Combined reconfiguration flexible covering stretch forming mold

A stretch forming and combined technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing tooling and shortening construction period, and achieve the effect of reducing quantity, good surface quality and high degree of modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

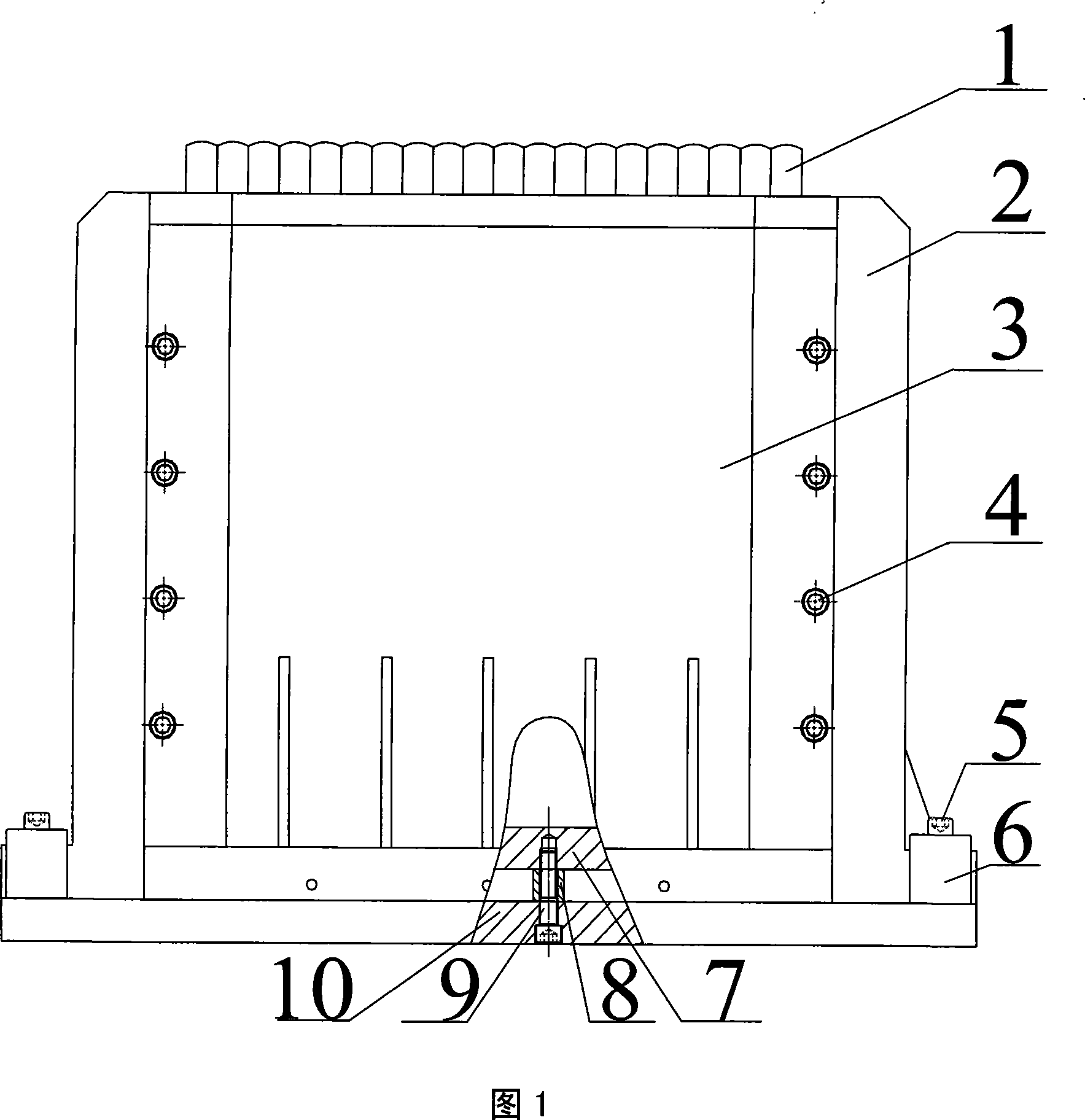

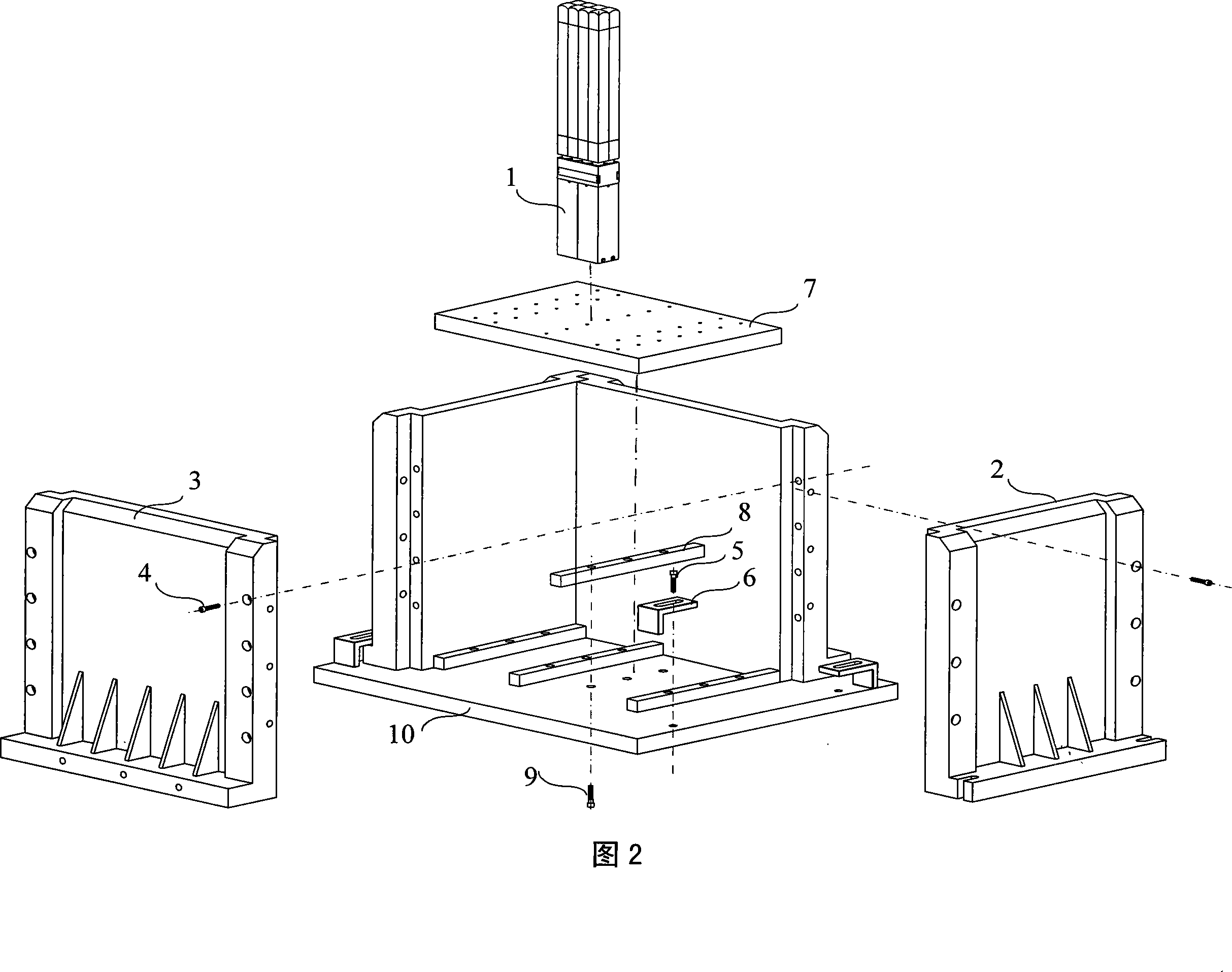

[0033] A combined reconfigurable flexible skin stretch forming die according to the present invention, as shown in Figures 1 and 2, mainly includes a shape adjustment unit, a bottom support positioning unit, a frame fastening unit and an edge fastening unit.

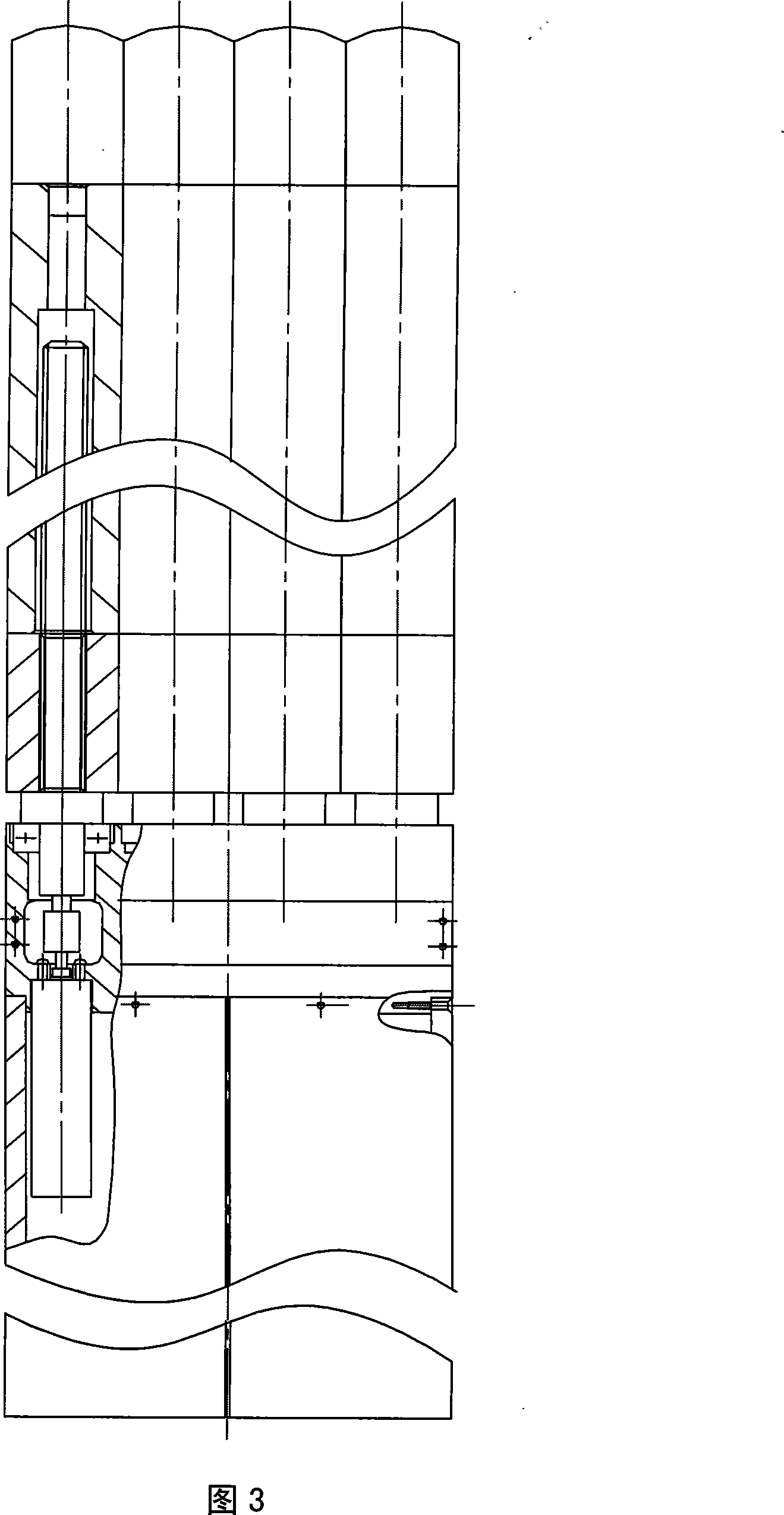

[0034] The shape adjustment unit 1, as shown in Figure 3, is an independent, unitized and adjustable punch movement system, which is a key component of the entire reconfigurable flexible mold. The bottom of the shape adjustment unit 1 and the bottom support positioning unit The positioning plate 7 of the frame is in contact with each other, and each shape-adjusting unit is squeezed against each other. After all the shape-adjusting units are placed, they are fixed by connecting and fastening the large side plate 3 and the small side plate 2 of the frame fastening unit. The shape-adjusting unit is applied for as an invention patent.

[0035] The bottom support positioning unit is a set of positioning and supporting devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com