Method for producing equal edition breadth holographic moulding film and its molding device

A molding and holographic technology, which is applied in the process of producing decorative surface effects, decorative arts, photoengraving process of patterned surface, etc., can solve problems such as error expansion, low precision, and error, and achieve the effect of improving precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

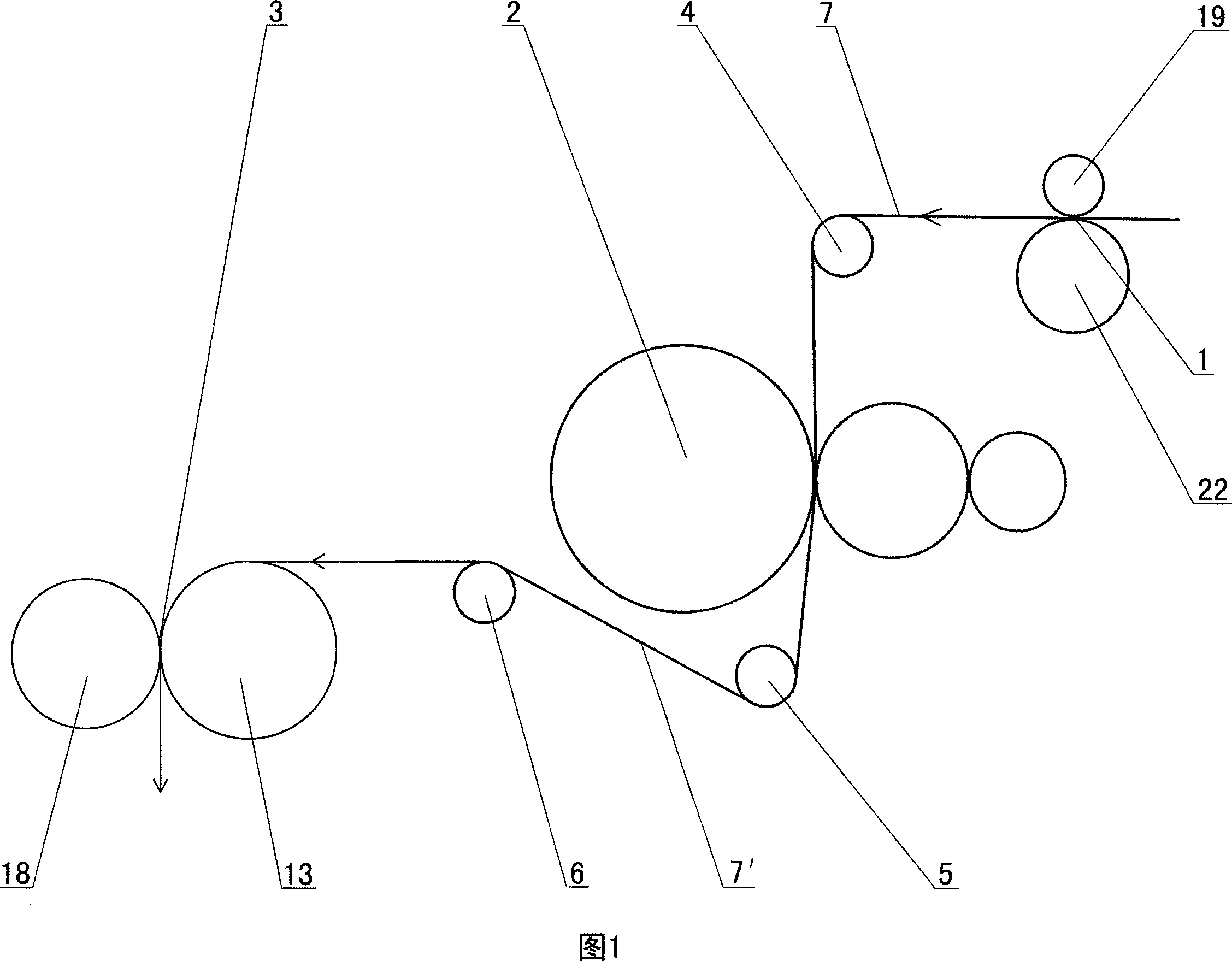

[0032] As shown in Figure 2, a moulding device for producing a holographic moulded film of equal-plate width, the working principle of the moulding device is the above-mentioned method of producing a holographic moulded film of equal-plate width.

[0033] In the preferred embodiment, the molding device for producing holographic molded films of equal format includes an introduction traction roller group 1, a molding roller group 2 and a traction roller group 3 arranged in sequence, one of the molding roller group 2 and the traction roller group 3 There is a guide roller 5 and a tension roller 6 therebetween, and a tension control device is provided on the molding device. The tension control device includes a plate length detection mechanism, a tension actuator and a control system 10. The plate length detection mechanism is located in the molding roller group At the back of 2, the above-mentioned tension actuator is arranged between the lead-in traction roller group 1 and the moldi...

Embodiment 2

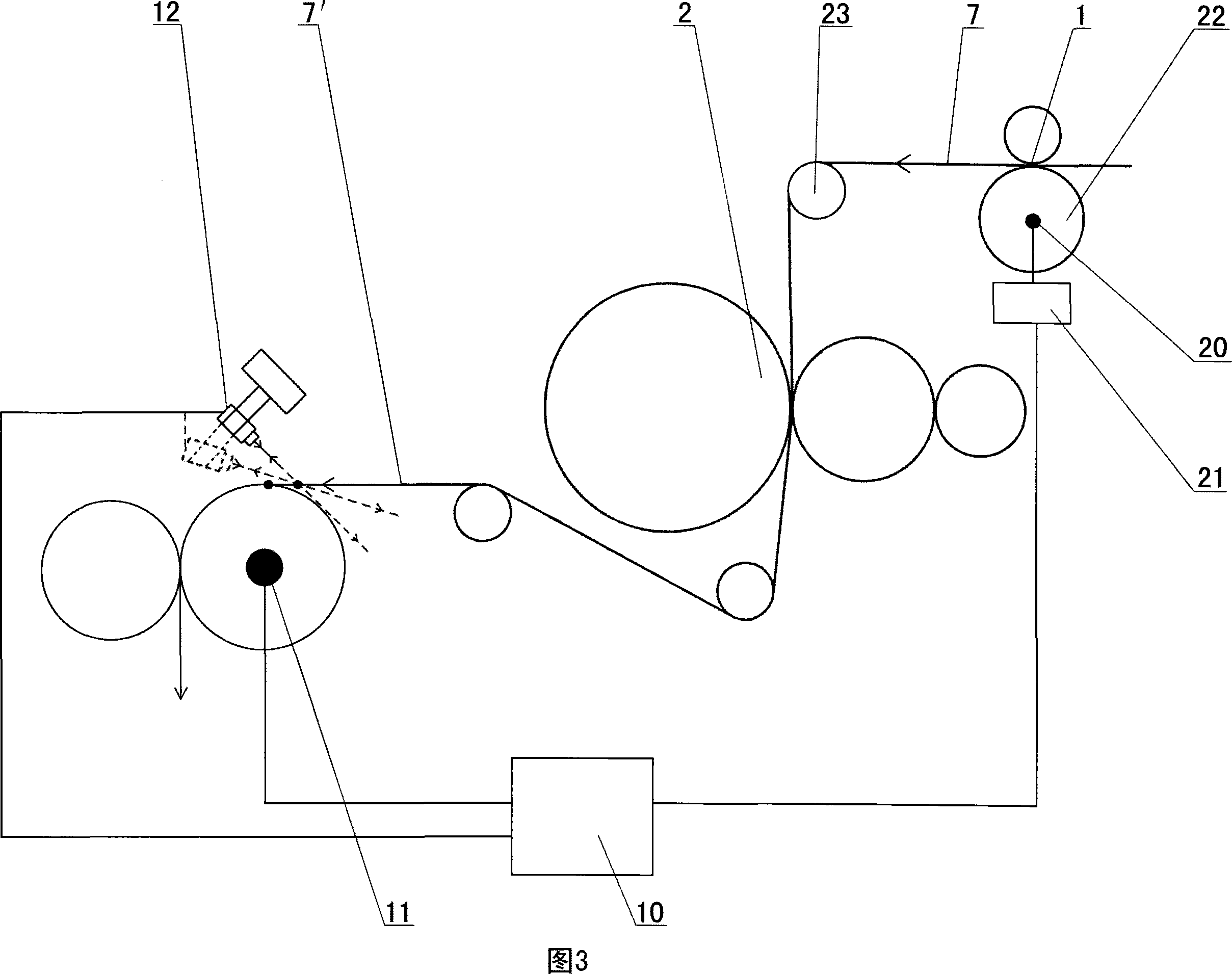

[0042] Embodiment 2 is basically the same as embodiment 1, and the differences between the two are:

[0043] As shown in Fig. 3, the tension actuator of the molding device for producing the holographic molded film of the same format in Example 2 includes a servo control motor 20 and a tension controller 21, the servo control motor 20 and the lead-in traction of the lead-in traction roller set 1 The roller 22 is in transmission connection, and the tension controller 21 is electrically connected to the servo control motor 20; the signal input end of the tension controller 21 is connected to the signal output end of the control system 10; the above-mentioned lead-in traction roller group 1 and the molding roller group 2 are provided Guide roller 23.

[0044] During the molding process, the photoelectric eye 12 of the plate length detection mechanism detects the plate seam signal on the holographic molded film 7', and then sends the detection signal to the control system 10. The contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com