Differential arrangement with assembly openings

A differential and assembly technology, which is applied in the field of motor vehicle transmission system, can solve the problems of uneven distribution and imbalance of the mass of the differential frame, reduce the stiffness and strength of the differential frame, and achieve light weight , high rotational stiffness, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

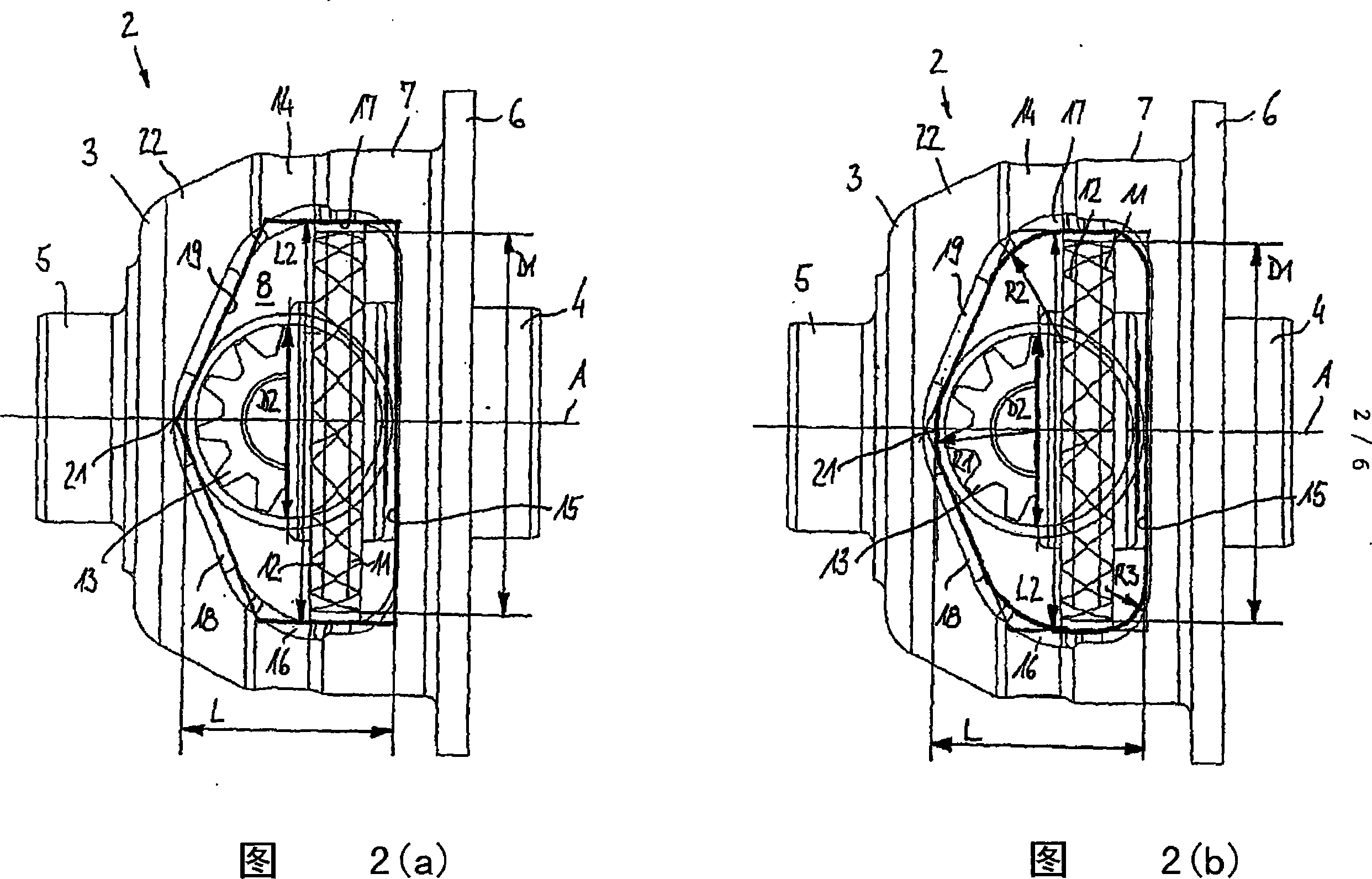

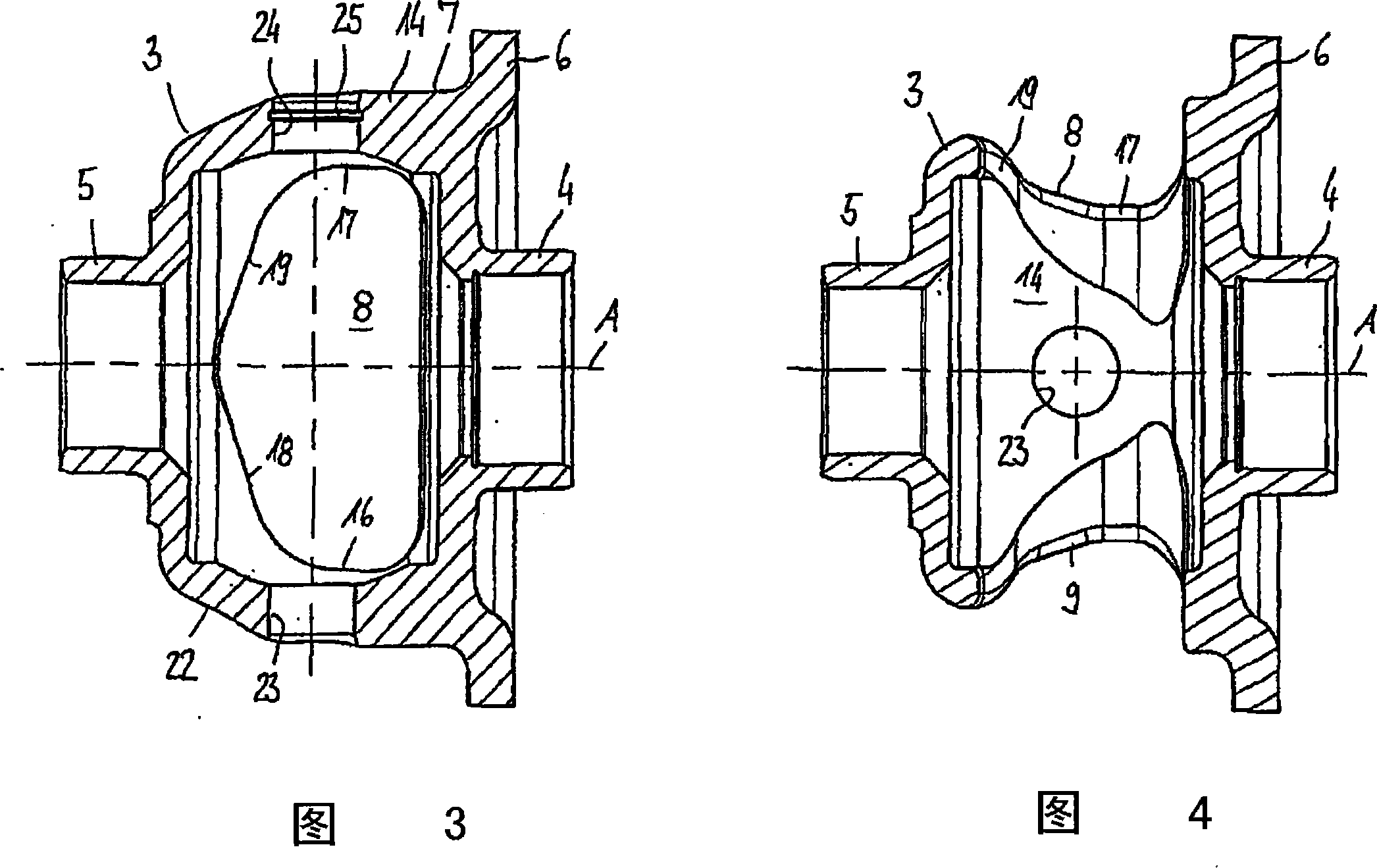

[0030]The differential assemblies 2 shown in FIGS. 1 and 2 substantially correspond to each other in terms of their design and mode of function and will therefore be described jointly below. The same components have the same reference numerals. The figure shows a differential assembly 2 with an integral differential carrier 3, which has to be supported in a fixed housing (not shown). For this purpose, the differential carrier 3 is provided with sleeve-shaped bearing projections 4 , 5 formed thereon, which serve to receive rolling contact bearings (not shown). The differential assembly 2 forms part of a differential transmission in the drive train of a motor vehicle and is used to transmit torque from a propeller shaft (not shown) to the two side shafts. For this purpose, the differential carrier 3 is provided with a flange 6 formed thereon, to which a ring gear can be fixed in order to introduce torque into the differential assembly 2 .

[0031] The one-piece differential ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com