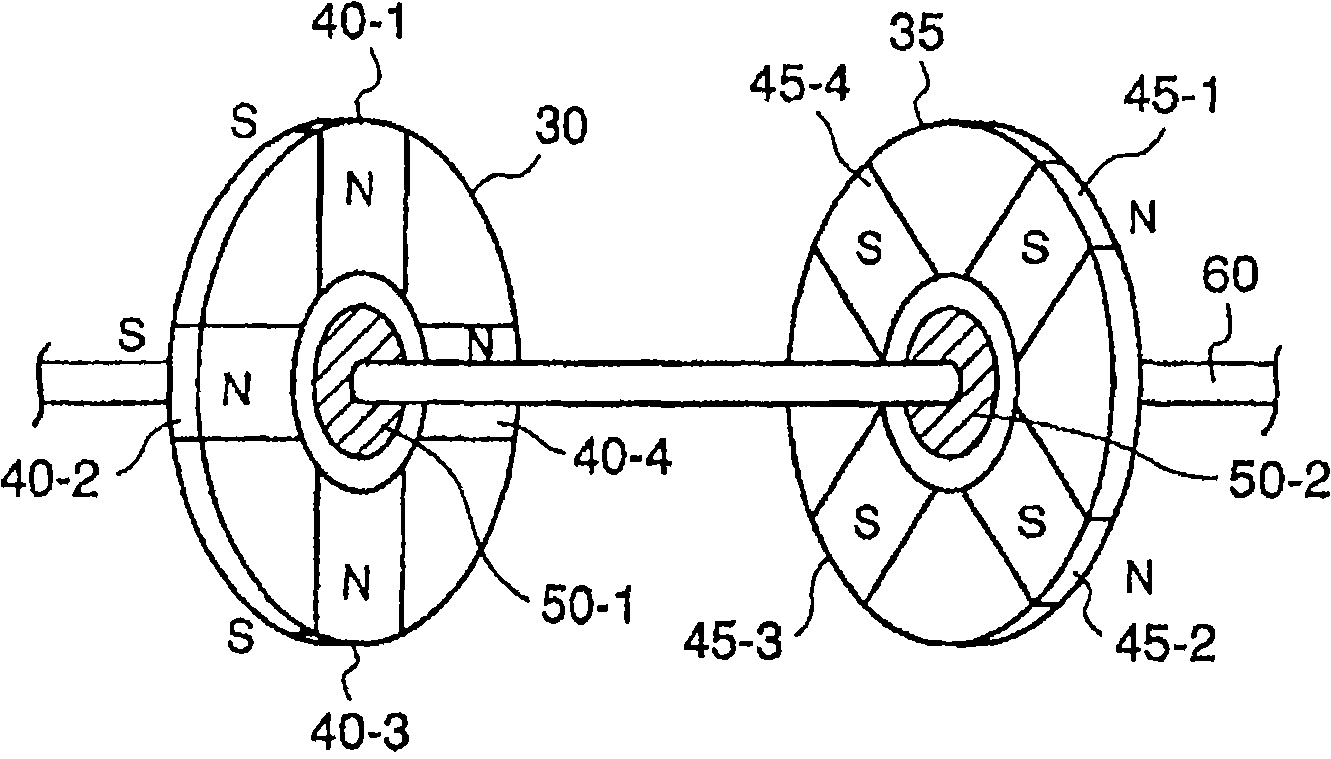

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a configuration diagram showing the configuration of a generator according to the present invention. In (a) of FIG. 1, the stator 70 of the generator 110 is fixed on the base 97, and the annular core 5 is installed on the On the stator 70. The first rotor plate 30 and the second rotor plate 35 are arranged on bearings 80-1, 80-2 respectively having supporting plates 85-1, 85-2 through the drive shaft 60, and the bearings 80-1, 80-2 are fixed on on the base 97. In addition, the first rotor plate 30 and the second rotor plate 35 have first permanent magnets 40-1 to 4 and second permanent magnets 45-1 to 4, respectively. The drive shaft 60 receives a rotational drive torque (not shown) from the outside to rotate the first rotor plate 30 and the second rotor plate 35 to generate a rotating magnetic field.

[0024] In (b) of FIG. 1 , the annular core 5 on which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com