Porcelain brick sticking mould

A ceramic tile and wall sticking technology, applied in the direction of construction and building structure, can solve the problems of increasing labor intensity, increasing difficulty, reducing work efficiency, etc., to reduce labor intensity, improve work efficiency, and ensure neatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

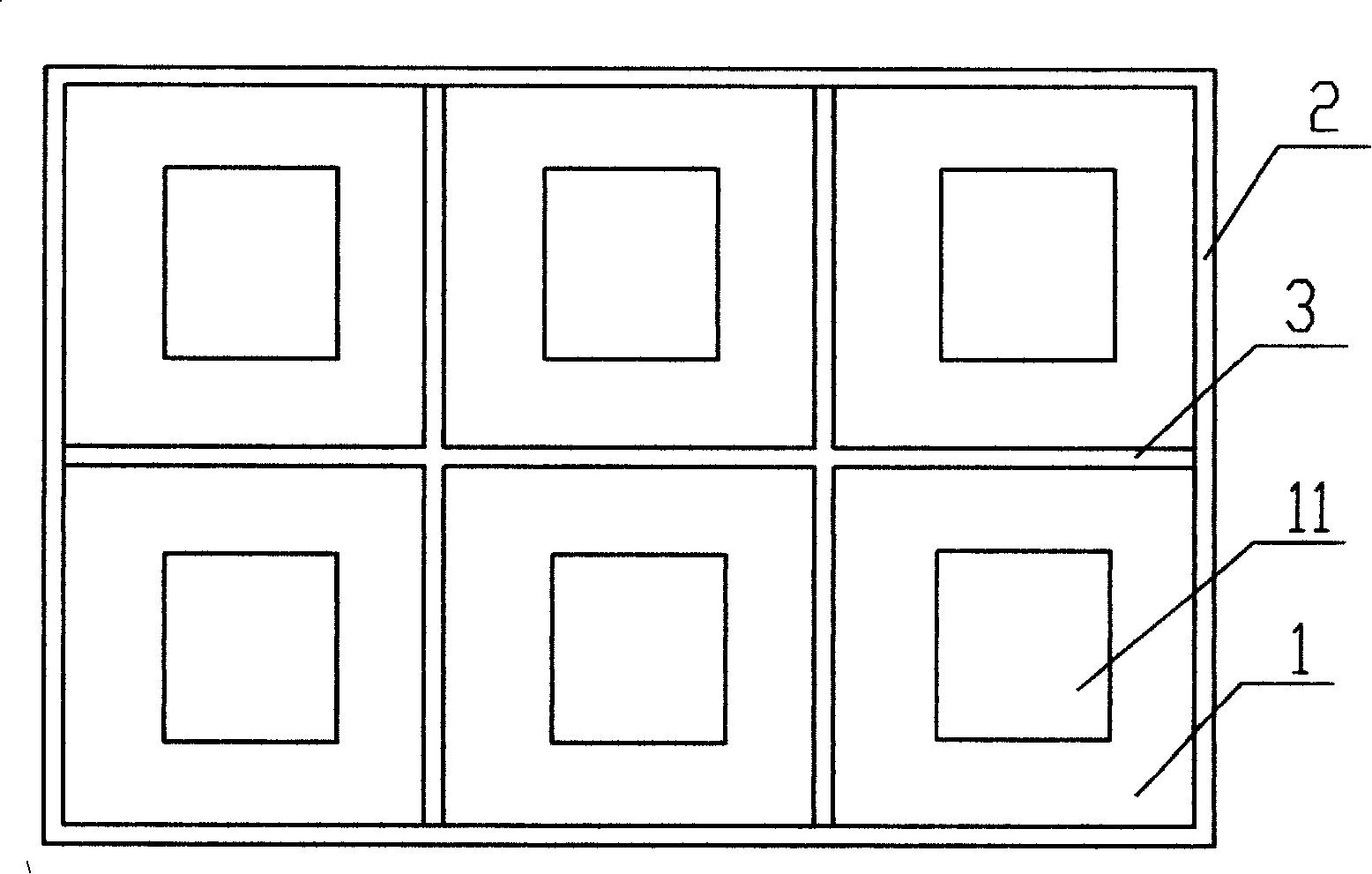

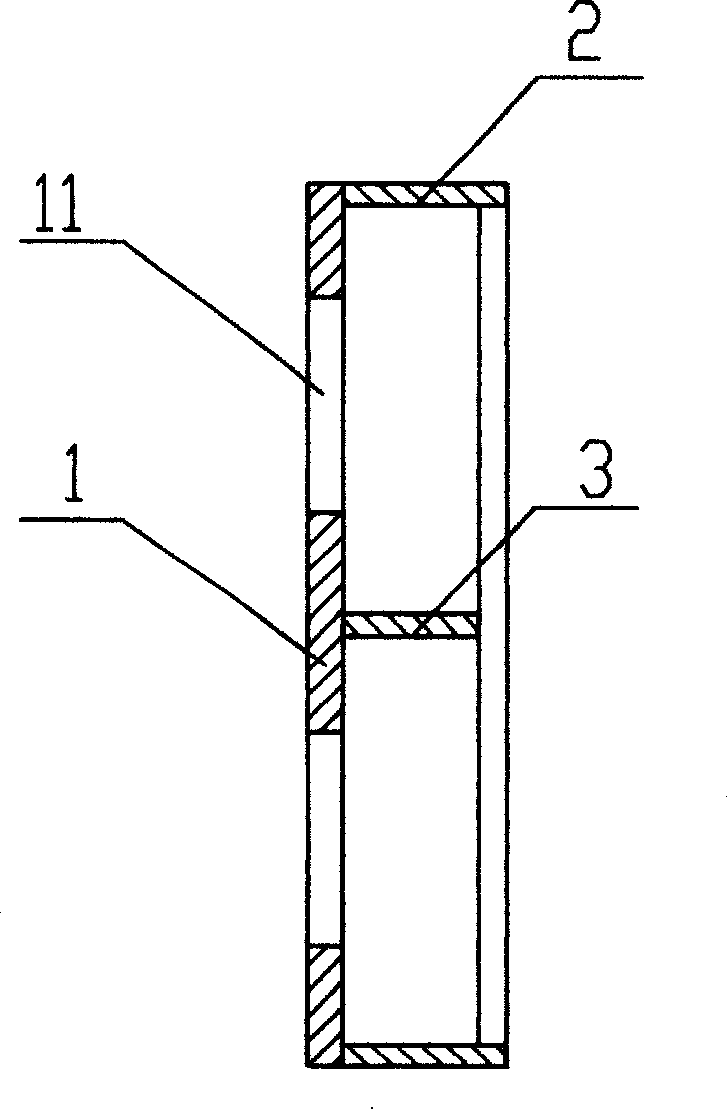

[0010] as attached figure 1 The shown tile wall mould, comprises a bottom plate 1, a frame 2 protruding to one side is provided on the edge of the bottom plate 1, and several partitions 3 arranged vertically and horizontally are installed in the frame 2, and these partitions will The space enclosed by the frame 2 and the bottom plate 1 is divided into a plurality of areas for placing tiles, and the bottom plate 1 is provided with a plurality of openings 11, and the positions of these openings 11 correspond to the areas for placing tiles one by one.

[0011] The height of the frame 2 is higher than the thickness of one plastering layer of the ceramic tile.

[0012] The height of the partition 3 is slightly lower than the height of the frame 2 .

[0013] The working principle of this embodiment is as follows:

[0014] First place the tile wall moulds upwards (mold bottom plate 1 is below), then place each tile in the interval surrounded by partitions 3, spread the grout evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com