Switching device with spring device for a change speed gearbox

A technology of shifting device and spring device, applied to components with teeth, transmission device control, belt/chain/gear, etc., which can solve the deviation of bolt manufacturing tolerances from each other, the existence of play, and the inaccurate positioning of the main shift shaft And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] figure 1 A typical shift diagram of a manual selector lever for shifting a manual transmission with six forward gears I to VI and one reverse gear R is shown. The forward gears I, II are located in the first shift gate 1 here. Correspondingly, the forward gears III and IV can be allocated to the second shift slot 2 , and the forward gears V and VI can be allocated to the third shift slot 3 . The reverse gear R can be reached via the shift gate 4 . The shift gates 1 , 2 , 3 , 4 are connected to each other by a selector gate 5 . The neutral position N is located in the intersection of the selector gate 5 and the shift gate 2 between the forward gears III, IV. A restoring force acts on the manual selector lever along the selector gate 5 , so that it can slide into the neutral position N as long as no force is applied from the outside.

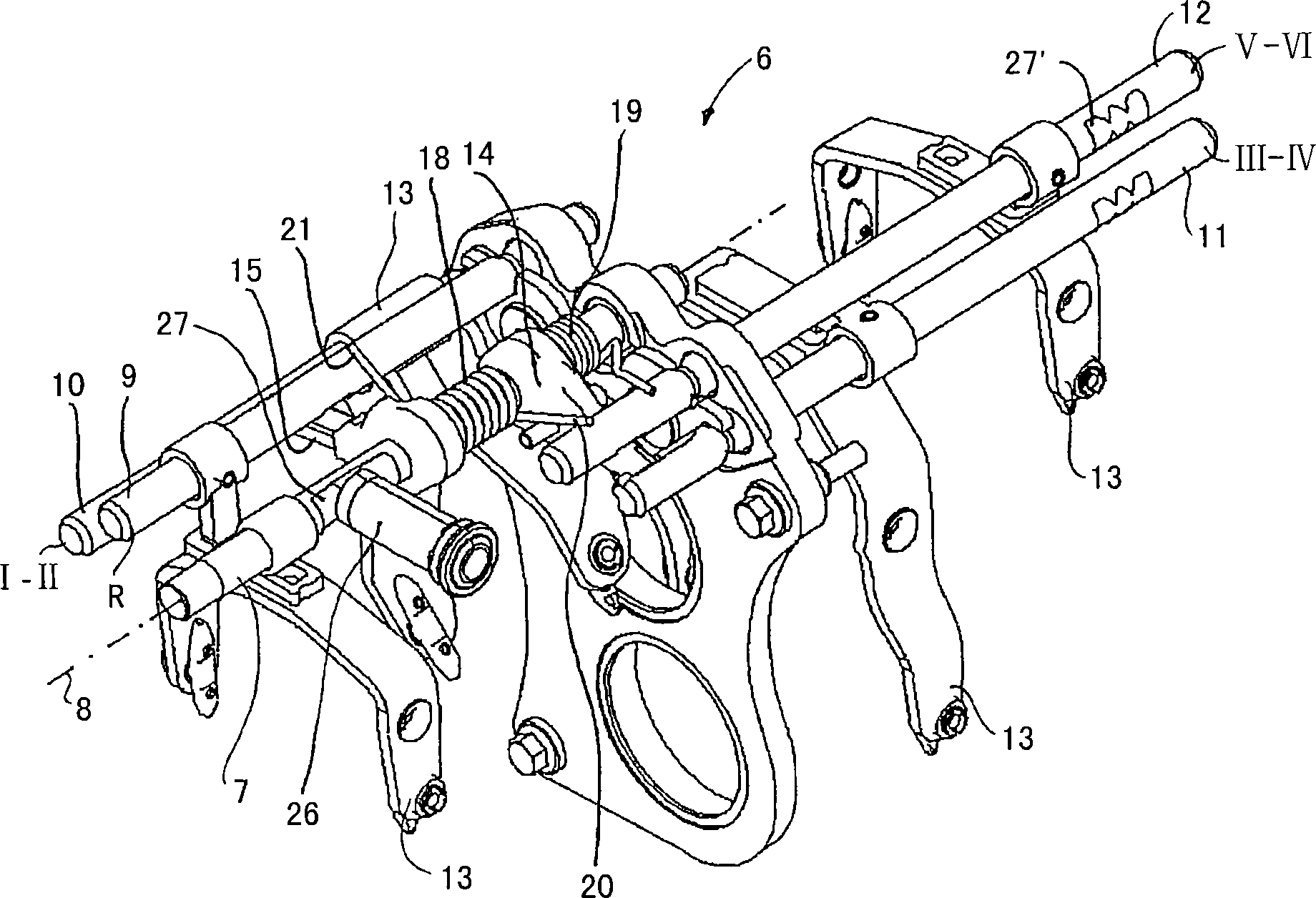

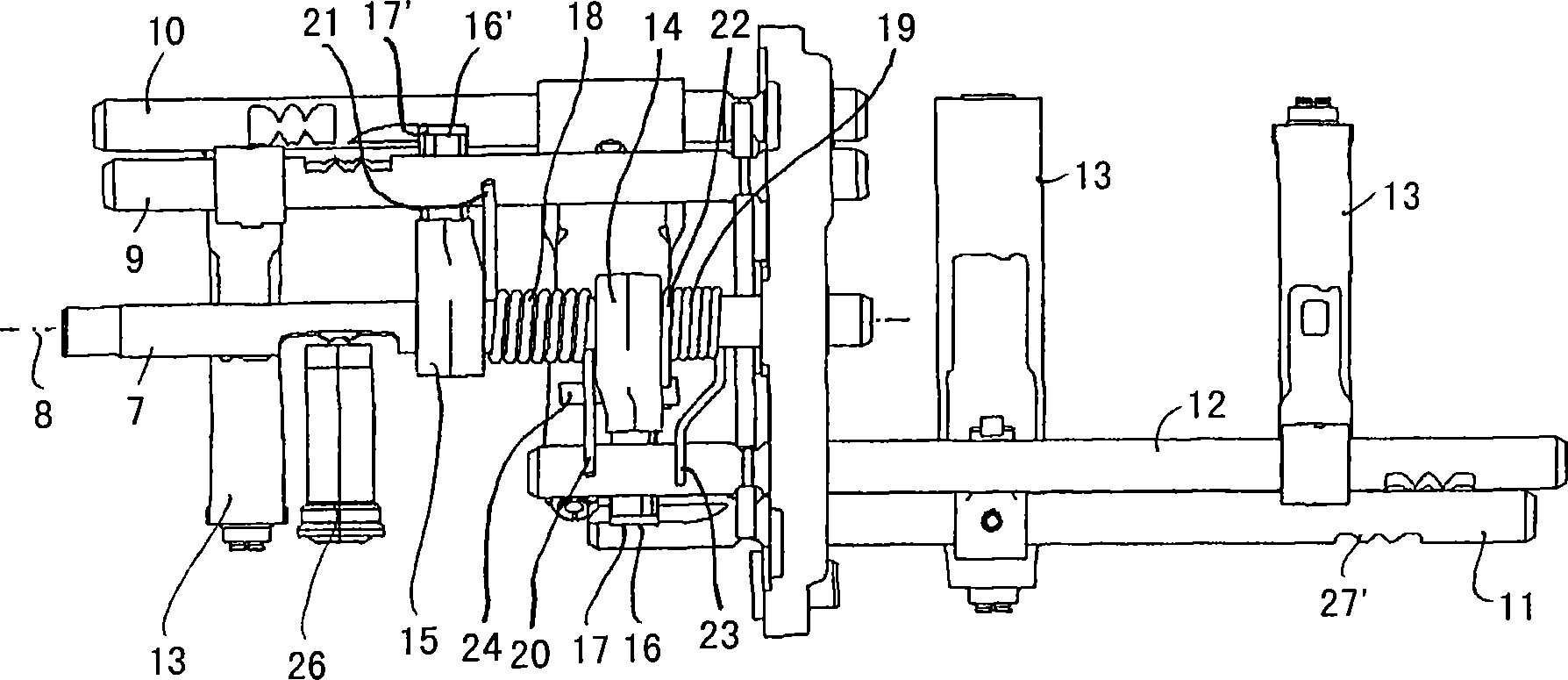

[0031] figure 1 The shift diagram shown in the figure 2 Corresponds to the shifting device 6 shown in FIG. 7 . figure 2 FIG. 7 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com