Apparatus for treating chemical fiber waste water by anaerobic method

A technology for chemical fiber and wastewater, which is applied in aerobic and anaerobic process treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high operating costs and difficult treatment of high-concentration wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

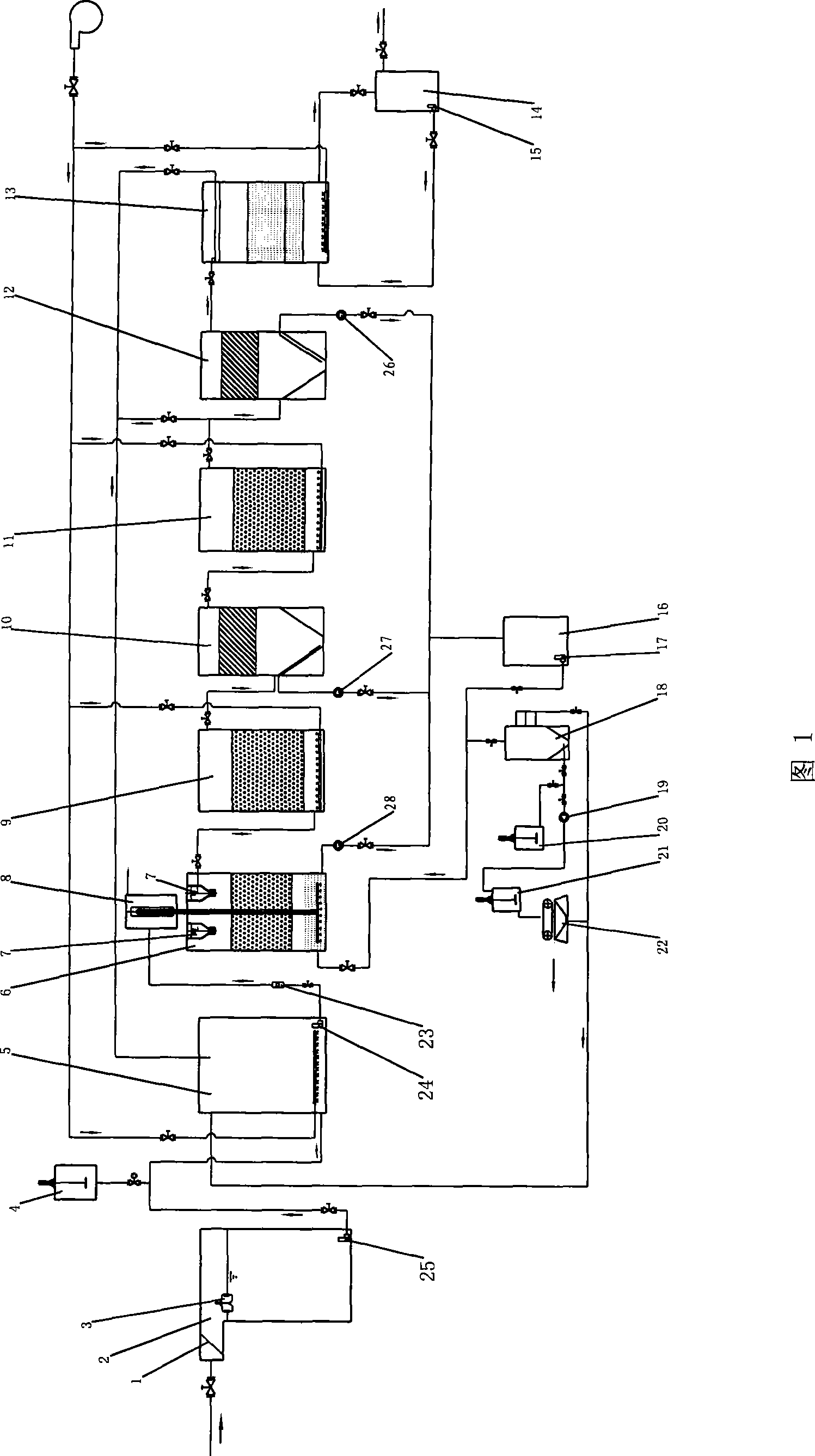

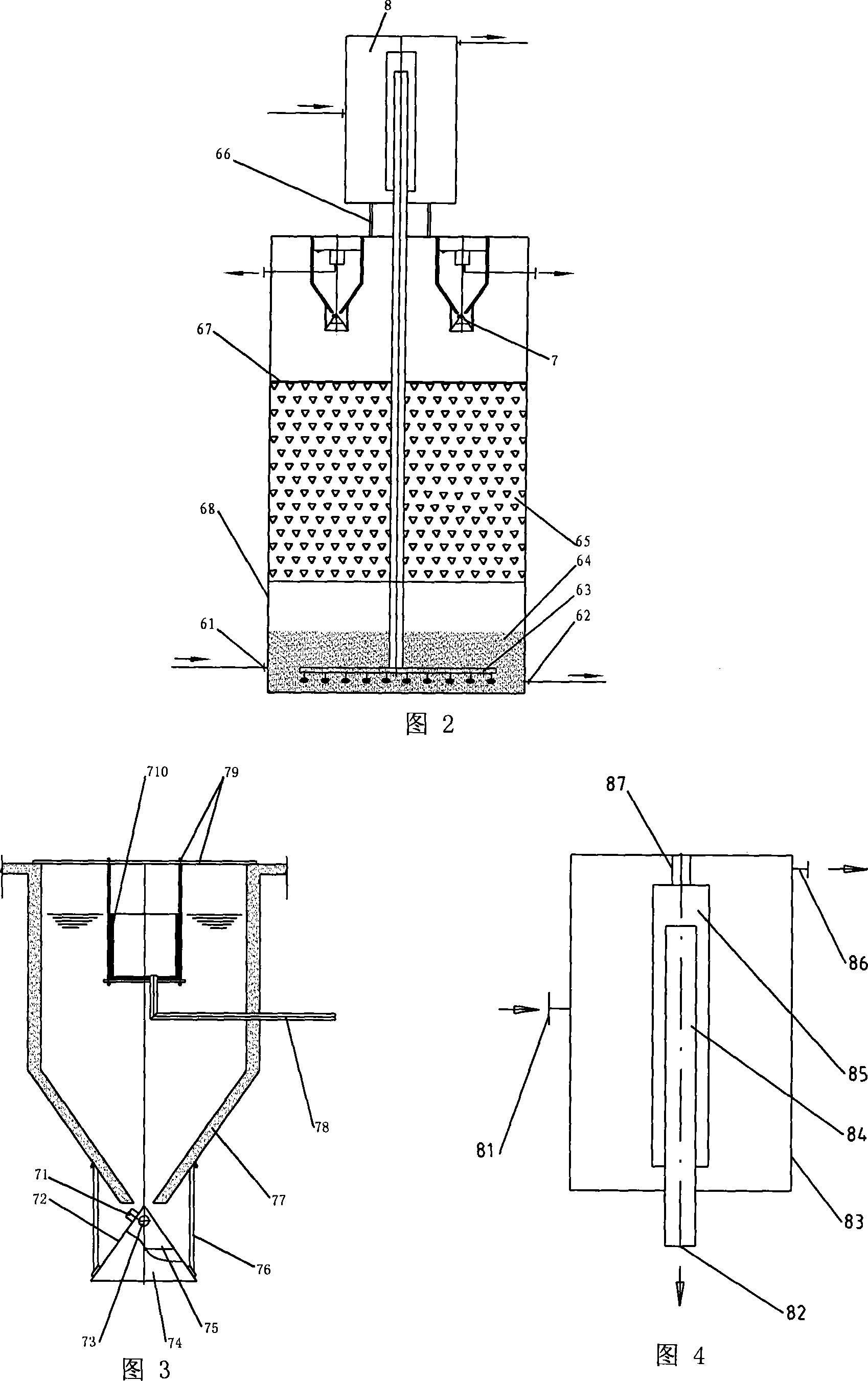

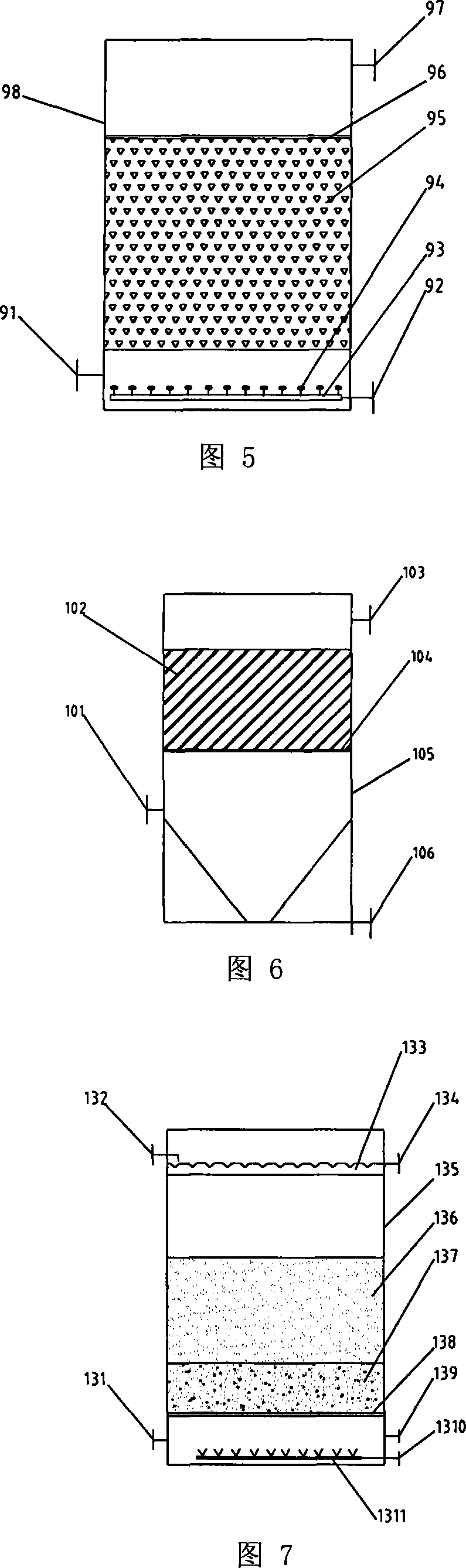

[0022] see Figure 1-7, the present invention is provided with grille 1, water collection well 2, slick oil absorber 3, lye tank 4, regulating tank 5, anaerobic tank 6, three-phase separator 7, flowing water pulsator 8, one-stage biological contact oxidation tank 9. Primary sedimentation tank 10, secondary biological contact oxidation tank 11, secondary sedimentation tank 12, biochar pool 13, clear water tank 14, submersible pump 15, sludge tank 16, submersible sewage pump 17, sludge concentration tank 18 , sludge pump 19, flocculant tank 20, coagulation tank 21, pressure filter 22, flow meter 23, first lift pump 24, second lift pump 25, sludge pump 26, sludge pump 27, sludge pump 28. Valves and pipelines, etc. The grid 1 is arranged at the inlet of the water collection well 2, the floating oil absorber 3 is arranged in the water collection well 2, the second lift pump 25 is arranged at the bottom of the water collection well 2, and the water outlet of the second lift pump 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com