Soft, hard composite three-leveltraction technique for stay cables and connecting device thereof

A technology of soft and connecting devices for cable-stayed cables, applied in cable-stayed bridges, erection/assembly bridges, bridge forms, etc., can solve the problems of long cable-stayed cables, large traction anchoring force, long traction distance, etc., and achieve high work efficiency , simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

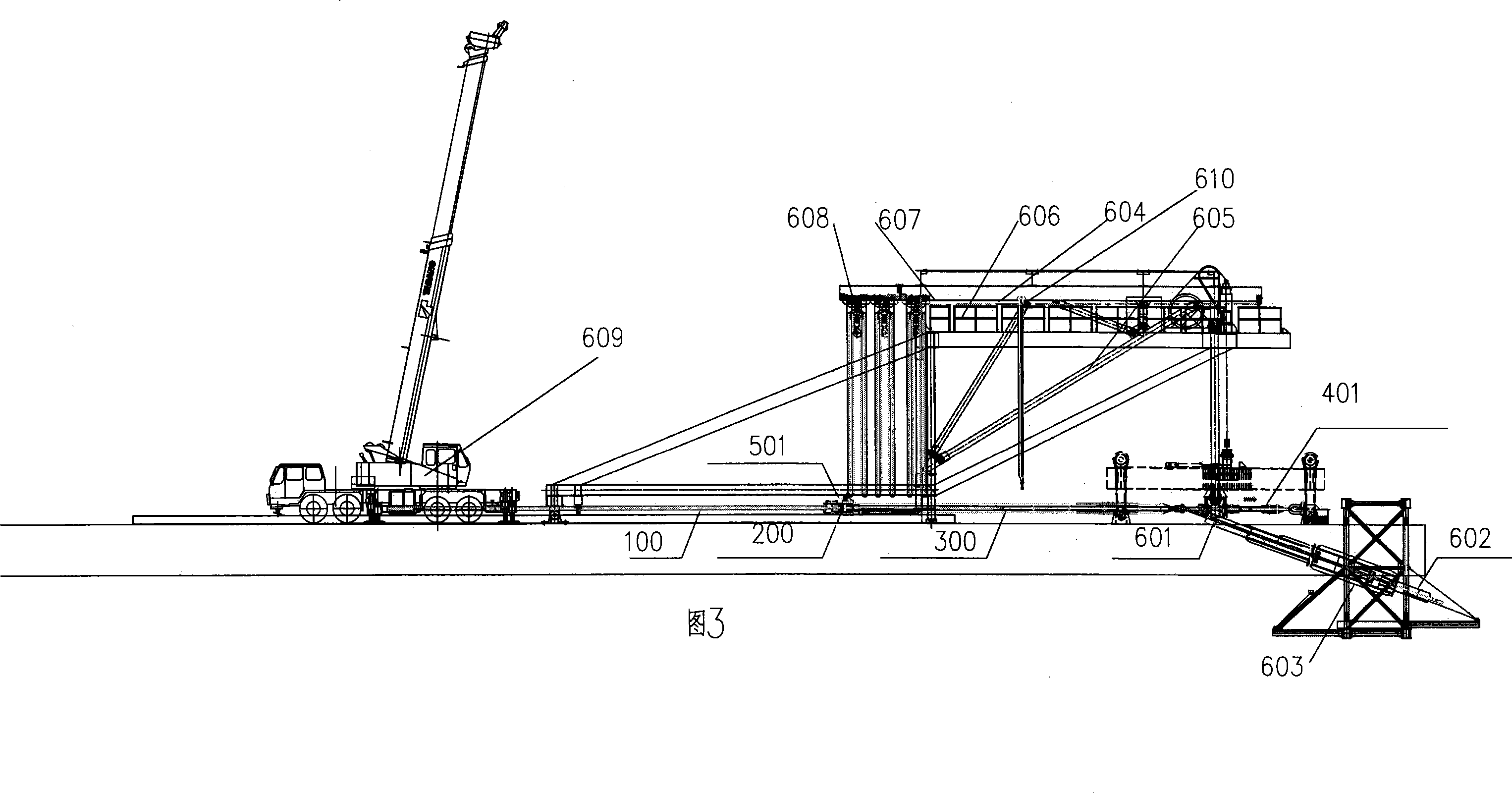

[0017] The traction and anchorage of the long cable (more than 350m in length) in this embodiment is carried out at the end of the beam, and a three-stage traction process combining soft and hard is adopted. The main procedure is: hanging at the tower end of the cable-stayed cable → installing hard traction at the anchor head at the beam end Device→first-level traction (traction force controlled within 60t)→soft traction device installed at the rear of the hard traction device→second-level traction (traction force controlled within 100t)→third-level traction until anchoring.

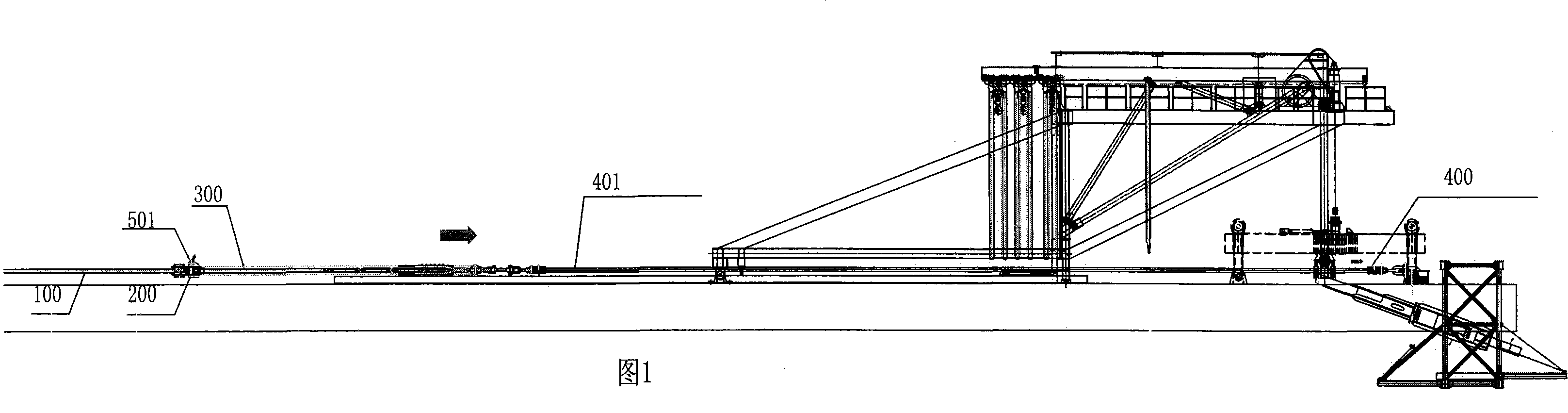

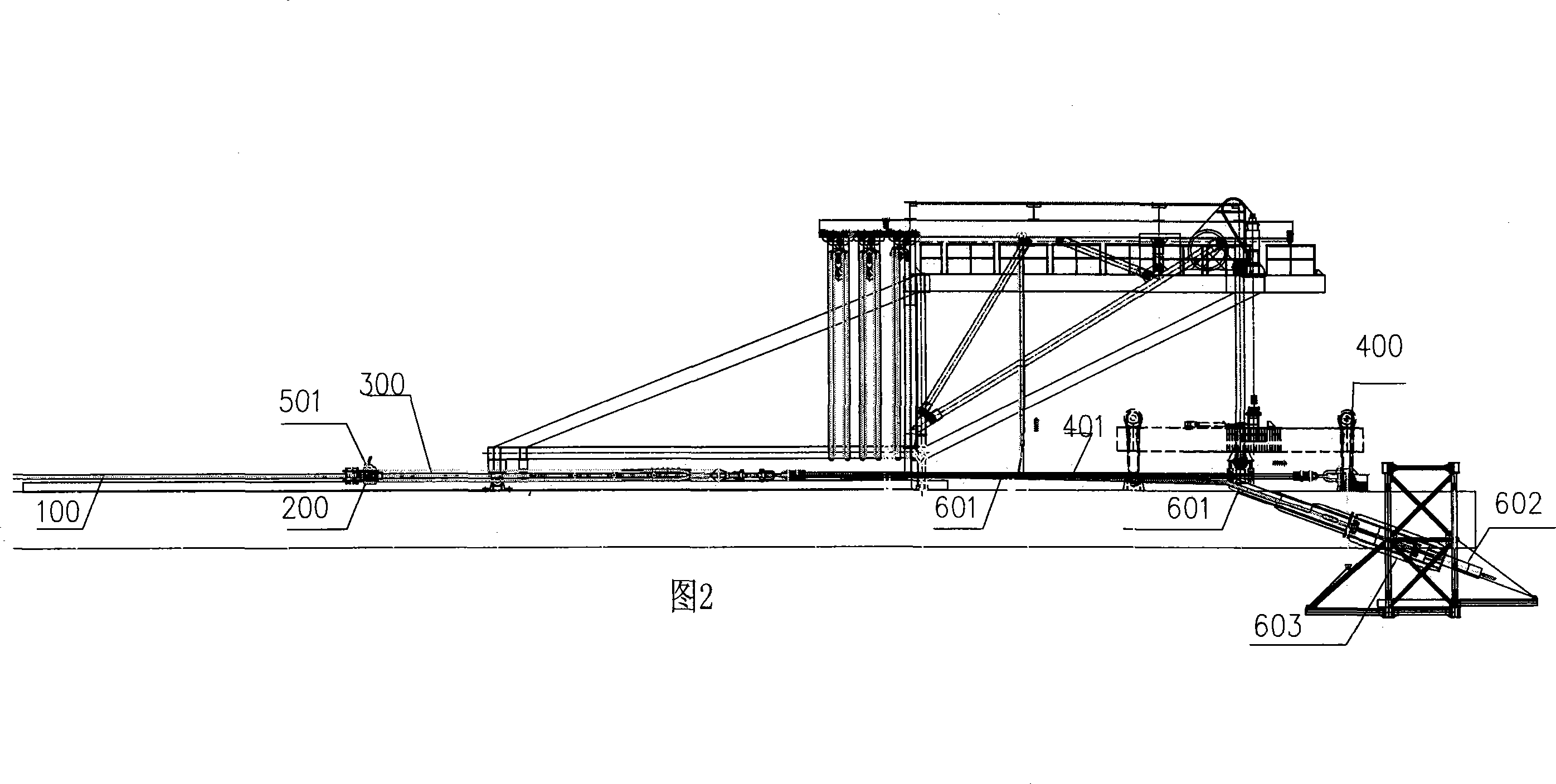

[0018] As shown in Figure 1, a tension rod 300 is installed at the end of the anchor head 200 of the cable beam end of the cable stay cable 100, and the hoist 400 steel wire rope 401 traction device carries out the first-level traction beam end anchor head forward, and the hoist machine steel wire rope is fixed on the tension rod 300 superior. . A lifting jig 501 is set at the joint of the tension rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com