Tension bolt for compressor

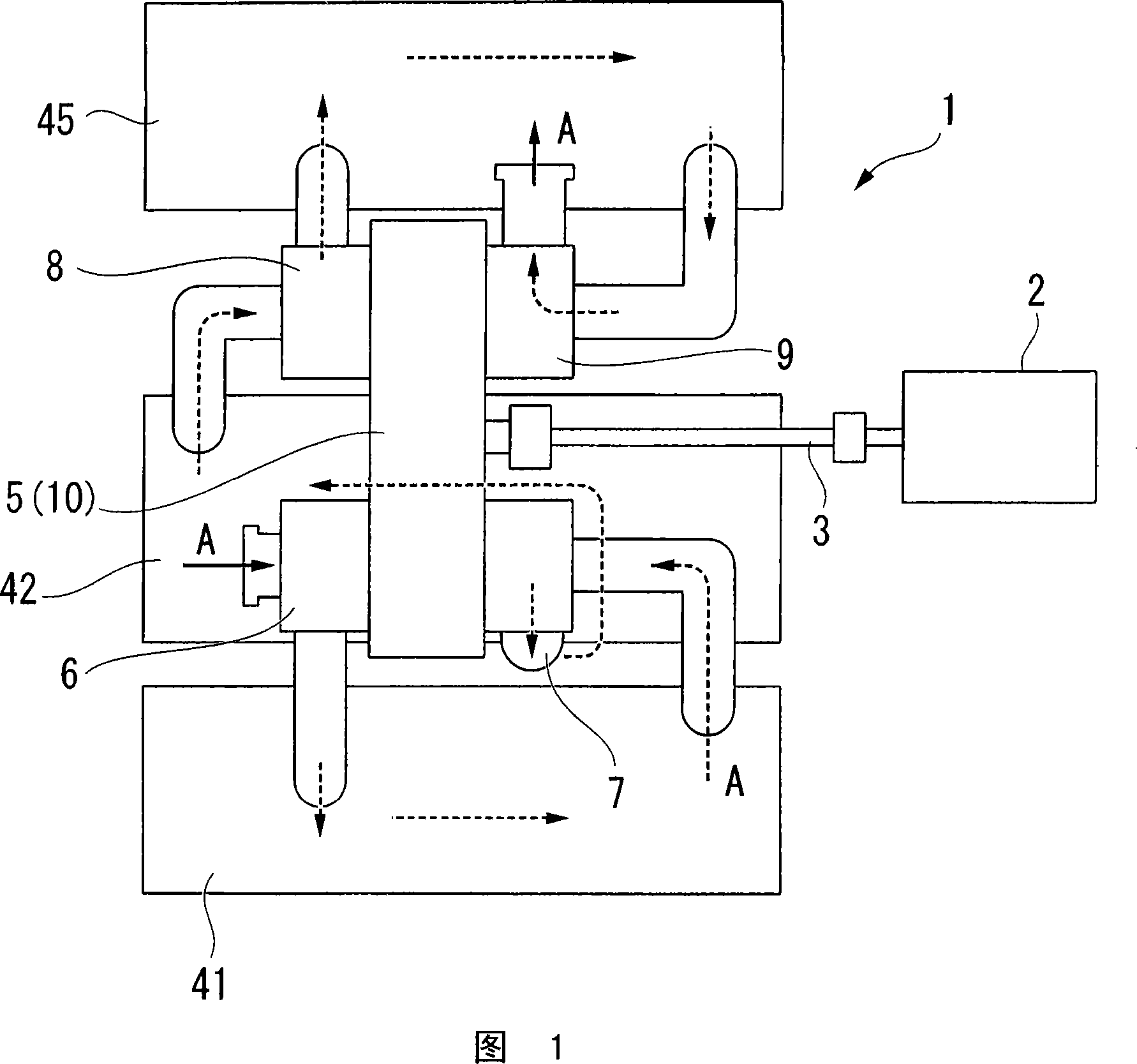

A technology for tightening bolts and turbo compressors, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as low operating efficiency and small elongation of tightening bolts, and achieve improved workability and dangerous speed. It does not reduce the effect of simplifying the adjustment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

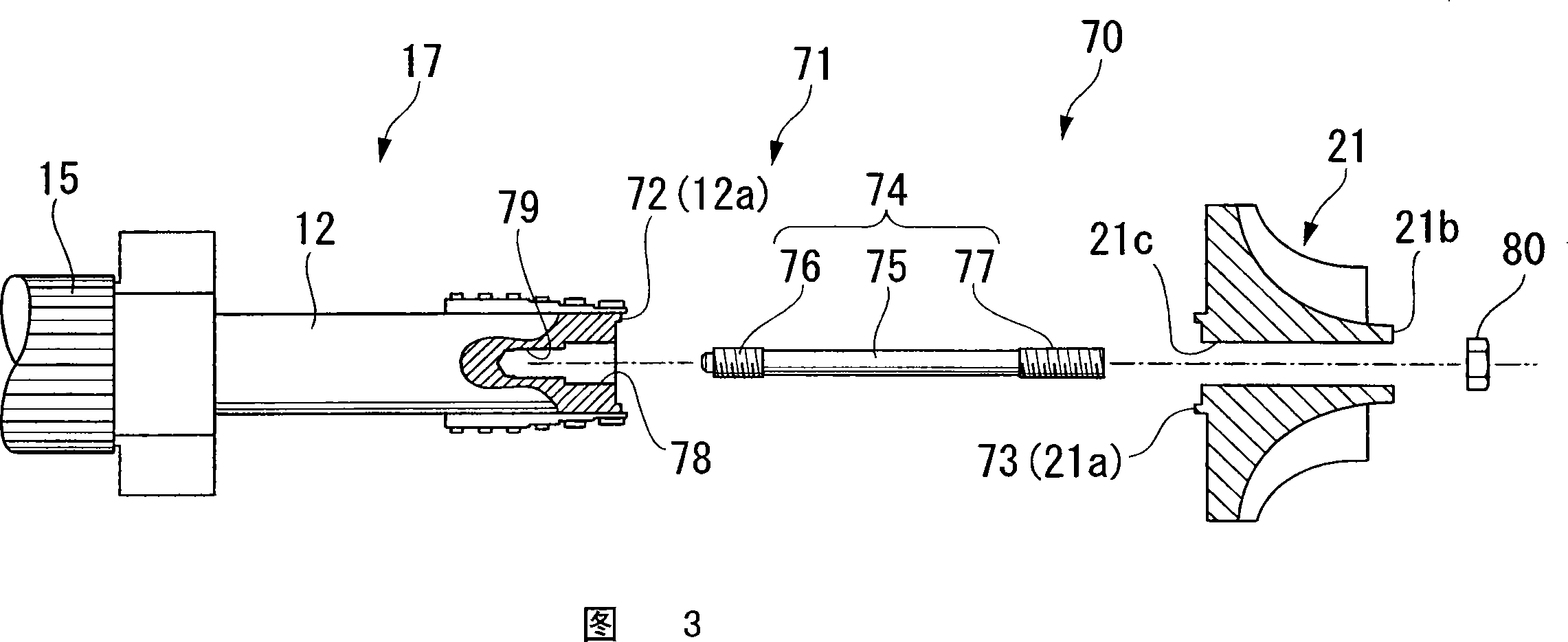

[0087] 6A is a cross-sectional view of the fastening mechanism 90 of the second embodiment, and FIG. 6B is a cross-sectional view of the first impeller 21.

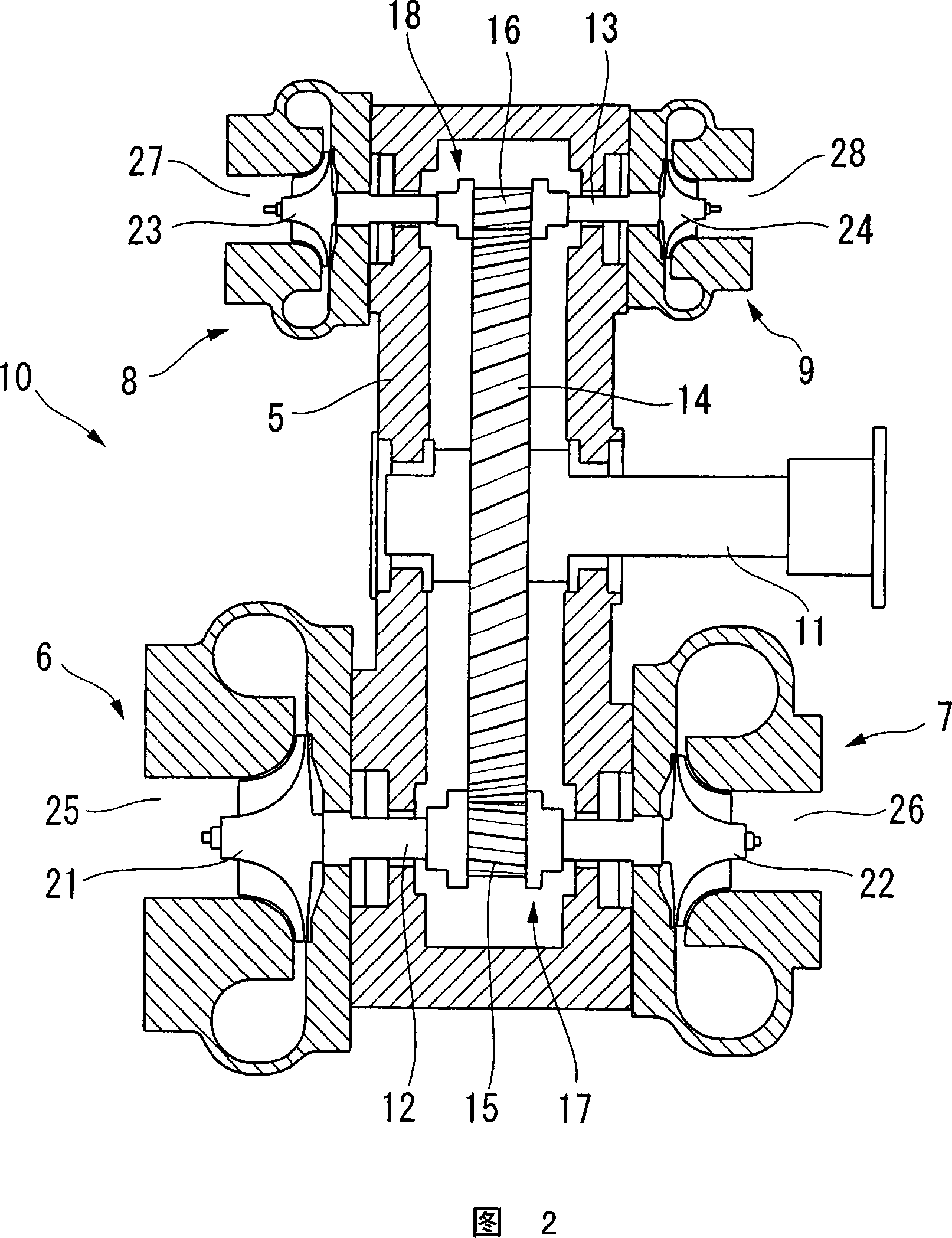

[0088] As with the fastening mechanism 70 of the first embodiment, the fastening mechanism 90 fastens both ends of the second rotating shaft 12 to the first impeller 21 and the second impeller 22.

[0089] Hereinafter, only the parts different from the fastening mechanism 70 of the first embodiment will be described, and the same parts are denoted by the same reference numerals, and the description thereof will be omitted.

[0090] The fastening mechanism 90 includes: a curved tooth coupling 71, which fastens the second rotating shaft 12 and the first impeller 21 in a consistent manner with their respective rotating shaft cores; and a tension bolt 74, which clamps and presses at a predetermined pressure Support the second rotating shaft 12 and the first impeller 21; tighten the nut 80 and so on.

[0091]The arc tooth coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com