Two-part oil scraper ring for internal combustion engines

A technology for oil scraping rings and internal combustion engines, applied to piston rings, mechanical equipment, engine components, etc., can solve problems such as insufficient oil scraping effect and structural height that can no longer be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

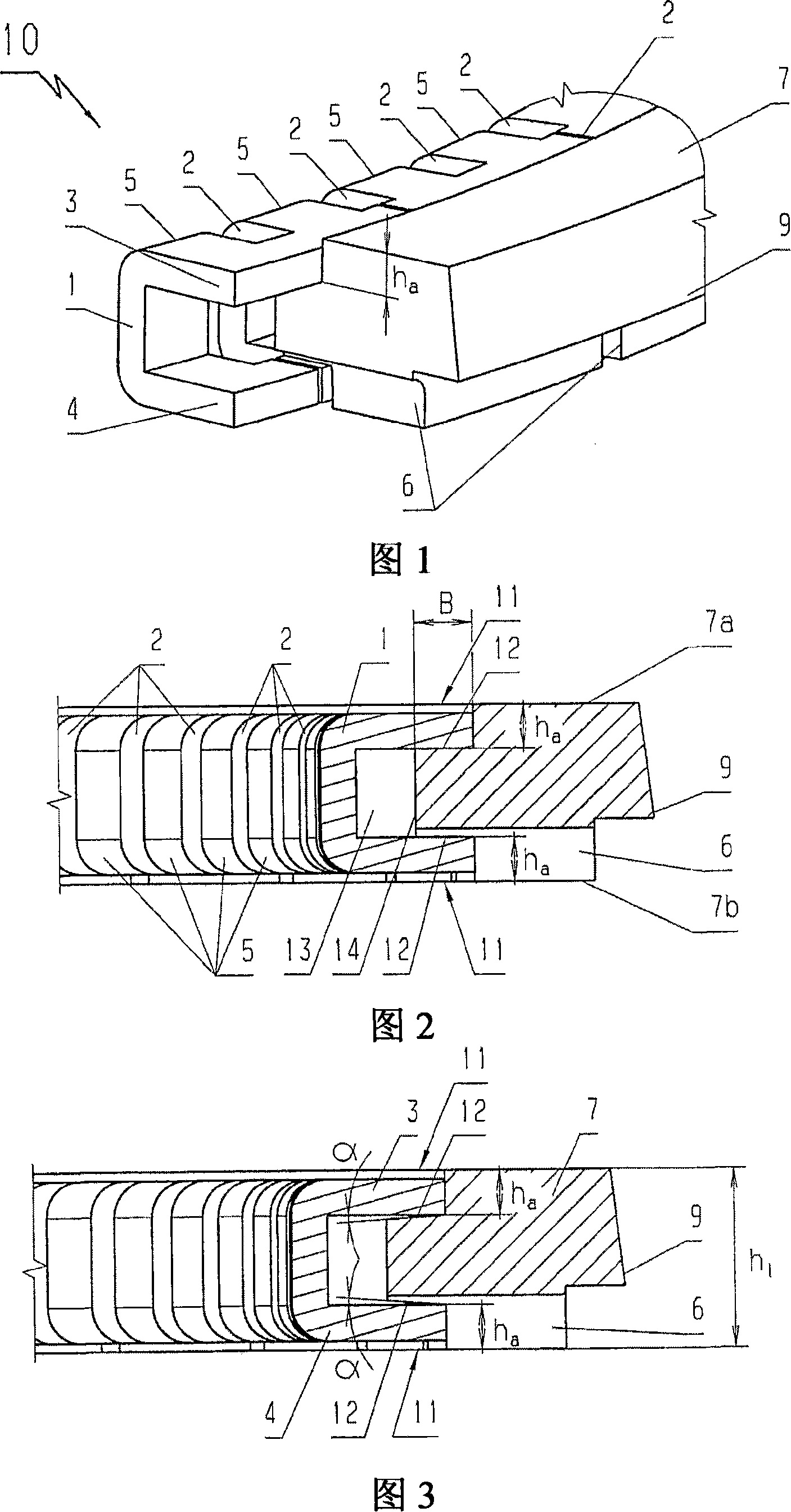

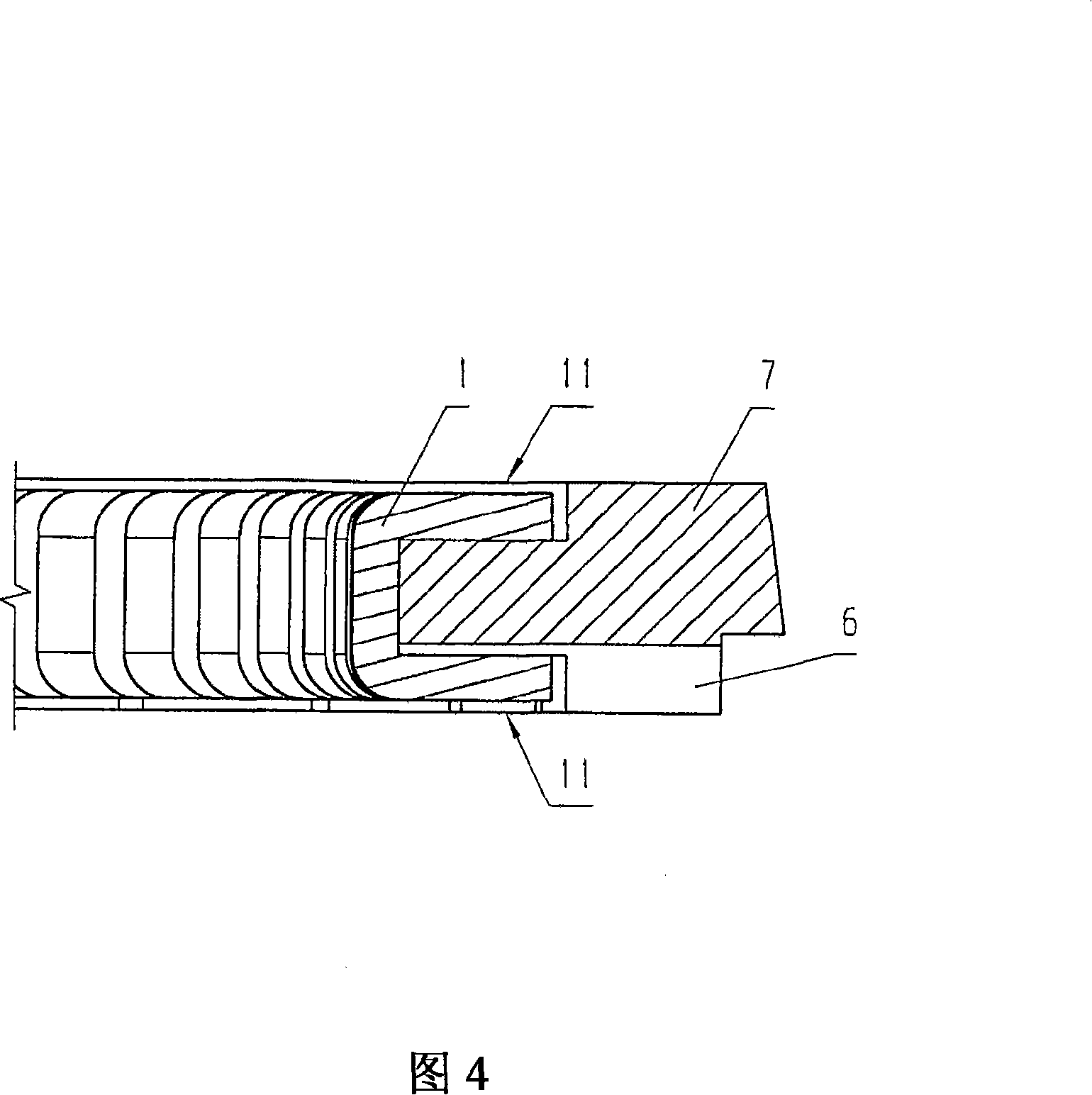

[0011] As can be seen from the perspective view of FIG. 1 , the oil wiper ring 10 according to the invention consists of an expanded spring ring 1 with a U-shaped cross-section, the ring body being arranged between elastic legs 3 and 4 pointing radially outwards of the expanded spring ring. 7. The ring body has a working surface 9. The expansion spring ring 1 has a cutout 2 on its radial inner side, so that the spring legs 3 and 4 are connected to one another via a web 5 designed as the back of the spring ring. Via these cutouts 2 the expansion spring ring 1 is designed elastically in the circumferential direction.

[0012] The ring body 7 , which can be designed as a nose-shaped conical ring, consists of steel or cast iron, and has sides 7 a and 7 b that are parallel to each other. These sides have a roughness of Rz<2 μm for steel ring bodies and Rz<4 μm for cast iron ring bodies. According to FIGS. 2 and 3 , the ring body 7 has at its radially inner end, that is to say in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com