Hot gas circulating system for drying room

A circulation system and hot air technology, applied in drying, drying machines, heating devices, etc., can solve the problems of long drying time, poor drying quality of materials, poor effect, etc., and achieve the effect of good drying quality and slow heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

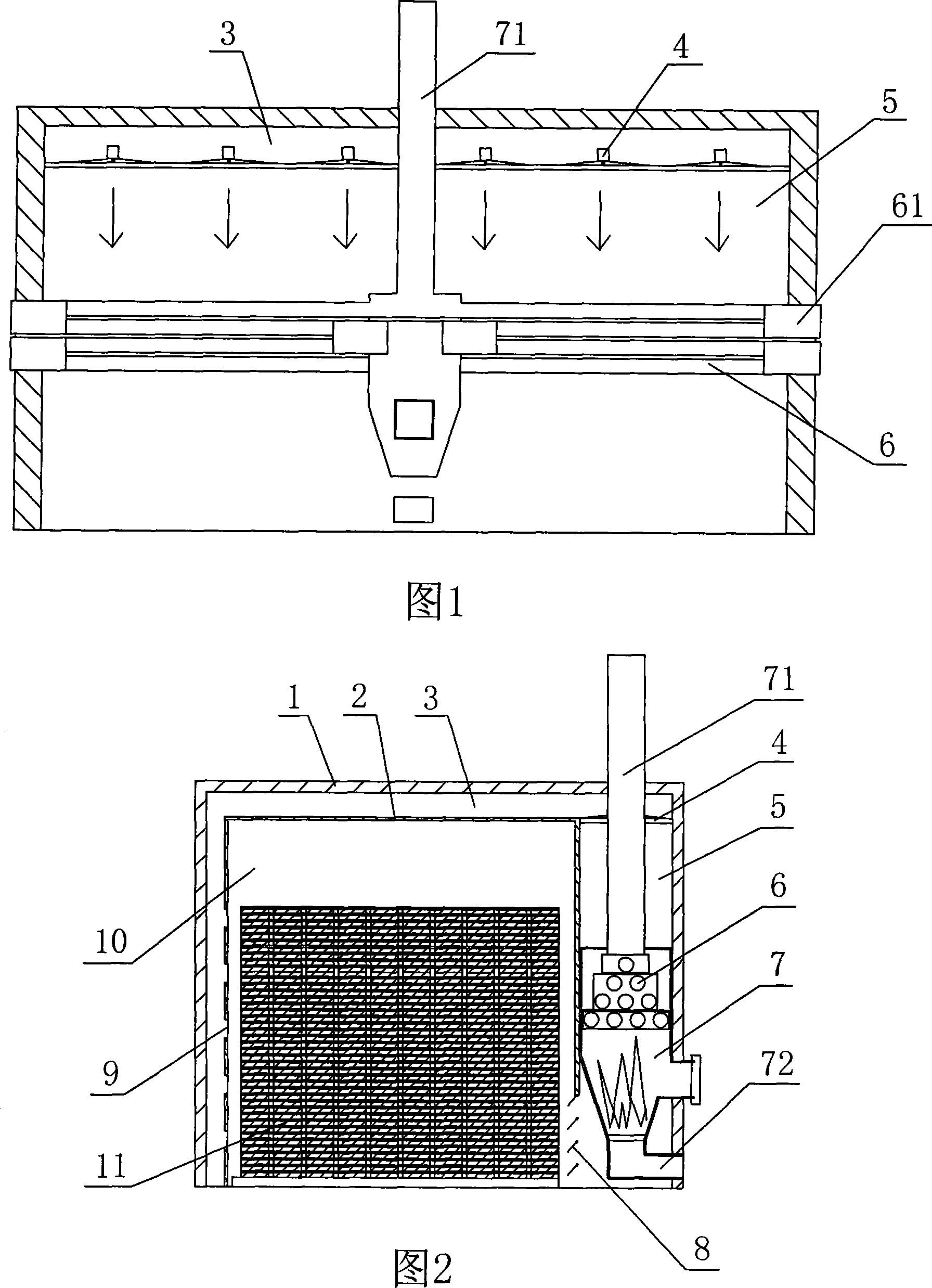

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] As shown in the figure, a hot gas circulation system for a drying room includes a room body 1 and a boiler 7 arranged in the room body 1. The boiler 7 is provided with a chimney 71 and a boiler air inlet 72 respectively communicating with the outside world. The chimney Between 71 and the boiler 7, there are four layers of snake-shaped hot smoke pipes 6 that are arranged more at the bottom and less at the top. Each layer of the snake-shaped hot smoke pipes 6 is disconnected from each other. The ends are sealed and connected by the connection box 61, and the drying chamber 10 for drying the material 11 composed of the inner partition 2 is arranged in the room body 1, and the channel 3 and the hot air are arranged between the inner partition board 2 and the room body 1. Room 5 and boiler 7 are set in the hot gas room 5, and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com