Membrane material for producing coated material and preparation technique thereof

A technology for the production of packaging and film materials, applied in the form of fertilizers, fertilizer mixtures, applications, etc., can solve the problems that natural starch cannot be plasticized, restricts application and development, and has a high glass transition temperature, and achieves storage resistance, easy coating operation, The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

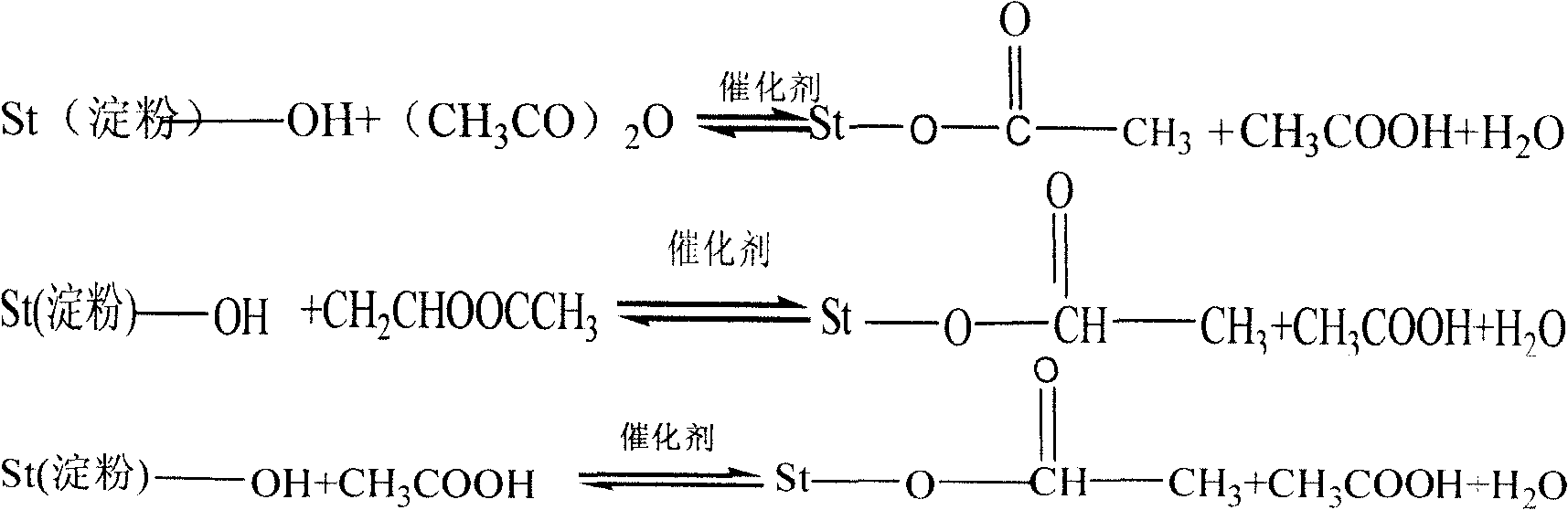

[0025] Preparation process of high degree of substitution acetate starch:

[0026] The preparation methods of acetate starch mainly include wet method and dry method, and the most important preparation method is wet method.

[0027] The wet production process is as follows:

[0028] Starch→starch milk→reagent reaction→washing→dehydration→drying→crushing→packaging

[0029] Dry production process is as follows:

[0030] Starch → reagent soaking → pre-drying → drying → cooling → water adjustment → packaging

[0031]Specific operation: Add industrial high-grade starch into the reaction kettle, add 2 to 20 times of esterification agent, 1 to 50 parts of esterification catalyst solution, stir at the reaction temperature of 30°C to 150°C, and the reaction time is 1 to 50°C. After 9 hours, after the reaction, the pH value was 6.5-10, and then the reaction solution was introduced into excess cold water with vigorous stirring to obtain a white flake-like precipitate, which was fully ...

Embodiment 1

[0037] The acetate starch was prepared with industrial high-grade starch as the main material, acetic anhydride as the esterification agent, and 50% (mass fraction) sodium hydroxide as the esterification catalyst.

[0038] Put 100g of starch into the reaction axe, add 400g of acetic anhydride and 30g of 50% sodium hydroxide, the pH is 9 to 9.5, and react at 123°C for 2.5 hours. , a white flake-like precipitate was obtained, which was fully washed with water, filtered, and dried to obtain acetate starch with a substitution degree of 2.18.

Embodiment 2

[0040] The acetate starch was prepared by using high-grade industrial starch as the main material, acetic anhydride as the esterification agent, 50% (mass fraction) sodium hydroxide as the esterification catalyst and pyridine as the activation medium.

[0041] Put 20g of starch into the reactor, add 30ml of pyridine activation medium, activate at 115°C for 1 hour, add 30g of water for gelatinization, dehydrate at reflux temperature, then put it into the reactor, add 100g of acetic anhydride and 50% Sodium hydroxide 30g, pH 8-8.5, react at 140°C for 1 hour, after the reaction, cool to room temperature, add an equal amount of acetone solution, mix well, introduce 100 times the volume of excess water under vigorous stirring, Immediately a white flocculent precipitate with slight yellowish bands appears, continue to stir to make the product precipitate completely, stand still for a while, wash the precipitate with water, filter until the filtrate is neutral or weakly acidic, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com