Pump

A technology for pumping and pump casings, applied in the field of pumps, can solve problems such as time-consuming adjustments, and achieve the effects of improving convenience, easy assembly, and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

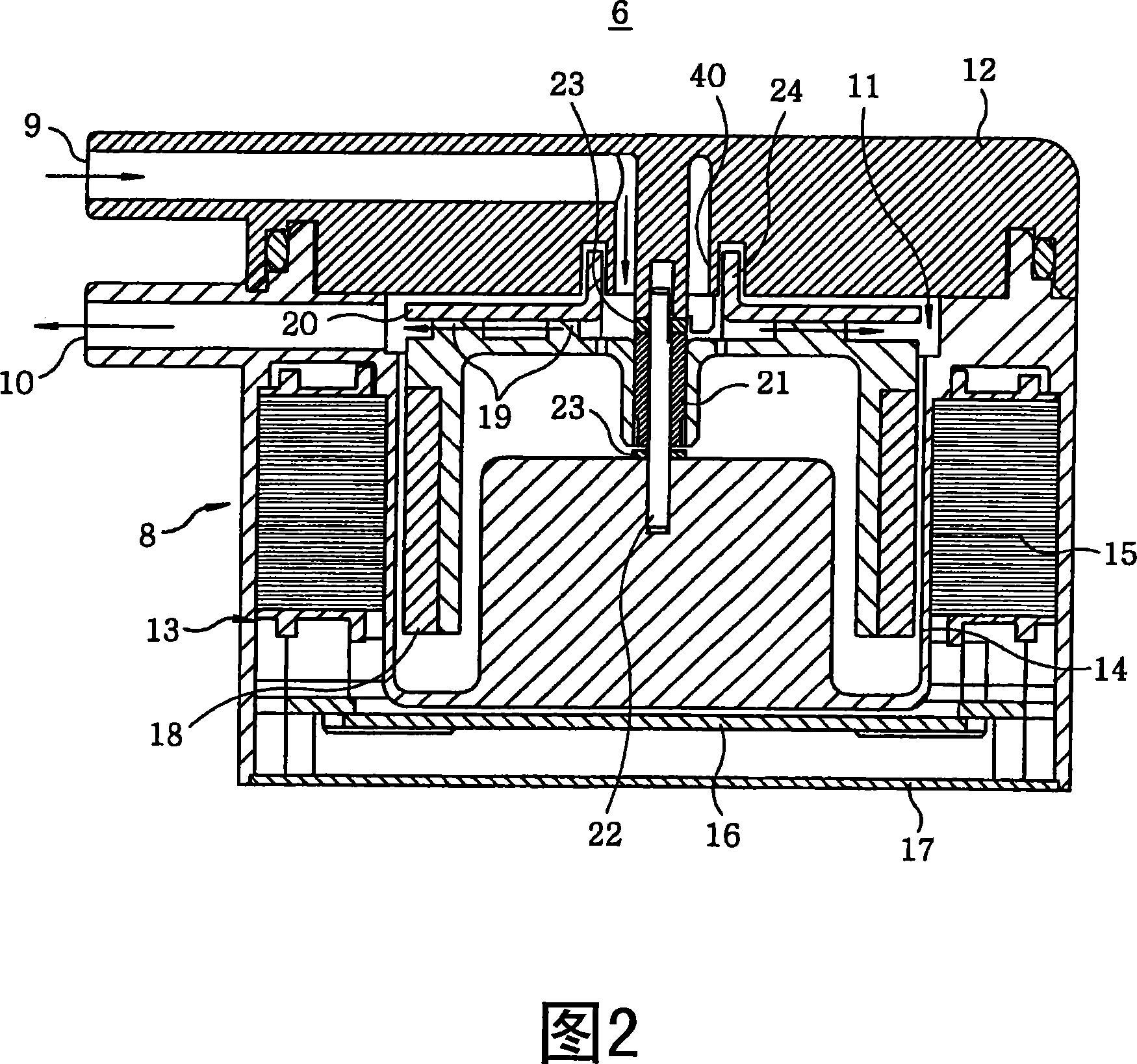

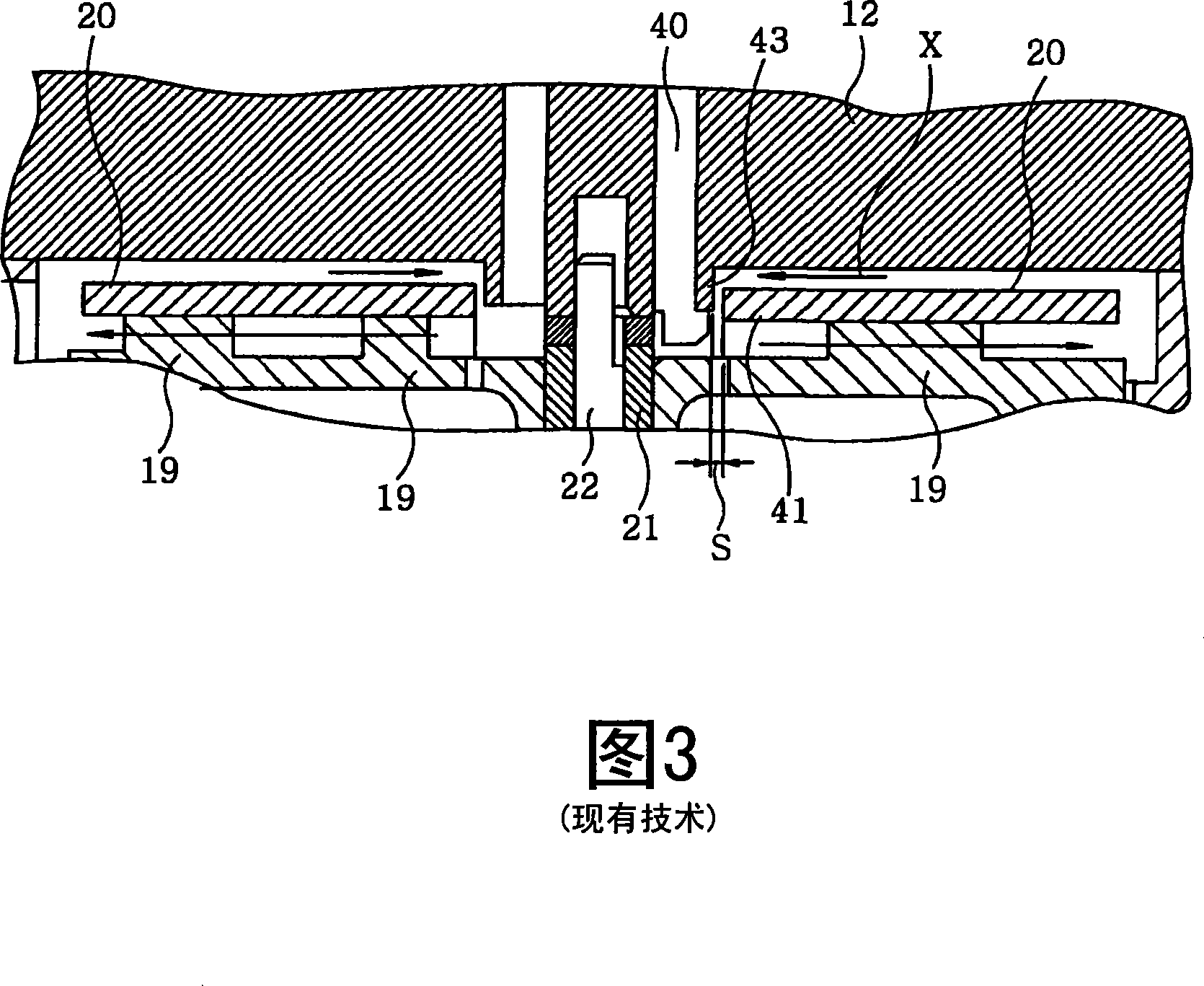

[0027] An embodiment of the present invention, which constitutes a part of the present invention, will be described in detail below with reference to the accompanying drawings.

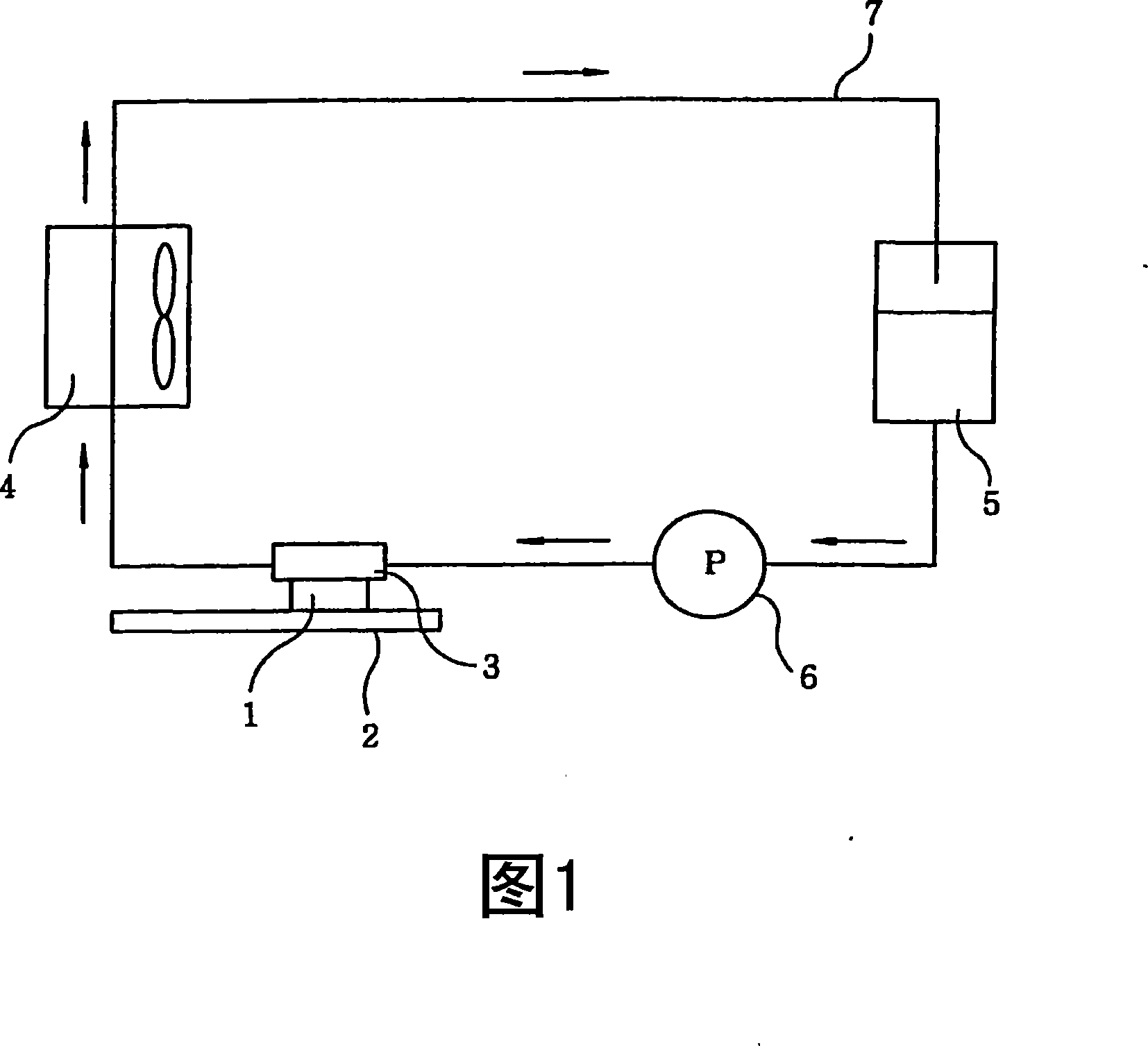

[0028] As shown in FIG. 1, the coolant circulation system includes a heating element 1 mounted on a substrate 2, and a heat sink unit 3 such as a heat radiator for exchanging heat with the heating element 1 using a coolant (such as water) for cooling The heating element 1 is cooled.

[0029] The coolant circulation system also includes a radiator 4 for removing heat from the coolant; a storage tank 5 for storing the coolant therein; a pump for circulating the coolant; and a pipeline 7 for disabling heat The sink unit 3, radiator 4, storage tank 5 and pump 6 are connected.

[0030] The coolant in the storage tank 5 is discharged from the pump 6 through the line 7 to flow into the heat sink unit 3 . In the heat sink unit 3, heat is transferred from the heat generating element 1 to the coolant, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com