Water-proof construction for all-terrain vehicle rear wheel axle

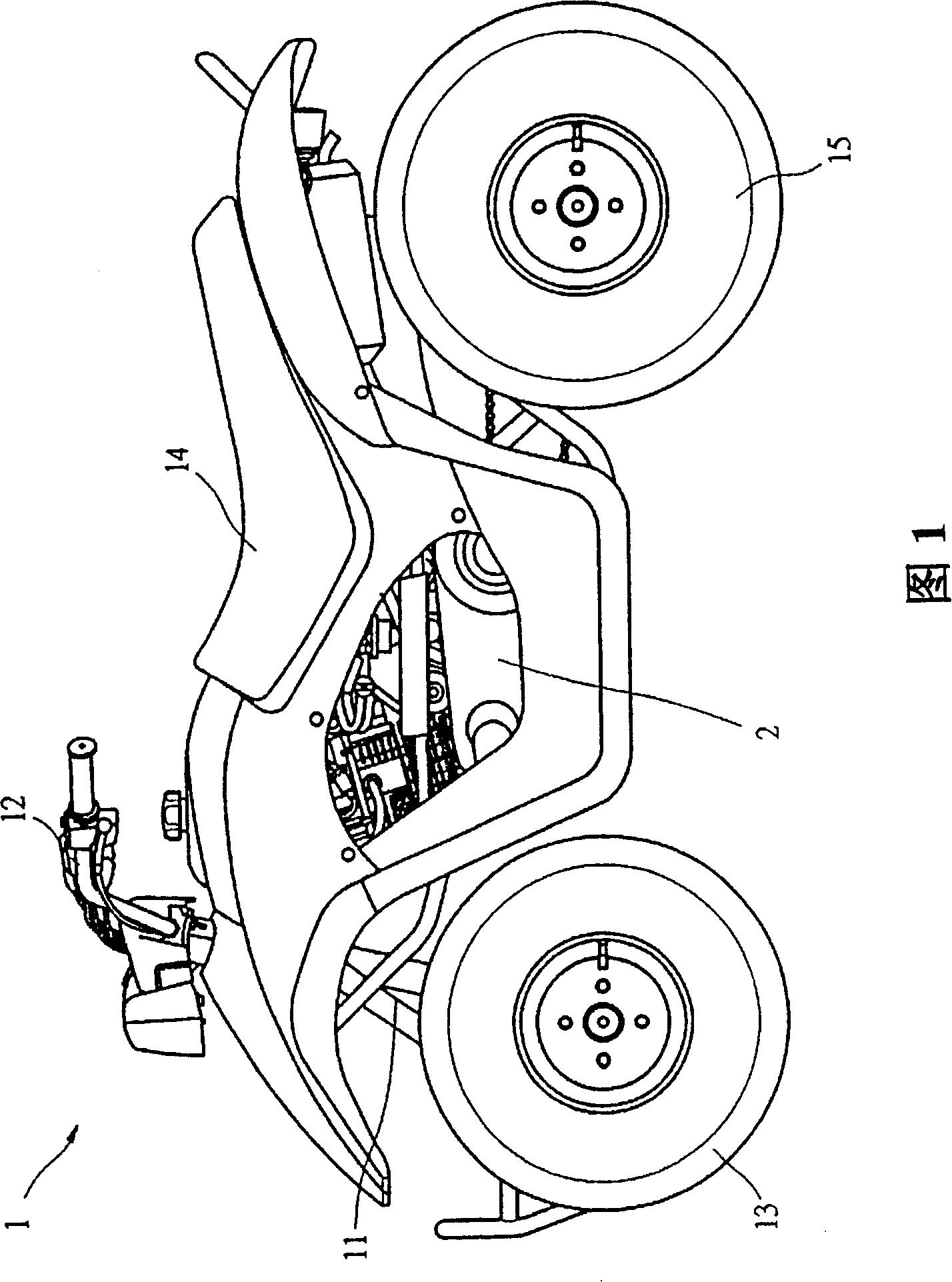

A technology for all-terrain vehicles and rear axles, which is applied to vehicle components, vehicle gearboxes, belts/chains/gears, etc., and can solve problems such as easy scratches, loss of waterproof function of O-ring 42, damage to rear axle 4 bearings 44, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make it easier to understand the structure of the present invention and the effect that can be achieved, it is described as follows in conjunction with the drawings:

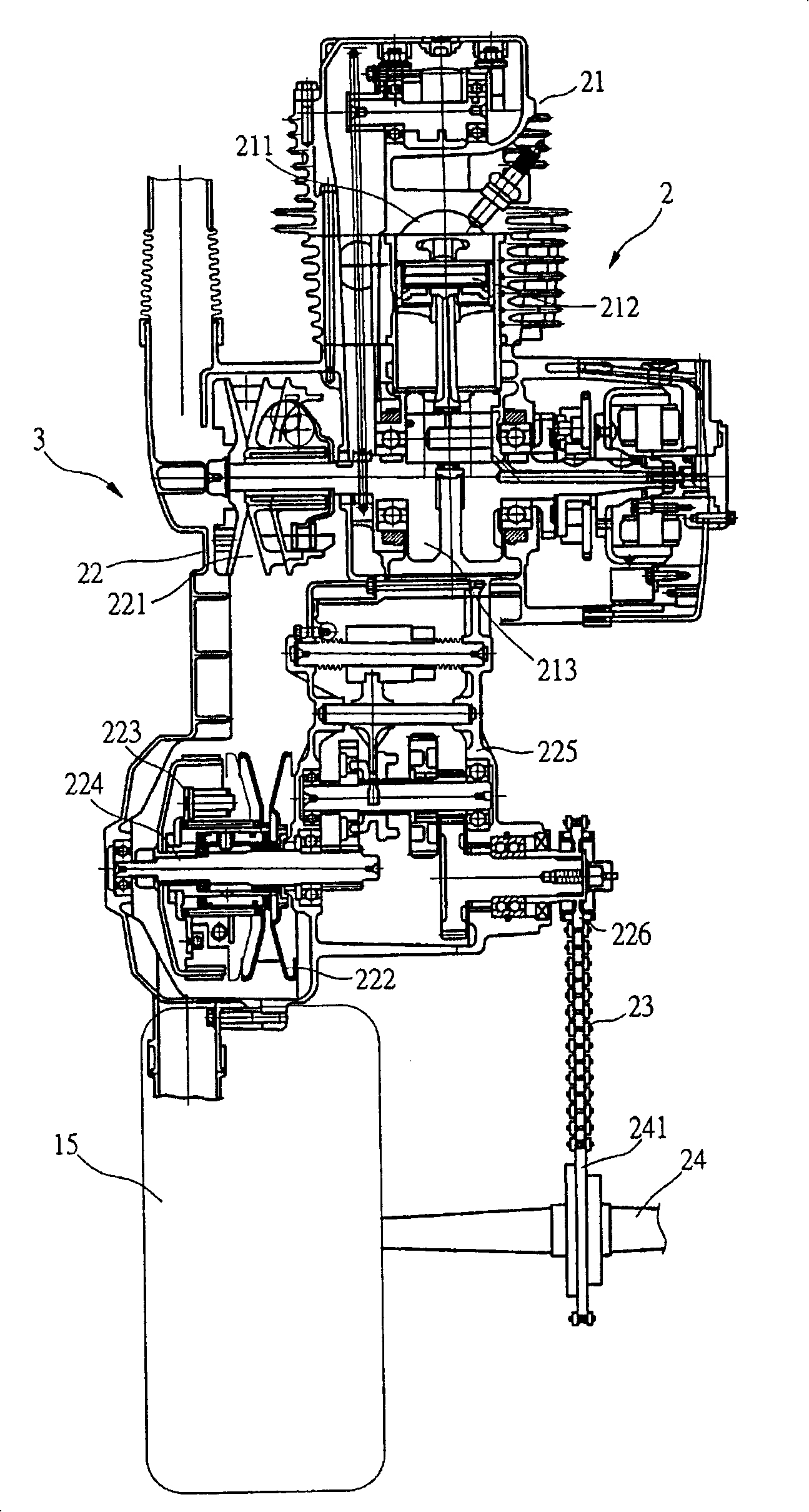

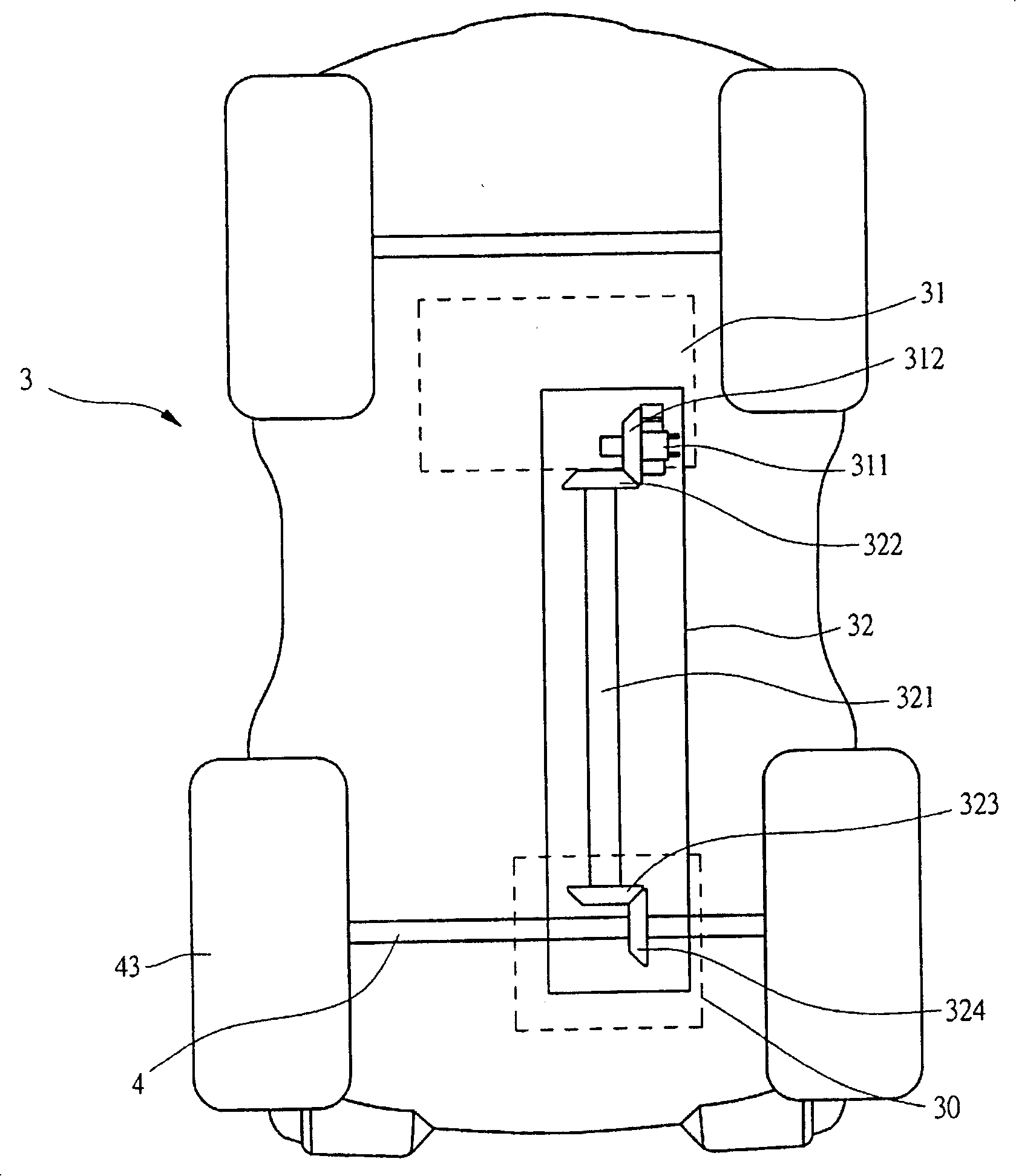

[0019] Please first refer to Figure 5, Figure 6 As shown, the rear axle waterproof structure 5 of the all-terrain vehicle of the present invention has a gear box 52 on the rear axle 51 .

[0020] The gear box 52 is for the rear wheel shaft 51 to be worn. The gear box 52 is provided with the bevel gear 62 of the shaft transmission mechanism 6 transmission shaft 61. Engage vertically, wherein, the bevel gear 63 extends to one side of the rear wheel shaft 51 with a receiving edge 631, the receiving edge 631 extends out of the gearbox 52, and the receiving edge 631 has an annular recess 632, and the other A dustproof sleeve 64 is sheathed on the receiving edge 631, and the dustproof sleeve 64 can be prevented from falling off by the concave portion 632; Dust sleeve 64 for better fastening.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com