Multi-layer coating product and method for producing the same

A multi-layer coating and product technology, applied in the direction of coating, layered products, layers, etc., can solve the problems of low production efficiency, achieve the effects of improving production efficiency, shortening the time required for debugging laser intensity and scrubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]The preparation method of the multi-layer coated product provided by the invention comprises sequentially forming an undercoat and a top coat on the surface of a base material, the undercoat and the top coat have alcohol resistance, and the colors of the undercoat and the top coat are different , wherein the method further includes forming an intermediate coating between the primer coating and the top coating, the intermediate coating has no alcohol resistance.

[0025] Wherein, the method for forming the primer layer, the top layer layer and the intermediate layer layer can respectively adopt the existing conventional layer preparation method. For example, the coating composition may be mixed with a diluent, applied to a substrate material, and then dried. The mixing weight ratio of the coating composition and the diluent may be 1:0.5-2. The drying method can be various existing methods, preferably drying at 50-60° C. for 5-15 minutes. Described diluent can use the co...

Embodiment 1-5

[0031] Examples 1-5 were used to prepare the coating compositions used to form the coatings.

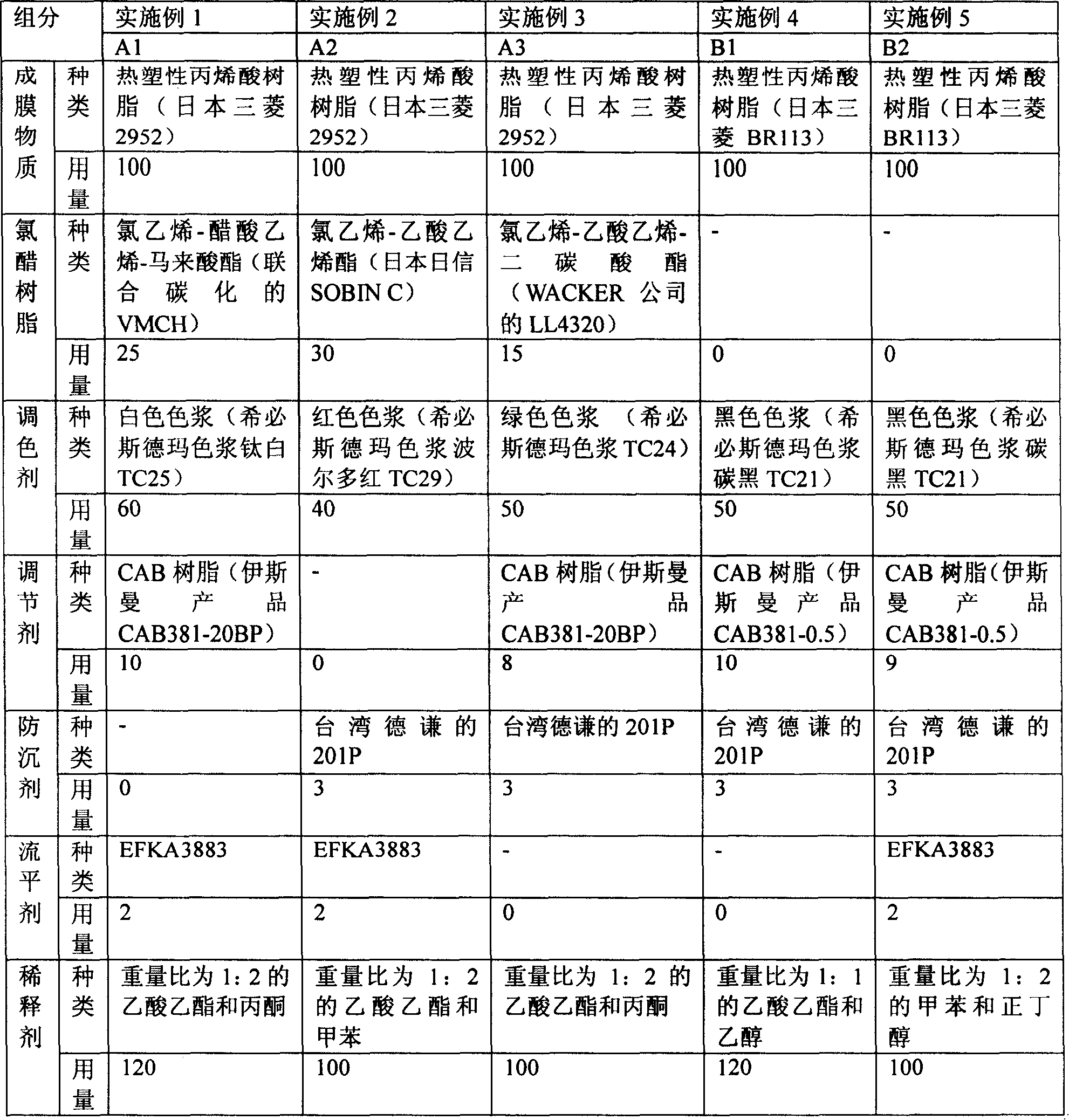

[0032] The components shown in Table 1 were mixed and stirred evenly, and the obtained slurry was filtered to remove the residues therein to obtain coating compositions A1, A2, A3, B1 and B2. The amounts of each component in Table 1 below are expressed in parts by weight.

[0033] Table 1

[0034]

Embodiment 6

[0036] Example 6 is used to illustrate the multi-layer coated article provided by the present invention and its preparation method.

[0037] The coating composition A1 obtained in Example 1 was mixed with ethyl acetate at a weight ratio of 1:0.8, sprayed on the surface of a transparent plastic keyboard, and baked at 60° C. for 10 minutes to form a primer layer. Then, according to the same method, the coating composition B1 obtained in Example 4 and the coating composition A2 obtained in Example 2 were used to sequentially form an intermediate coating and a top coating to obtain a multilayer coating product D1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com