Floor type air conditioner

An air conditioner, floor-standing technology, applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve problems such as strength reduction, wetting, component cost or installation cost increase, etc., to achieve easy operation, cost reduction, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

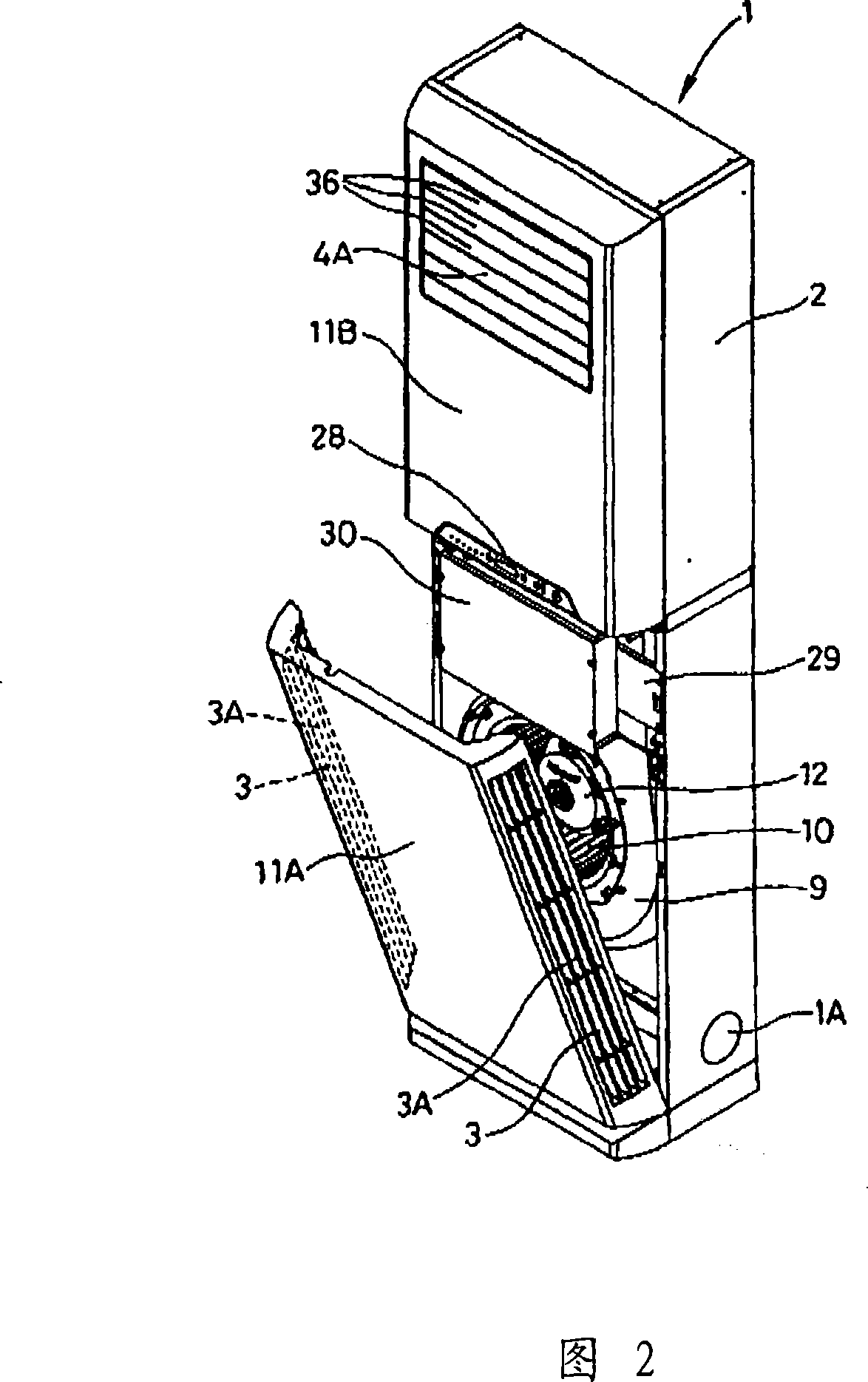

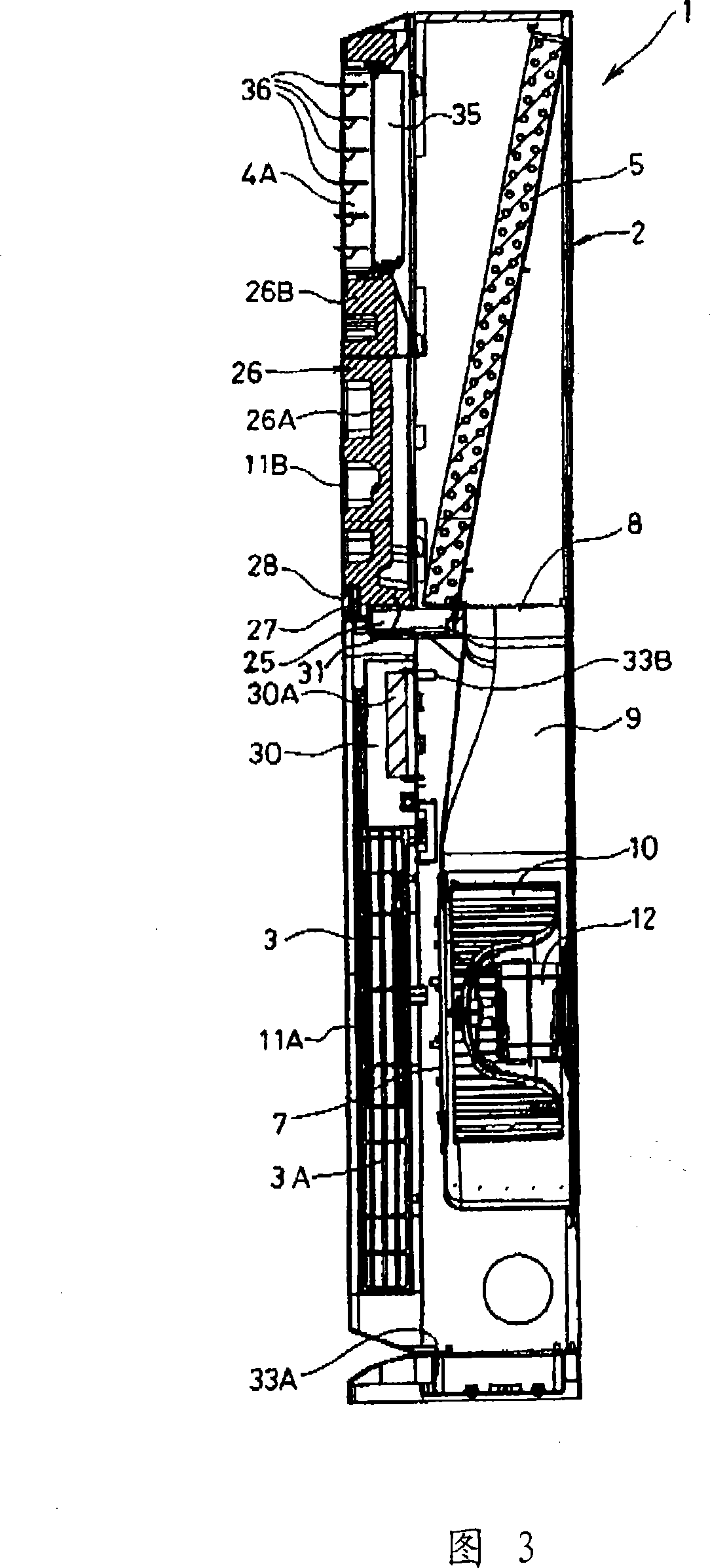

[0070] Next, Embodiment 1 of the present invention will be described. Fig. 1 is a perspective view illustrating the relationship between the floor-standing air conditioner of the present invention and the outdoor unit; Fig. 2 is a front perspective view with the lower front panel of the floor-standing air conditioner of the present invention opened; Fig. 3 is the C-C position of Fig. 1 Fig. 4 is a rear perspective view illustrating the relationship between the air supply device and the front panel of the floor-standing air conditioner of the present invention; Fig. 5 shows the partition of the upper front panel of the floor-standing air conditioner of the present invention The back perspective view under the state of thermal material; Fig. 6 is the sectional enlarged view of the D-D place of Fig. 1; Fig. 7 is the longitudinal sectional side view of the drain pan part illustrating the floor type air conditioner of the present invention; Fig. 8 is a representation of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com