Traveling barrel sand-discharging oil-well pump

An oil pump and moving cylinder technology, which is applied in the field of moving cylinder sand discharge oil pump, can solve the problems of easy leakage and insufficient displacement, and achieve the effects of continuously conveying the medium, improving the boosting gear and improving the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

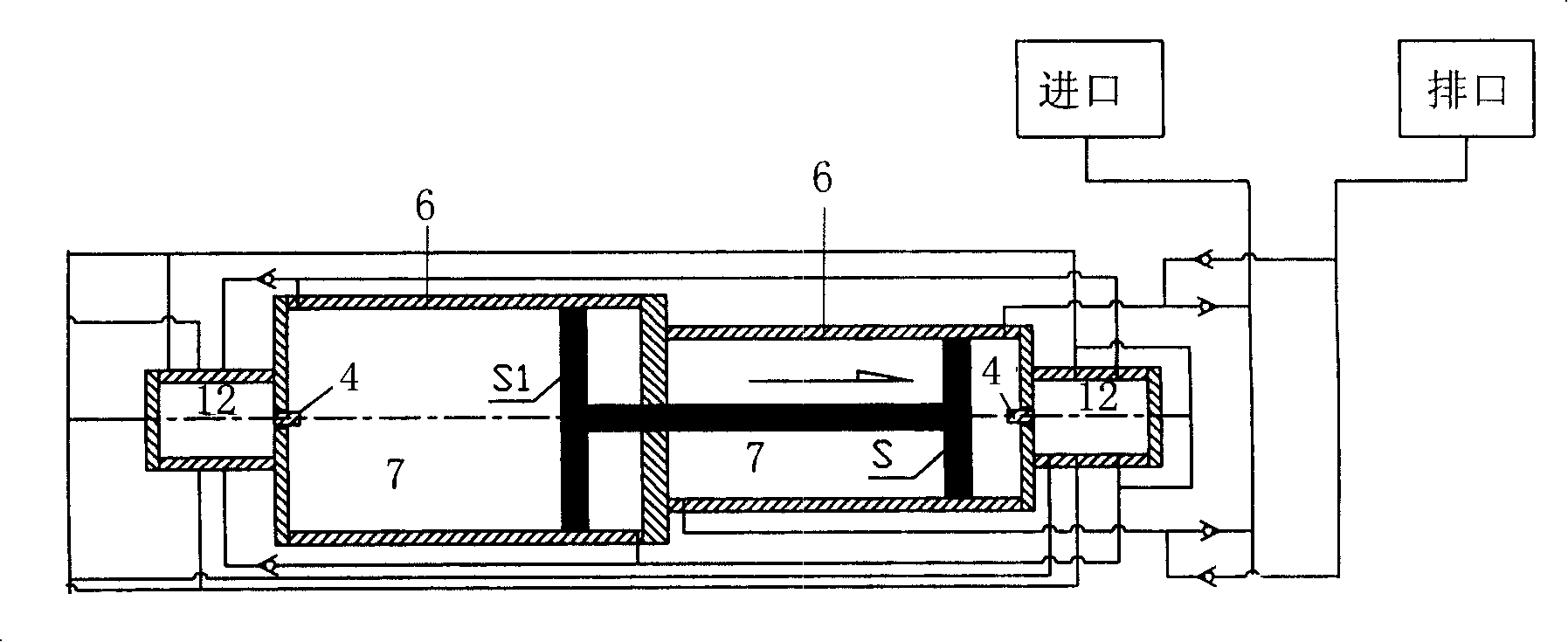

[0013] Below in conjunction with accompanying drawing, specific structure of the present invention is described in detail as follows:

[0014] Such as figure 1 As shown, the two-pole cylinders 6 are connected in series on the same axis line, the pistons of the cylinders 6 are arranged in the cylinder cavity 7, and the two ends of the cylinders 6 connected in series are respectively provided with switching valve groups 12, and the switching valves One end of the contact 4 of the group 12 is set at both ends of the cylinder cavity 7, and a spring 2 is set between the other end of the contact 4 and the inner cavity 15 of the housing 3 of the automatic control switching valve group 12, and the slider 1 runs In the inner cavity 15 , the inner cavity 15 communicates with the pipeline, and the sealing ring 5 is arranged on the contact 4 and the slider 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com